Recycling News at K 2013

Close Up: Recycling

New developments combine recycling and compounding in one step. Plenty of news at K in size reduction and de-labeling.

New technology unveiled at K 2013 is aimed at giving recyclers more capabilities, such as the ability to add compounding to their service mix. This was evident in at least three exhibits.

Erema (U.S. office in Ipswich, Mass.) has dubbed its new system “upcycling.” Its official designation is Corema, and it combines recycling and compounding in a single processing step. The combination of these two processes translates into forward integration for the recycler or reverse integration for the compounder. Erema has teamed with Coperion (U.S. operation in Ramsey, N.J.) for twin-screw compounding machinery.

Post-consumer material is fed into the Erema cutter/compactor, where it is cut, homogenized, heated, dried, and buffered. The preheated material is plasticated in the tangentially connected single-screw extruder and cleaned in an automatic, self-cleaning filter. The prepared melt then goes directly to the Coperion corotating twin-screw extruder, where fillers and other additives are incorporated. Systems are available in throughput from 660 to 8000 lb/hr.

The front end of the tandem system utilizes another new product Erema displayed at K, called Intarema. In Erema’s standard cutter/compactor, which is mounted at the extruder feedthroat, the cutting disk rotated counterclockwise. As a result, material was typically “chasing” the extruder, Erema officials explained. In the new system, the cutting disk spins clockwise to fill the flights of the recycling extruder more effectively, resulting in substantially higher throughput.

A relationship similar to that of Erema and Coperion was announced by NGR Recycling Machines (U.S. office in Norcross, Ga.) and twin-screw supplier Leistritz (U.S. operation in Somerville, N.J.). NGR also showed a new touch-panel control system for its recycling system that offers significantly more internal storage than previous versions, which enables it to display more information at the point where the operators need it. On NGR recycling systems, cleaning of shredder knife-holders is now possible through adjusting the mounting screws. Dust outlets are now equipped with dust boxes or bags, which can be cleaned during operation.

Starlinger & Co. of Austria (represented by American Starlinger-Sahm, Inc., Greenville, S.C.) showed its new C-VAC degassing module for recycling heavily contaminated or highly printed scrap. At the show, it was deployed on a recoSTAR universal recycling line.

The C-VAC module is an integrated but independent single-screw extrusion module that can be added to every Starlinger recoSTAR recycling extruder. Teaming the C-VAC with a separate single-screw degassing extruder improves venting performance and recycling.

Compounding takes place in the degassing extruder after the melt filter. As this extruder works independently of the melt extruder, screw design and screw speed can be different to optimize compounding. The system is said to be particularly advantageous for incorporating glass fiber because single-screw extrusion minimizes glass breakage.

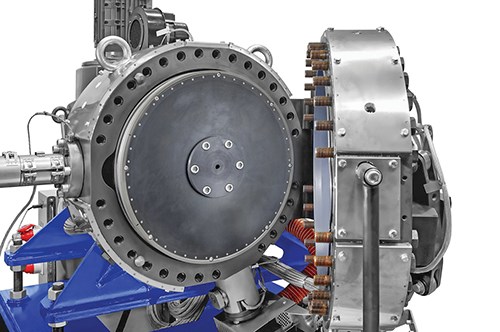

Meantime, efactor LLC 3 (U.S. office in Charlotte, N.C.) showed its integrated recycling-compounding solution in a package that included shredders by Weima Maschinenbau (U.S. office in Ft. Mill, S.C.), as well as dry cleaning, corotating conical twin-screw compounding, and melt-filtration technology from Austria’s MAS. MAS’s Continuous Disk Filtration System is available in four sizes. The newly introduced and largest system, the CDF 500‐D, is designed with two filter units in parallel, which have a diameter of 510 mm. The “twin” configuration makes the filter easy and flexible to handle, both during cleaning and maintenance and during transfers between different extrusion lines when required.

SCRAP-EATING SHREDDERS

Weima introduced a single-shaft shredder, the WLK 800, with a “pipe spacer” hopper design that prevents material from bridging inside the hopper. The feed motion of the ram is load-dependent, which prevents overloading. This model also features a swivel-screen basket that makes the rotor more accessible for preventive maintenance. The WLK 800’s counter knives can be rotated, extending their life. Applications include purgings, pipe, automotive parts, and bottles.

Weima’s other new shredder, the Spider 1500 H comes with a newly developed hydraulic drive by Hägglunds-Bosch Rexroth. This drive enhances energy efficiency through lower drive power. There are also no power surges when the rotation reverses. The new drive is set up in a compact way that saves space and eases maintainenance.

The V-ECO 1700 shredder from Vecoplan AG (U.S. office in Archdale, N.C) offers a high-performance cutting rotor with optimized tool geometries, frequency-controlled drive that is insensitive to tramp material, optimized adjustment of the cutting gap to increase performance and reduce wear on cutters, easy removal of tramp material, and simple and ergonomic counter-knife changes.

New from Rapid Granulator (U.S. office in Cranberry Township, Pa.) is the Raptor Series of shredders. They have an “open-hearted” design that gives access to all core components for cleaning, service, and maintenance in 70 sec. The line initially consists of five models, all of them modular to allow tailoring for specific applications. The first models are expected to be available in the first quarter.

In other news, Germany’s S+S Separation and Sorting Technology GmbH (U.S. office in Bartlett, Ill.) launched the Rapid Pro Sense metal separator. Using High Resolution Frequency technology, the modular unit reportedly features extremely high scanning sensitivity for all metals.

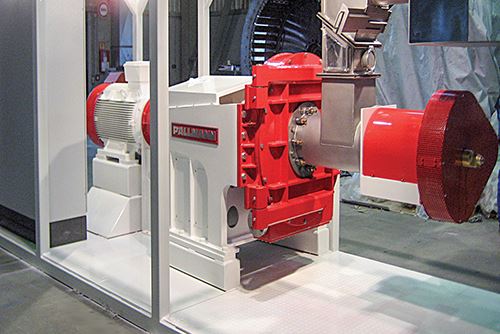

There were also some new developments for label removal. Pallmann Group (U.S. office in Clifton, N.J.) showed off the HydroFiner, a new way of removing sticky labels from packaging film at rates up to 4000 lb/hr. The conventional way of recycling such waste is to granulate it and reprocess it in an extruder. That requires a lot of melt filtration and frequent changes of melt filters. It may be possible to remove the labels by washing the packaging, but that usually requires hot water, which consumes energy; or solvents, which introduce another cost. Instead, the HydroFiner uses hydromechanical action to remove sticky paper label laminates. Waste is rubbed intensively between two surfaces, using a small amount of water. The material rubs mostly against itself, rather than the metal surfaces of the machine. The labels and the glue are separated and removed, and the packaging is reduced to flakes.

The process is based on two discs—a rotor and a stator—with material being fed to the center via an auger and then moving to the outside through pairs of intermeshing teeth. The time the material is kept between the discs can be adjusted by changing the speed of the rotor and by adjusting the amount of water. The water is injected at three locations and is recycled back into the system.

A new delabeler from Italy’s Sorema removes glued sleeve labels from PET bottles. Three models are available in capacities from 1110 to 15,000 lb/hr. They are said to offer label-separation rates of up to 98.5% with very little loss of bottle necks. The delabeler can also be used as a dry pretreatment station for mixed bottles or rigid packaging when teamed with an aerodynamic separator.

U.K.-based Bühler Group (U.S. headquarters in Plymouth, Minn.) launched a fully integrated Optical Sorting Station, said to be the first to bring together plant engineering, optical sorting technology, pneumatic conveyors, preconditioners, and auxiliary equipment. This means that processors no longer need to source separate elements from multiple suppliers.

For flake processing, an optical sorting station has a purifying, refining, sizing and grading stage, which can include one or more optical sorters. These are linked by auxiliary equipment to convey the product between stages and, if required, to reintroduce it into the system for resorting. Flakes can be fed into one end of the station and collected at the other end, ready for bagging or further processing.

Related Content

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreSD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

Read MoreReversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More