Know-How

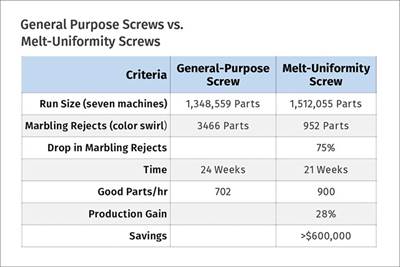

Improve Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreHow to Design Three-Plate Molds – Part 3

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

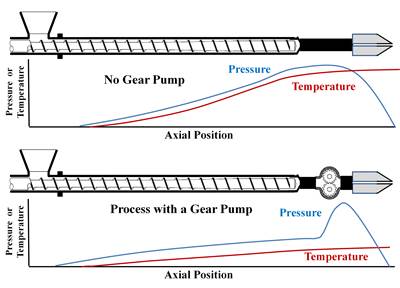

Read MoreIs a Gear Pump Right for Your Single-Screw Operation

As with everything else, there are pros and cons, but more of the former. They provide processors higher rates while decreasing the temperature of the extrudate while enabling downgauging.

Read MoreThe Experience Curve and Well-Trained Process Technicians

Pairing external big picture training with internal job-specific instruction can help your process technicians meet quality expectations as well as production targets.

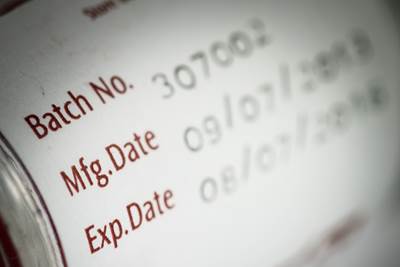

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 2

For the vast majority of thermoplastics, the stability of the materials can be stated in years, not months. But there are exceptions where shelf life can be a serious issue.

Read MoreStop Shopping for a 'Jack of All Trades' Extruder

Some processors try to find “fits all” extruders to cover all processing possibilities. But you’d have to grossly overpower it to achieve this, and that’s expensive up front and will result in inefficiencies over time.

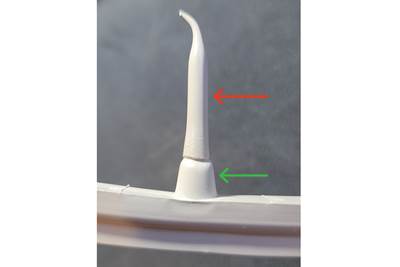

Read MoreAvoiding Common Cosmetic Defects in Molded Parts

Identify familiar flaws and then work to eliminate them with these mold and part design tips, and process considerations.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

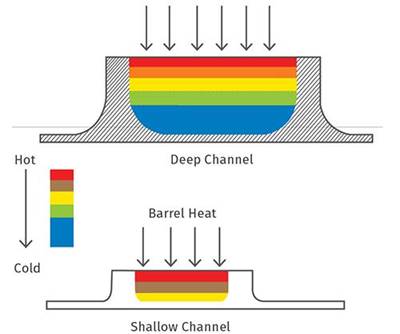

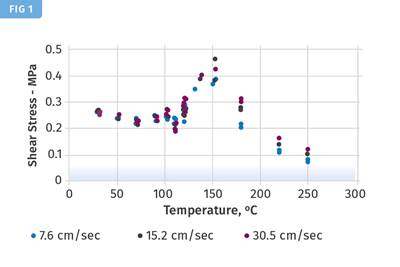

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreOptimizing Barrel Temperatures for Single-Screw Extruders

If barrel temperatures are set correctly and screw design is optimized, the extruder will be operating at peak performance, providing maximum profitability. If not, bad things can happen impacting quality and profitability.

Read More