Enhanced Hot Runner Manifold Leak Detection

The Advanced Plastic Leak Detection capabilities on Mold-Masters’ TempMaster hot runner temperature controllers now include thermal identification via thermocouples.

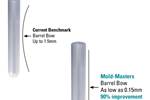

Mold-Masters announced an enhancement to the Advanced Plastic Leak Detection capabilities on its TempMaster hot runner temperature controllers, adding thermal analysis to detect plastic leakage within the manifold pocket.

To enable this feature, thermocouples are installed on the manifold in various locations. These sensors are dedicated to monitoring and detecting manifold leakage. The size of the manifold will dictate how many detection thermocouples are necessary, and the position of each thermocouple will determine how quickly leakage is detected. Mold-Masters says that during internal testing of the new feature, leakages were discovered before any damage had occurred.

Manifold Leakage Detection is an optional feature available now with all Mold-Masters TempMaster M2+ and M3 hot runner temperature controllers. The company’s original Plastic Leak Detection feature, which detects plastic leakage within the nozzle pocket, is included with all M2+ and M3 controllers as standard.

The Advanced Leak Detection package for Mold-Masters’ TempMaster hot runner temperature controls thermally identifies leaks.

Photo Credit: Mold-Masters

Related Content

-

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.