Automation: New Hardware & Software for Low-Cost Robots

igus offers a new linear seventh axis, free downloadable control software, and a new range of modular components.

A new linear seventh axis, free downloadable control software, and a new range of modular components are available for the Low-Cost Automation platform from igus (see February Close-Up on robots at K 2019). The company’s four- and five-axis robolink DP articulated-arm robots already have a sixth rotational axis available. Now, igus has added another modular option, a linear seventh axis (horizontal or vertical), which can expand the robot’s working volume fourfold. What’s more, the new linear axis—which makes use of igus’s drylin linear guides—is also available for other robot brands, such as Universal Robots.

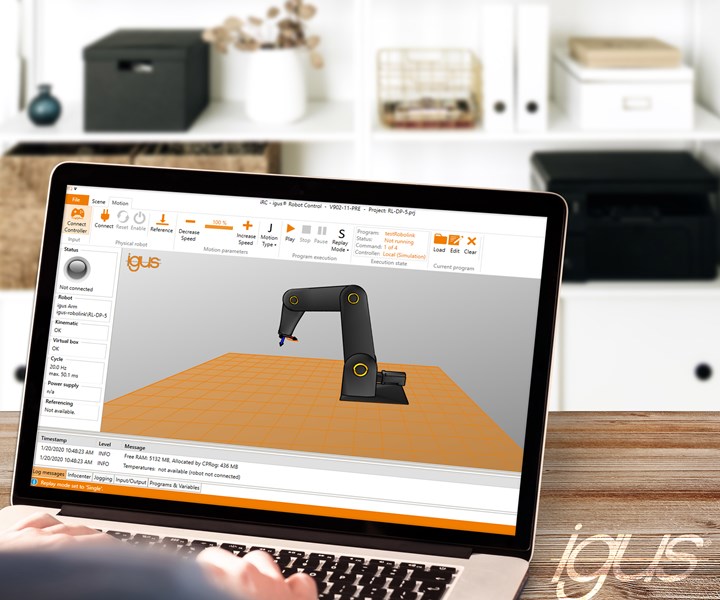

Software for lead-through programming via “digital twin” on screen is downloadable for free.

Second, igus introduced new easy-to-use programming software for its entire line of robots—articulated arm, delta, and linear types. The software is downloadable for free. It allows for simple “lead-through teach” programming of a “digital twin” or simulated robot on-screen (photo). The user manually moves the robot through the desired positions, using a mouse or a finger on a touchscreen. Virtual safety boxes can be specified to prevent the robot from colliding with other equipment. The program can then be applied to an actual robot. It also can connect to a higher level control system via interface communication, wit digital I/O or Ethernet protocol using an IP address. igus calls this offering “try before you buy” because you can try out the simulated control before buying actual hardware.

Speaking of hardware, igus has launched the RBTX online platform (rbtx.com) with a catalog of compatible modular components for robots from a range of suppliers. Such components currently include grippers/end effectors, vision systems, pneumatics, control hardware and software, and auxiliaries. These products currently come from igus and five other partners; 10 more are due to come on board this year with 70 to 80 new products.

Related Content

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.