High-Efficiency Stabilizer for Aliphatic Nylons

Brüggemann’s Bruggolen TP-H1804 designed for use at continuous temperatures between 320°F-to-374°F

A new heat stabilizer masterbatch for aliphatic nylons is said to provide longer service life at high temperatures. Bruggolen TP-H1804 from Brüggemann is designed for use at continuous service temperatures between 320°F and 374°F. It complements Bruggolen TP-H1805 which stabilizes reinforced nylons at temperatures above 392°F. Supplied in granular form, this additive concentrate can be dosed very precisely, and thus in a very targeted manner.

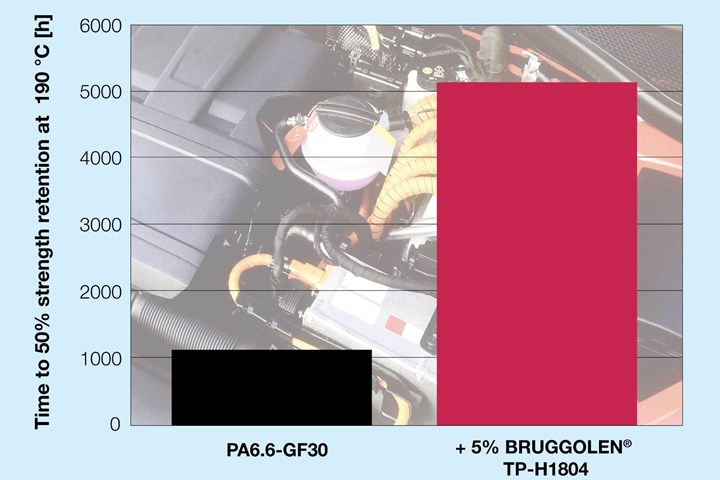

As “best in class”, according to the company, Bruggolen TP-H1804 significantly outperforms previously available copper salt-based stabilizers in terms of maintaining mechanical properties. For example, the tensile strength of a glass fiber reinforced nylon 66 with the addition of 5% is still over 50% of the initial value after 5,000 hours of heat ageing at 374°F; the un-stabilized material barely reaches this limit at 1,000 hours. At 338°F, thanks to its outstanding efficiency, even 2.4% is sufficient to exceed the 5,000-hour mark. As such, Bruggolen TP-H1804 is a product which, through its flexible dosing capability, allows molded component service life to be adapted to expected thermal loads.

Related Content

-

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

-

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

-

K 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

(2).jpg;maxWidth=300;quality=90)