Tooling: Hose Provides Flexible Cooling

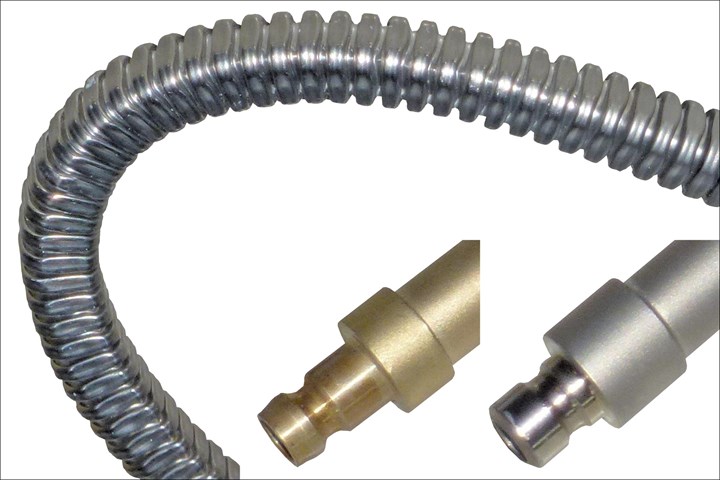

Hasco’s TempFlex Z976/ and Z977/ metal-braided hose provides assembly, interchangeability, and adaptability to any groove pattern.

Hasco says its TempFlex Z976/ and Z977/ can be outfitted on existing molds with inadequate cooling performance to provide cooling optimization, bringing temperature control to mold or spacer plates via simultaneous conformal cooling. Complex deep-hole bores and high-pressure losses due to 90° deflections can be eliminated.

The flexible metal-braided hose allows flow rates to remain the same, while high temperature resistance is also guaranteed. The square hose cross-section offers optimum heat transfer to all mold plates. Corrosion in the cooling channels can also be eliminated.

The TempFlex Z976/ is available in diameters of 9 and 13 mm with three different lengths and a metric connection. The Z977/ comes in 9-mm diameter as per the U.S. Standard. Other lengths can be supplied as custom sizes. Because there is no deep-hole boring and plugging, Hasco says using the new TempFlex for manufacturing mold plates can lead to a considerable cost reduction.

The flexible metal-braided hose allows flow rates to remain the same, while high temperature resistance is also guaranteed.

Related Content

-

Wisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

-

Captive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

-

High-Temperature, Low-Flow Indicator for Mold-Cooling Applications

Burger & Brown Engineering has released a new high-temperature low-flow indicator to monitor flow inside critical, restricted cooling paths such as those with bubblers or baffles.

(2).jpg;maxWidth=300;quality=90)