Simulation Software Offers More Insights into Coextrusion, Layer Incapsulation

NPE2024: Compuplast to also debut simulation tools for blow molding and thermoforming.

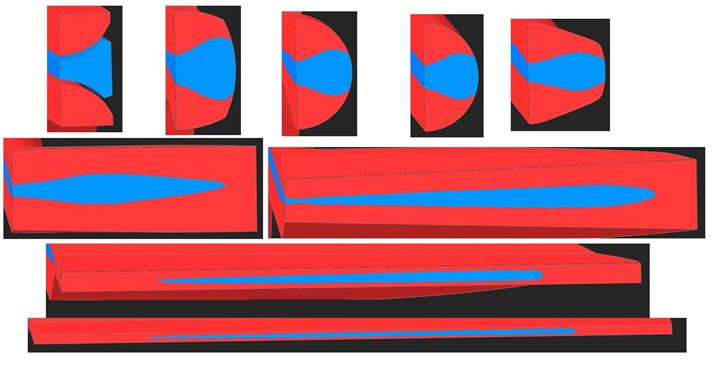

Compuplast North America is showcasing the latest releases of the Virtual Extrusion Laboratory 3D Module, which can now simulate coextrusion and show layer encapsulation. The accompanying image shows cuts in the flow field from the merge point to the die exit. Note how the middle layer deforms as it flows along and disappears in the center of the web (half symmetry analysis). Compuplast has also added the capability to predict the deformed shape of a profile in 3D.

Compuplast is also showing simulation products from Accuform. These include the fully 3D versions of its T-SIM (Thermoforming) and B-SIM (Blow Molding) simulation software. Prior versions used a “Mid-Plane” approximation of the polymer sheet or parison with 2D, triangular elements. The new 3D versions use layers of hexahedral (brick), elements to define the sheet. Compuplast is Accuform’s representative in North America.

Related Content

-

Why Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

-

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

-

Specialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.