Color-Measurement for Extrusion, Molding

System helps processors control the cost of quality due to color variations, using real-time color data for QC analytics and color optimization.

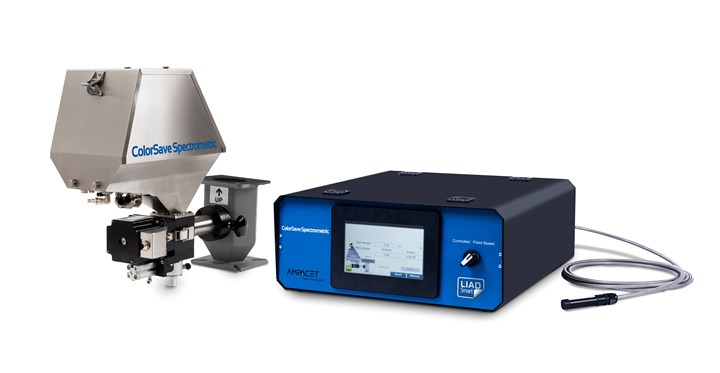

Spectro 4.0 Smart Technologies from Ampacet LIAD is a new line of innovative continuous in-line QC solutions for color management.

The first of two products in the lineup is Spectro 4.0 Smart, a color- measurement system for extrusion and molding processors that helps them control the cost of quality due to color variations, using real-time color data for QC analytics and color optimization.

Spectro 4.0 Smart reportedly ensures every part meets color specifications through Industry 4.0 advances such as optical real-time and in-line monitoring, using a fiber optic probe that can be positioned within the production line. The system automatically adjusts for color variations even when using PCR and regrind materials and operates within tight color tolerances to reduce color usage and costs.

Spectro 4.0 Smart operates in real time on the production line to provide immediate and actionable color management. The system’s differential spectrophotometer compares the color of the new product to a reference color in real time. Multiple and interchangeable probes will be available for simultaneous multi-point measurement of haze, opacity, reflection and transmission and to allow selection from differential or absolute testing modes.

The in-line system, designed to work in harsh industrial environments, also includes automatic built-in calibration against drifts and ambient illumination. A cloud capability is available for off-site tracking and alerts.

Photo: Ampacet LIAD

Spectro 4.0 Smart connects with another product in the Spectro 4.0 lineup, Ampacet LIAD’s patented SpectroMetric system, a major advance in color accuracy technology. SpectroMetric integrates all of the benefits of the Spectro 4.0 in-line spectrometer with the SpectroMetric in-line continuous color correction system. It incorporates the ColorSave 1000 masterbatch feeder to adjust masterbatch dosing automatically, in real time, ensuring color consistency.

SpectroMetric runs on L*a*b* specifications, not on set LDRs, and continually monitors for the lowest possible colorant usage rates to maintain correct color specifications—even when running PCR or regrind. The result is a system that seamlessly feeds, tests, monitors and corrects without human intervention, supporting lights-out operation.

Other benefits obtained when using Spectro 4.0 QC solutions include color production line standardization in multiple facilities regardless of manufacturing location; minimal maintenance, elimination of lot-to-lot variations in color commonly associated with increased use of PCR or regrind and operation within extremely tight tolerances, enabling prediction and maintenance of lower masterbatch levels.

Related Content

-

Exact Metrology Now Distributor of HandsOnMetrology.com

The new digital format was set up to share the benefits of 3D metrology with a global community.

-

Datacolor Launches Annual Subscription Payment Program for Color Management Software

The subscription plan is available for Datacolor Tools color QC application for plastics and other software products.

-

X-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.