Drying

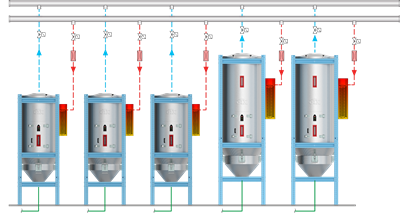

Resin Drying Hoppers Offer More Energy Efficiency, Durability and Cleanability

NPE2024: Drying hoppers provide improved energy efficiency and a durable textured metal exterior finish. Thicker insulation provides a cooler working environment, while polished stainless steel interiors resist material entrapment, and make cleanouts and changeovers faster.

Read MoreMore Efficient, Precise Blending and Drying Solutions

NPE2024: ABS debuts new blending, drying and repelletizing products in Orlando, plus a new color analyzer.

Read MoreRelaunched Chillers, Blenders, Dryers

NPE2024: New auxiliaries from AEC include chiller that meets new standards for refrigerants.

Read MoreCompressed-Air Dryer for Low Throughputs

NPE2024: Line has output range from 1 to 15 pounds.

Read MoreCompact, Mobile Dryer Has Unique Conveying Capabilities

NPE2024: Mobile dryer includes closed-loop conveying to minimize the use of ambient air for resin movement.

Read MoreSoftware Helps Processors Make Better Business Decisions

NPE2024: Tracker Monitoring and Reporting Software supports ISO reporting and material validation, including PCR usage and equipment status monitoring.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

WatchCaptive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

Watch