Clamps Allow Faster Mold Changes

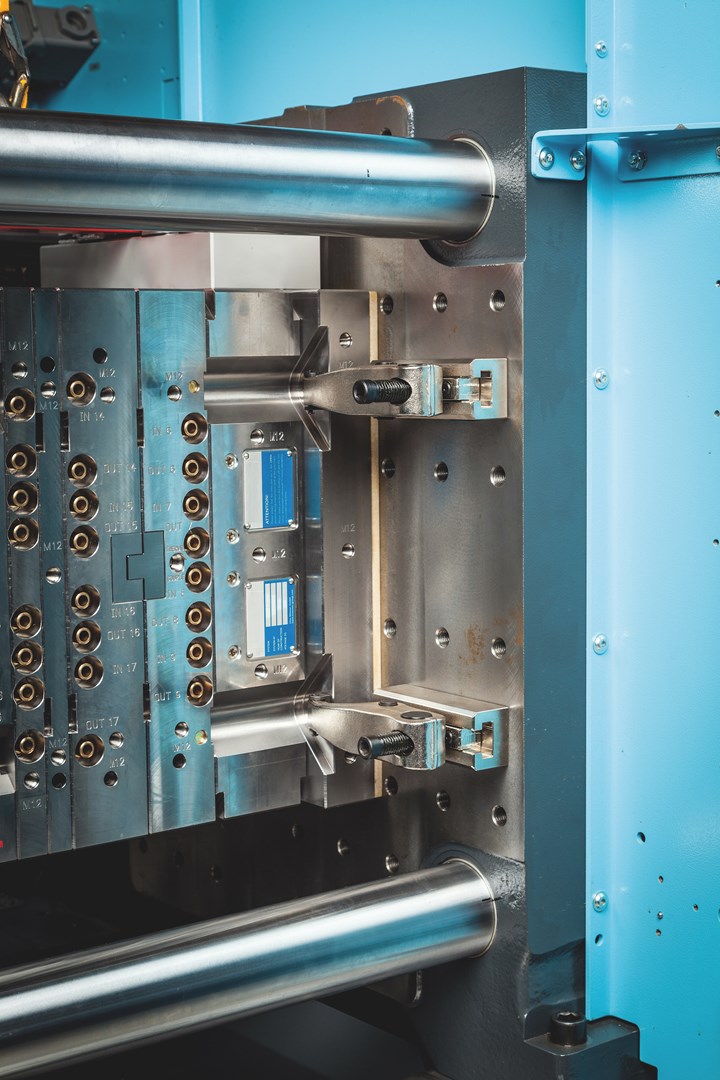

Mouldpro says its Power Sliding Clamp can accommodate a range of different mold back-plate sizes and thicknesses.

Mouldpro ApS (Ballerup, Denmark), which is distributed in North America by Globeius, has introduced the Power Sliding Clamp for faster mold changes. The clamps can adapt to a range of different mold back-plate sizes and thicknesses, with four clamp sizes are available. The sizes include the SC-100 (3500 lb clamp force), SC-200 (4400 lb clamp force), SC-250 (5500 lb clamp force), and the SC-300 (12,100 lb clamp force).

These clamps can be used in threaded or t-slot platens and are designed to slide by virtue of an integral t-slot. This feature allows it to be fixed in the best position for clamping, according to Mouldpro, with an adjustable bolt suited for different clamp heights. Able to work with Quick Mold Change (QMC) setups, these clamps feature a nickel-plated finish for corrosion and wear resistance. Globeius has the clamps in stock and ready for delivery throughout North America from its warehouse in Miami.

Mouldpro has introduced the Power Sliding Clamp with four sizes available.

Photo Credit: Globeius

Related Content

-

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

-

Tunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

(2).jpg;maxWidth=300;quality=90)