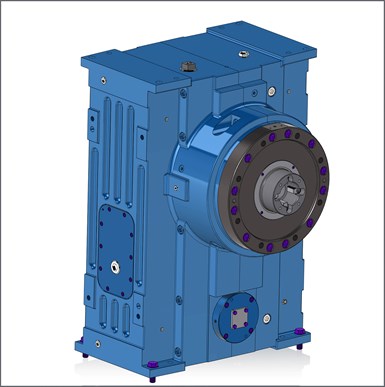

Next-Generation Gear Reducer is Sleek, Robust

Can accommodate a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures.

Davis-Standard’s next-generation gear reducer features a sleek new design and represents a commitment to customer feedback, field experience, and technical engineering while building upon the robust performance synonymous with Davis-Standard gear reducers. The new reducer fulfills a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures. It can also accommodate the DS Activ-Check system, Davis-Standard’s Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts.

The new gear reducer is available in five different dimensions and capacities for extruders ranging from 2 in. (50 mm) to 6.5 in. (165mm). Reported advantages include:

Horizontal and vertical orientations : The horizontal orientation is said to be a good fit for belt-driven machines and/or low centerlines. This allows for a range of belt drives, versatile feedscrew timing, and adaptability to direct-coupled drives. The vertical housing arrangement is designed for direct-coupled and narrow footprint machines. It allows for tight positioning of extruders used in multilayer processes.

Image: Davis-Standard

Cooling and lubrication: There are two cooling and lubrication options based on housing style and customer requirements. These include oil bath lubrication and partial immersion/forced lubrication.

Gears and roller bearings: Case-hardened precision ground helical gearing is available in a wide range of gear reduction ratios to suit process requirements. New to this reducer series are spherical roller thrust bearings which absorb the axial process load and provide a self-centering, compact design with superior low-friction characteristics.

Radial shaft seals : All reducers are fitted with high-quality, spring-loaded radial shaft seals to contain lubrication oil and exclude contaminants.

Felt excluder: A felt ring excluder has been added to the front output shaft to protect the shaft and seal from abrasion and extend seal life.

Housing design: Durable cast iron construction provides quiet operation and minimal vibration. Large inspection ports simplify viewing of gear tooth condition, and a non-vented, bullet-type oil sight check eliminates the potential for leakage. Large oil fill ports allow for easier filling, while a low point drain port enables complete draining. A front thrust shaft cover completely encloses the reducer housing, allowing for more precision seal-to-shaft alignment.

Davis-Standard says the new gear case can be retrofit to older extruders in some cases.

Related Content

-

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

-

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

-

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators