Dual-Mold Structural-Foam Machine for Pallets

Wilmington’s new dual-mold press lowers pallet cost 40% compared with a single mold.

Wilmington Machinery has launched its newest low-pressure structural-foam machine for pallets, what it calls the “lowest-cost dual-mold pallet machine on the market worldwide.” Compared with a single-mold pallet machine, conversion cost with the new Lumina Palleteer Model PM-3C is said to be around 40% lower per pallet.

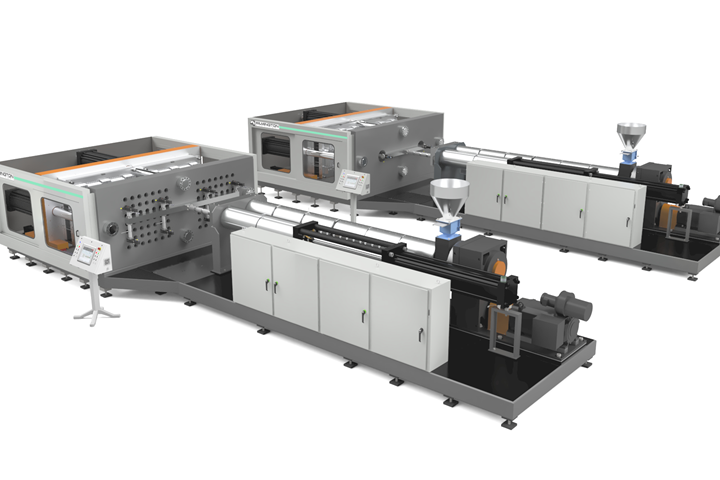

New Lumina Palleteer PM-3 press outfitted for hot-runner molding (rear) and external multinozzle structural foam.

The new machine has considerably enhanced specs relative to the existing Lumina Palleteer PM-3. The PM-3C comes with a 675-ton press capable of molding two pallets side by side, each measuring up to 48 × 52 in. and weighing up to 40 lb. Its two-stage injection unit—with electric-driven extruder and bimetallic barrels—can process up to 2400 lb/hr of HDPE, sufficient to produce up to 80 pallets/hr and over 600,000/yr. Like other machines in the series, it can process up to 100% recycled material, even in flake form.

The machine is available with either Allen-Bradley or Beckhoff PLC control and outfitted for hot-runner molds or “classic” external multi-nozzle structural-foam setup (both are shown in the accompanying photo). Either method is capable of gas-assist or gas counterpressure molding techniques. The system is also offered as just a machine plus molds or as a fully integrated pallet production system with robotics, resin blending/loading, mold cooling and other accessories.

Related Content

-

Absolute Haitian Brings Next Generation of Presses to Orlando

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

-

IPEX Opens Injection Molding Facility in North Carolina

The pipe and fittings manufacturer’s new 200,000-square-foot facility represents a $200 million investment and will create 150 jobs.

-

All-Electric Press Gets U.S. Debut

NPE2024: For the first time, Arburg is making a global premier of a machine outside Germany with the new Allrounder 720 E Golden Electric among its 13 exhibits — seven in its own booth — in Orlando.