SPE Auto Div. Names Hall of Fame and Lifetime Achievement Winners

GM's 1984 Chevy Corvette and experts in automotive composite materials will be honored at the 45th SPE Automotive Innovation Awards Gala next month.

For the second year in a row, I had the pleasure of participating as a judge for the SPE Automotive Division 2015 Blue Ribbon Automotive Innovation Awards Competition. I plan to report on the winners of the nine categories and will also blog about all the final nominees for each category in the near future as they all merit it. Meanwhile, SPE has announced both the winners of its 2015 Hall of Fame award and its Lifetime Achievement Award--all of which will be honored at the 45th-annual SPE Automotive Awards Gala on November 11th in the Detroit area.

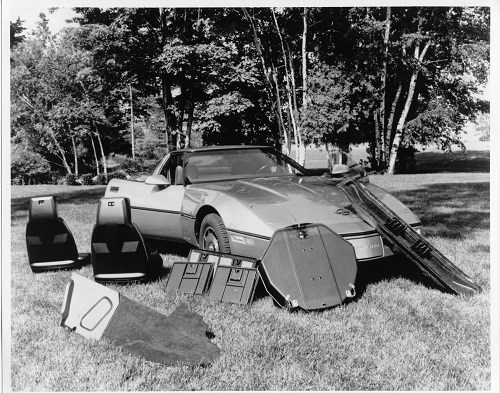

• Hall of Fame award: So, this year’s award goes to GM’s 1984 Chevrolet Corvette sports car which featured the first use of glass-mat thermoplastic (GMT) composite on its front bumper. To be considered for this award, an automotive plastic or composite component must have been in continuous service in some form for at least 15 years and preferably have been broadly adopted within the automotive or ground transportation industries.

“The front bumper on the 1984 Corvette not only was the first in a long line of weight- and cost-saving front and rear end bumper beams in GMT composites, but it also led to increased use of GMT as well as other thermoplastic composites in a broad range of interior and exterior automotive applications worldwide,” explains Nippany Rao, president of RAO Associates, and co-chair of the SPE Automotive Div. Hall of Fame committee.

That first GMT bumper was a two-piece, compression-molded, induction, welded, box-section design using Azdel Inc.’s Azdel PM 400 40% continuous-strand, randomly oriented glass fiber in a PP matrix from PPG Industries. Molded by LOF Plastics, Inc., this application also represents the first use of EMA weld welding from EMAbondSolutions LLC. Versus steel, the incumbent bumper beam material at the time, GMT composite beams offered such benefits as 30% lower weight, greater design flexibility, lower tooling costs, elimination of rust/corrosion, and better impact performance during low-speed impacts.

Shortly after the Corvette bumper’s commercial debut, GM launched C-section GMT designs on the front bumper of the D-body platform, which included models like the Cadillac DeVille, Fleetwood, and Brougham sedans. Another C-section design was used on Cadillac Seville sedan. By 1986 and 1989, respectively, Ford and Honda adopted GMT bumpers for both front and rear. During the 1990s over 16% of all passenger cars globally sported GMT bumper beams. In 1998, we saw the development of the I-beam—the first GMT bumper to use a new discontinuous chopped-fiber mat.

By 2000, South Korean GMT producer and Azdel licensee Hanwha was developing GMT beams for all Korean passenger car models, and still supplies to these OEMs. GMT bumpers also proliferated on vehicles produced by European automakers, including PSA Peugeot Citroen Group and Fiat Group.

• Lifetime Achievement Award: This year’s award goes to Frederick (Fred) Deans, a pioneer in the development of automotive composites applications. Deans has over 45 years’ experience at companies like Continental Structural Plastics, Azdel, GE, and PPG, working in the automotive, architectural, and industrial market segments. Deans is an expert in composite material and molding processes, product engineering, specification development, global sales and marketing, and new product introductions.

First given in the year 2000, the SPE Automotive Lifetime Achievement Award recognizes the technical achievements of individuals whose work—in research, design, and/or engineering, etc.—has led to significant integration of polymeric materials on passenger vehicles.

Referring to Deans as a “pillar of the automotive-composites community for decades” as well as a longtime cornerstone of the SPE Automotive Division, David Reed, GM-retired and also SPE Lifetime Achievement committee co-chair adds, “He’s someone who truly has dedicated his career to developing innovative automotive composites applications, like the first GMT composites bumper on the Chevrolet Corvette sports car—an application which, coincidentally, has been named our Hall of Fame award this year for its enduring industry impact.”

Deans is currently chief-marketing officer, and a co-founder and principal of Allied Composites Technologies as well as the owner of F.Deans & Associates, a Michigan-based enterprise. Among his accomplishments, Deans led development of the first unidirectional GMT composites for new-generation automotive bumper systems. The first application of this technology was a single 12-million lb application program with a Japanese automaker. Within three years, every Japanese OEM was using GMT composite for bumper beams.

Deans also managed the commercialization and use of next-generation direct-long-fiber thermoplastic (D-LFT) composites for passenger car underbody shields and underhood applications, as well as load floors for off-road vehicles and HVAC bases. He also helped develop and commercialize an automotive glass-forming process and introduced monolithic tempered privacy glass for SUVs.

Related Content

SPE Automotive Awards Applaud ‘Firsts’ and Emerging Technologies

The 51st annual SPE Automotive Innovation awards gave nods to several ‘firsts’ and added alternative vehicle systems category.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreMolder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

Read MoreDesign Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

(2).jpg;maxWidth=300;quality=90)