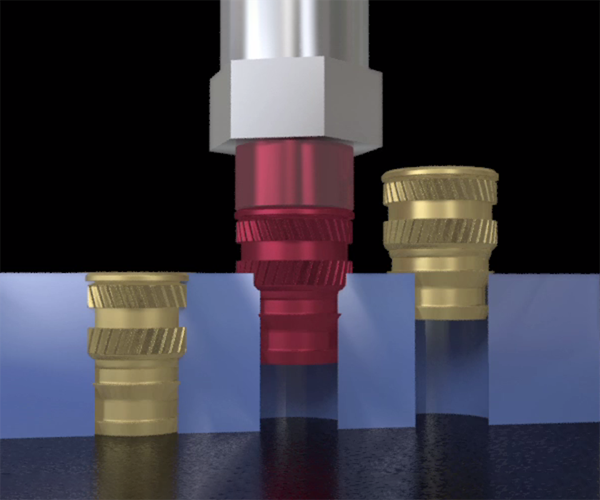

Heat Staking Vs. Ultrasonic Threaded Inserts

Sponsored ContentThreaded inserts installed with heat or ultrasonics provide plastics processors with high performance at a low cost. Discover when to use them and how.

Share

Both heat staking and ultrasonic processes for installing threaded inserts can be used by plastics processors looking for strong joints and reusable threads.

Both heat staking and ultrasonic processes for installing threaded inserts can be used by plastics processors looking for strong joints and reusable threads.

Heat-staking and ultrasonic insertion starts with a pre-formed hole that can be formed in the molding process or drilled afterwards. With heat staking, heat is applied to the threaded insert, softening the plastic as it is pushed into the part. Alternatively, ultrasonics uses a vibration frequency to soften the plastic for thread insertion.

Both types offer high overall performance for thermoplastics applications, but require a few careful considerations…READ MORE.

(2).jpg)