Joint Project Will Demonstrate Recycling Polyamide 66 Using Microwave Technology

Materials producer Asahi Kasei and recycling technology developer Microwave Chemical announced a joint chemical recycling project.

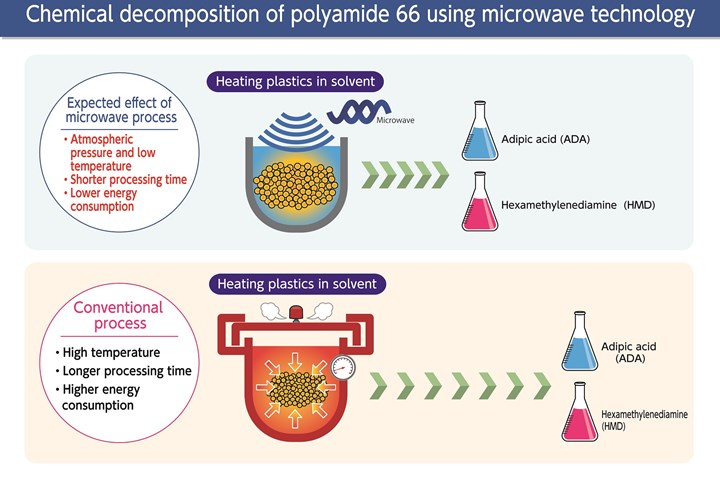

Asahi Kasei and Microwave Chemical have launched a joint demonstration project with the objective of commercializing a chemical recycling process for polyamide 66 using microwave technology. The process utilizes microwaves to depolymerize PA66 and directly obtain hexamethylenediamine and adipic acid, the six-carbon monomers it is named for. The monomers can then be used to manufacture new PA66. In the demonstration, scraps from manufacturing and post-use waste material of PA66 for airbags and automobile parts are depolymerized.

The use of microwaves is expected to reduce energy needed for depolymerization.

Photo Credit: Microwave Chemical

Since 2021, laboratory scale studies have confirmed the high-yield depolymerization of PA66 using microwaves, as well as subsequent processes for separation and purification of the monomer products. Microwave’s proprietary PlaWave technology operates at lower temperatures and has lower energy requirements than conventional processes for depolymerization of PA66.

Asahi Kasei currently produces Leona 66, an engineered PA66, from fossil fuel-derived hexamethylenediamine and adipic acid, with automotive and electronics applications.

Benchtop demonstration trials are planned for 2024, with a decision on commercialization expected by 2025. Microwave Chemical is also working to expand the types of materials its PlaWave technology can be used to chemically recycle, including PMMA, PU foam, automotive shredder residue, and others.

Related Content

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

-

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.