Infrastructure May Prove Big Landing Spot for Recycled Plastics

As the government funds infrastructure improvements, a hot topic at NPE2024 – exploration of the role recycled plastics can play in upcoming projects, particularly road development.

For decades, plastics have proven themselves as viable materials in building and construction. Industry veterans may recall the concept house GE Plastics (now SABIC) built in Pittsfield, Massachusetts, in 1989 to demonstrate possible applications for plastics in homes.

“The plastics industry ... is in a prime position to contribute to our nation’s infrastructure needs. From improved recovery facilities to uses in pavements and pipes, plastics can play a role.”

– The Plastics Industry Association, Producer of NPE2024

This model suburban home showed liquid crystal plastic windows that could change from transparent to opaque at the flick of a switch. Cutaway cross sections showed possible plastic construction concepts, including modular plumbing panels and snap-on plastic wall sections.

Today, of course, plastics is a staple in construction, used in plumbing, decks, windows, siding, fencing and a lot more.

Lurking, though, is a new opportunity in which two burgeoning opportunities converge: infrastructure development and recycled plastics. Passed in 2021, The Infrastructure Investment and Jobs Act earmarks $550 billion over fiscal years 2022 through 2026 in new federal investment in infrastructure projects that include roads, bridges and mass transit, water infrastructure and broadband.

As the Plastics Industry Association points out, “The plastics industry ... is in a prime position to contribute to our nation’s infrastructure needs. From improved recovery facilities to uses in pavements and pipes, plastics can play a role. The infrastructure policies we advocate for create jobs, protect the environment and improve our daily lives.”

VISIT: The NPE2024 Recycling & Sustainability Zone

More on pavements: Research is underway to determine whether recycled plastics can play a role in some upcoming infrastructure projects, particularly road development. According to an article in FastCompany.com, multiple states are testing whether asphalt roads mixed with discarded bags, bottles and other reclaim can make pavement last longer, save money and reduce the amount of waste that ends up in landfills. The article noted that in Missouri a pilot program is being conducted on a busy highway made of asphalt mixed with pelletizing bottle flake, and that California is testing a road made of a mixture of asphalt and 10% scrap from printer cartridges.

Meantime, in a white paper commissioned by the National Academies of Sciences, Engineering, and Medicine (NASEM), Stanford University engineers Michael Lepech and Zhiye Li studied the current status, challenges and needs of recycling plastics in a circular economy, and examined the long-term durability and environmental costs of doing so for use in infrastructure.

Notes Li, in an article that appeared on the Stanford University website, “Upcycling of recycled plastics in infrastructure sets an example of creating value by creating demand. The recycled plastic-blended construction material needs to achieve certain performance requirements and maintain lower environmental impacts than conventional construction materials. Our paper shows that for a use case that has a longer life span — such as certain blended plastic composite building panels or asphalt pavement — the needed quality and sustainability requirements are more achievable. Upcycling plastic waste in infrastructure has attracted increasing interest because it creates something of high value for which there is large potential demand.”

Last year, meantime, Recycling Today reported that the National Academies of Sciences, Engineering and Medicine issued a report in which it recommended how the Environmental Protection Agency and the Department of Transportation join forces to promote and sustain a coordinated government response to end-of-life plastics in the U.S. that includes assessments of using recycled plastics in infrastructure.

Related Content

Nova Makes Senior Leadership Changes

The company’s aim is to bolster sustainability ambitions

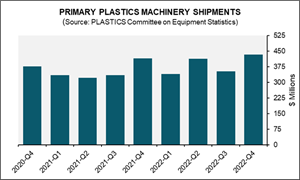

Read MorePlastics Machinery Shipments Rose in 2022’s Final Quarter

The Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES) reported that injection molding and extrusion machinery shipments totaled $432.7 million in Q4.

Read MoreArtificial Intelligence Enables Smarter Sourcing

Westfall Technik has adopted Arkestro’s predictive procurement software to wring savings and more reliable deliveries from a historically challenging supply chain.

Read MoreRecord Reshoring Rates in 2022

Reshoring and foreign direct investment (FDI) in the third quarter marked their highest ever level, eclipsing the previous record set in the second quarter of 2022.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More