The Then and Now of NPE

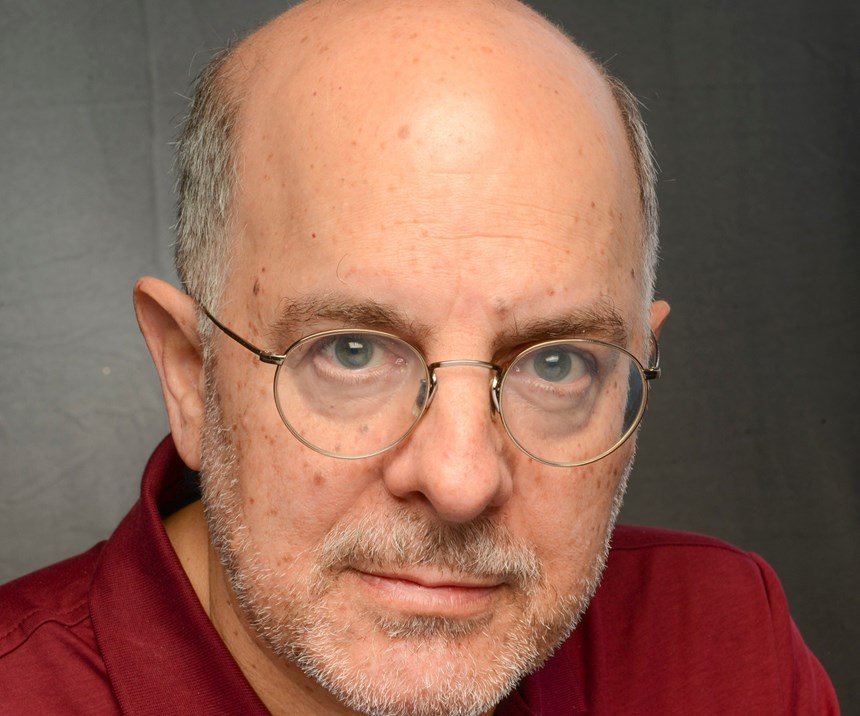

Matt Naitove, executive editor of Plastics Technology, shares the experiences and insights he’s gained from attending 15 NPEs since 1973.

NPE has been a plastics industry “must-attend” event for more than 70 years. Participants representing more than 20,000 companies from all over the world attend. But how has it grown and evolved over the years?

Matt Naitove, executive editor of Plastics Technology, has some pretty good insight. Naitove began attending the show in 1973 as a cub reporter and this is his 16th NPE. So, it’s fair to say he knows the ropes.

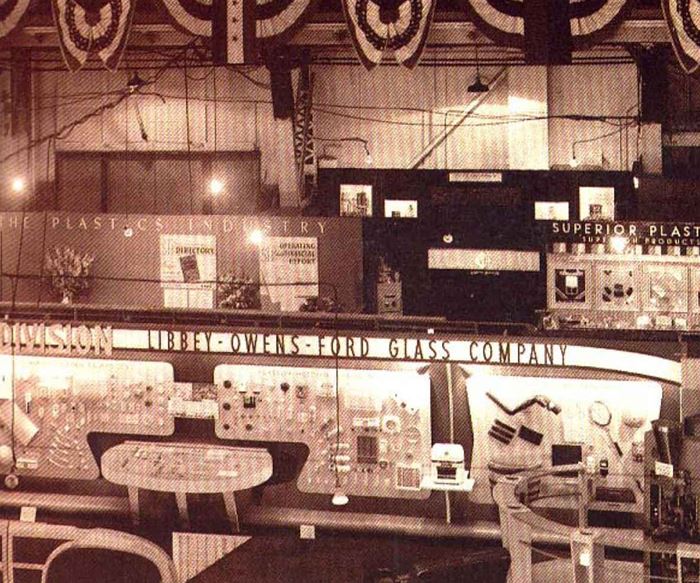

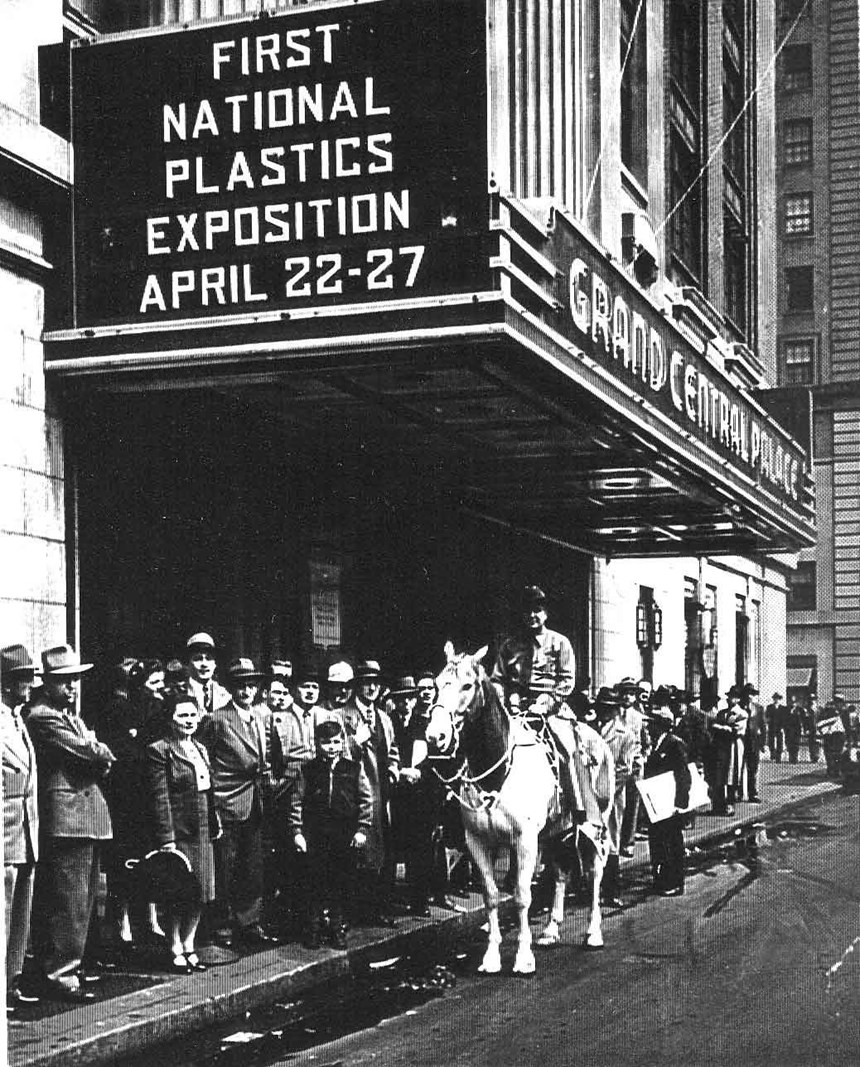

According to Naitove, the very first NPE was in New York City in 1946. There were 164 exhibitors–most of them in 10 x 10 booths–and the show occupied one 24,600 ft2 exhibit hall. Reportedly, 87,000 people showed up. Why so many? The first NPE was open to the general public.

“The place was mobbed, and the fire marshal had to shut the doors,” says Naitove.

When Naitove started coming to NPE in the 1970s, attendance was around 40,000 and has grown to 65,000. There are now more than 2000 exhibitors and the show occupies 1.1 million ft2–a far cry from those early days of the 10 x 10 booths.

So, what was big at NPE in the 1970s?

“Solid state controls, if you can imagine,” says Naitove, “I’m amused to look back and see solid state controls on machines was a news item–I mean as opposed to vacuum tubes. And I remember people touting having a microprocessor on their machines. Now, that’s like saying ‘my machine runs on electricity!’”

“You’ll see a group of people at the show talking about the same thing and the next thing you know, it’s a trend. I guarantee you’re going to find something you didn’t expect–something you weren’t looking for.”

Technology isn’t the only thing that’s changed. Business has become increasingly more global. According to Naitove, the first NPE was composed entirely of U.S. exhibitors. Today, international companies make up at least 40% of exhibitors. “That’s a big change in the industry,” says Naitove, “A lot of consolidation and the fact is that the machine technology for plastics largely comes from abroad today.”

Along with new technologies and new markets come new trends. In the 1980s it was robots. In ‘88, quick mold change systems. In the last decade, medical applications have become a big trend.

“Back then it wasn’t unusual to see a machine standing on the carpet cranking out some parts,” recalls Naitove, “Today companies are promoting what you would call a work cell. There’s a collection of equipment upstream and downstream, automated feeding and blending equipment, a robot’s putting a part on a conveyor or feeding an inspection, assembly or decorating operation–a whole manufacturing system.”

The way exhibitors showcase their products and services has also evolved.

“There’s more wow-factor and showmanship today,” says Naitove, “Some of it is more entertainment-oriented: Wittmann-Battenfeld is famous for showing robots playing basketball and at the last NPE show Star Automation played miniature golf with robots.”

Technology advancements and trends continue to come down the pipeline. Just how much will NPE grow? Looking back at 1946 it sounds like 87,000 is still the number to beat! One thing’s for sure, the plastics industry will continue to grow and evolve. And NPE continues to evolve right along with it.

“A show like this becomes a big pool of information you can draw on for the next few years,” says Naitove. “You’ll see a group of people at the show talking about the same thing and the next thing you know, it’s a trend. I guarantee you’re going to find something you didn’t expect–something you weren’t looking for.”

Related Content

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreInfrastructure May Prove Big Landing Spot for Recycled Plastics

As the government funds infrastructure improvements, a hot topic at NPE2024 – exploration of the role recycled plastics can play in upcoming projects, particularly road development.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreHonoring Excellence at NPE 2024: Plastics Hall of Fame

Yesterday, the Plastics Hall of Fame celebrated a legacy of innovation and vision for the plastics sector with 17 new members. Discover how these pioneers have helped shape the future of plastics.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;width=70;height=70;mode=crop)