Three Themes at Fakuma Show

Servo hydraulics are becoming standard; servo pickers proliferate; water flow monitoring and control are new focus.

Some people call it the “mini K show.” The Fakuma exhibition in Friedrichshafen, Germany, used to be considered a local plastics trade fair for Germany machinery exhibitors to reach an audience in southern Germany, Austria, Switzerland, and the Czech Republic. But the show has grown continuously in importance, and Fakuma 2014 attracted nearly 46,000 visitors from 117 countries and 1772 exhibitors from 36 nations. It was my first time at Fakuma, where the press corps included editors from as far away as Hong Kong and Singapore.

It’s still predominantly an injection molding show, and that’s what I’ll focus on here. Among the new products introduced at Fakuma, three categories stood out because they were highlighted by multiple exhibitors. (In my business, if we see something three or more times, we’re tempted to call it a trend.)

1. Servo-hydraulics are the new standard. If you ask me, the future of hydraulics in injection molding—and I do think it has a future for a long while to come—is using pumps with variable-speed servo or frequency drives. When I offered that prediction, officials from Arburg agreed that “there is a clear trend toward servo hydraulics for energy savings and noise reduction.” Confirming that trend, several machine builders introduced presses with servo hydraulics standard instead of an option that used to cost around 10% additional but provided energy savings nearly equivalent to those of an all-electric machine. Examples:

• Wittmann Battenfeld (U.S. office in Torrington, Conn.) introduced the SmartPower series that will replace the conventional hydraulic HM series in sizes from 25 to 120 metric tons at no extra cost. They reportedly cost about 20% less than an all-electric for equivalent energy consumption.

• Sumitomo (SHI) Demag Plastics Machinery (U.S. office in Strongsville, Ohio) brought out the System Servo series. They do cost a bit more than standard Systec models, but Sumitomo says 60-70% of those machines are being sold with servo pumps anyway.

• KraussMaffei (U.S. office in Florence, Ky.) has revised and upgraded its CX Series in smaller sizes (35 to 160 m.t.) with servohydraulics now standard. A company official said, candidly, that there is no increase in list price, but discounts might be less than before.

• Haitian of China (U.S. representative is Absolute Haitian in Worcester, Mass.) has new smaller models of its servo-hydraulic, two-platen Jupiter II series, starting at 450 m.t.

• Engel (U.S. office in York, Pa.) still offers servo hydraulics as an option, but it’s one that 70% of its hydraulic machine customers purchase.

• Boy Machines (U.S. office in Exton, Pa.) already makes servo hydraulics standard on all its machines except its very smallest XS model (10 m.t.). Boy sees no further advantage in—and therefore does not offer—all-electrics.

2. Sprue pickers go servo. Servo-powered sprue pickers were a hot button at Fakuma, promising more speed and precision than pneumatics with lower energy consumption.

• Wittmann Battenfeld introduced the WS80 servo picker with a rotary axis and two linear axes. It’s designed to operate within the machine guards.

• KraussMaffei showed off its new SPX10 servo picker, also with a rotary axis and telescoping vertical arm. It operates within the machine envelope.

• Engelintroduced the servo-driven e-pic, which is distinctive for its horizontal traverse and toggle-type articulated vertical arm (similar to some Japanese designs I’ve seen) and a further telescoping action.

• While not new, Arburg (U.S. office in Newington, Conn.,) showed its two-year-old swiveling servo picker.

• Sepro (U.S. office in Pittsburgh) showed its S3 swiveling servo picker, which also appeared at Fakuma 2013 and K 2013.

• Boy operated its year-old swiveling sprue picker—a pneumatic model.

3. Mold cooling gets more attention. Injection machine suppliers are now addressing mold cooling as a process variable that has received far less attention than other sources of quality and productivity fluctuations.

• Engelintroduced the e-flomo water manifold that automatically monitors water pressure and temperature and adjusts water-flow valves to compensate for filter clogging and system pressure variations.

• Wittmann Battenfeld showed its new ultrasonic flow monitor for Tempro plus D series TCUs that now operates at higher temperatures (160-180 C) and measures flow rates down to 0.5 liter/min with ± 5% accuracy. Also new is the Flowcon plus water regulator, which controls either temperature or flow rate for each individual water circuit. It’s aimed particularly at non-heated water (up to 100 C) and measures flow in a noncontact manner from 1 to 15 l/min. Wittmann says more than half of its mold-temperature controllers are now sold with a flow-regulation device.

• KraussMaffei operated an all-electric AX machine with a flow-monitoring system integrated into the MC6 machine controller to document the mold heat balancing for quality records.

Related Content

Next-Generation All-Electric and Vertical Injection Molding Machines

Sodick Plustech’s VR-G and MS-G2 Series both utilize the company’s proprietary V-Line technology, separating plasticizing and injection functions, and have upgraded displays, energy efficiency, response time and more.

Read MoreCustom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreIPEX Opens Injection Molding Facility in North Carolina

The pipe and fittings manufacturer’s new 200,000-square-foot facility represents a $200 million investment and will create 150 jobs.

Read MoreCompact Hybrid Injection Molding Machine Launched

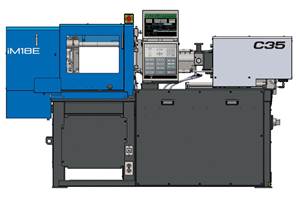

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

(2).jpg;maxWidth=300;quality=90)