Market Trends in Polymer Additive Manufacturing

Unlike the BetaMax/VHS technology debate, all the established polymer print technologies have a viable long-term role to play in the 3D-printing industry.

SmarTech Publishing has two new studies on additive manufacturing trends. The Crozet, Va.- based firm is said to be a leading provider of industry analysis and market forecasting data to the additive manufacturing industry. Here are highlights of the two reports:

● Polymer Additive Manufacturing Trends 2018: This report provides market data and analysis of market trends at the professional and industrial level. Readers will learn how the polymer 3D printing opportunity in material extrusion, photopolymerization, powder bed fusion, and jetting cuts across numerous user industries. The report covers market shipments, sales, installations, and future forecasts through 2027, providing insight into the future polymer 3D printing.

In 2018, the polymer additive manufacturing market is increasingly segmented between several leading print processes, all of which are developing into significant global technology markets for manufacturing. The company believes that a proper understanding of the opportunity in polymer 3D printing technology requires both a deep understanding of the individual nature of each widely adopted polymer print technology, but also an understanding of the interrelationship between these technologies and how those are all growing as a whole to create an industry.

Companies developing materials, software solutions, and ancillary post-processing or automation technologies for polymer 3D printers have come to understand that, unlike the great BetaMax/VHS technology debate of decades past, all of the established polymer print technologies have a viable long-term role to play in the growth of the 3D printing industry. As a result, companies such as DSM, BASF, Henkel, Siemens, Dassault Systemes, and many more continue to develop solutions for multiple print processes.

● Polymer Material Extrusion Market Poses $2.2B Revenue Opportunity

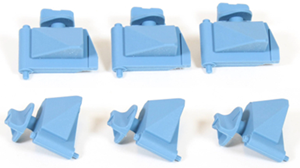

This report addresses the polymer material extrusion market, commonly known by the Stratasys trade name FDM. It is projected to generate the most revenues in polymer 3D printing hardware used in professional and industrial environments through at least 2024. By 2027, the polymer material extrusion market of non-hobbyist and consumer users will generate $2.2 billion in printer and hardware sales alone.

In 2017, material extrusion 3D printing technology generated the greatest amount of revenues for 3D printers—more than other polymer printing processes such as powder bed fusion and vat photopolymerization. About 70% of those revenues was associated with low-cost desktop and consumer extrusion printers. This segment features printers ranging from lower-end Stratasys products like the Mojo, uPrint, and F170, to the entire product range of companies like Ultimaker, Aleph, Objects, Leapfrog, Zortrax and many more.

From a competitive standpoint, material extrusion 3D printing technology is mostly controlled by a single company—Stratasys. However, the dynamics of the market have continued to change significantly over the last several years. Not only have new entrants become more established with business models in selling printing solutions exclusively to professional users (such as Cincinnati, Inc.), but perhaps more notable has been the number of companies that has transitioned from marketing low-cost printers primarily to consumers and educational customers to making systems for more manufacturing and business-oriented use.

These companies have indeed eroded Stratasys’ overall market share in the polymer material extrusion market in professional environments over the last several years. For example, in the first quarter 2018, multinational manufacturer Bosch made an investment in Dutch provider Ultimaker, which will become a worldwide supplier to Bosch with extrusion-based printing solutions. Just five years ago, it would be relatively unheard of for a multinational company of that size to engage at such a broad levels with any other extrusion 3D printing solution provides than Stratasys.

Related Content

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreHow Additive Manufacturing Can Help, not Hinder, Injection Moldability of New Designs

Four cost drivers—design for moldability, mold-base size, internal componentry, polish/custom finishing—dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding its potential pitfalls.

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

(2).jpg;maxWidth=300;quality=90)