Air, Land and Sea: Composites Advance on All Fronts

Part II of our report on the leading international composites show includes news for everything from high-tech aircraft manufacturing to boat building and automotive SMC.

Several of the ex citing new technologies at this spring's JEC Com posites show in Paris emerged from the development of the Boeing 787 and Airbus A380 passenger planes. Boeing's 787 Dreamliner, due in 2007, will have the most composites of any aircraft—50% by weight, up from 12% on the Boeing 777—while Airbus Industrie's enormous double-decker A380, due in 2006, will be the world's largest plane and 22% of it will be composites.

But not everything at JEC was aimed at aircraft. Other new products are tailored for automotive, marine, wind-power, and electrical applications. These included developments in thermoplastic composites, reinforcements, tooling materials, gel coats, cleaning solutions, special equipment for prepreg lay-up and cutting tough fibers, and software for simulation, property analysis, cutting, and cost estimating. (Part I of our news report on JEC appeared in June.)

Giant planes spur R&D

GKN Aerospace in the U.K. developed a new molding process, Resin Film Infusion (RFI), to mold parts for the fixed trailing edge of the A380's wings. GKN (which has multiple U.S. locations) lays up combinations of dry multi-axial fabric interspersed with epoxy film. The lay-up is placed in an oven or heated molds, where the resin films melt and impregnate the fiber layers before curing. GKN will use RFI to mold carbon and glass fiber prepregs for 88 different wing panels in Tallassee, Ala., and in the U.K.

As planes get bigger, the composite parts and autoclaves to make them get bigger, too. Aeroform Ltd. in the U.K. is building three autoclaves believed to be the world's largest—30 ft diam. x 70 ft long—to form the entire fuselage of the Boeing 787. Two are being built for Boeing in Wichita, Kan., and the U.K. The third is for Mitsubishi Heavy Industries in Nagoya, Japan.

Think Composites of France (U.S. headquarters in Palo Alto, Calif.) presented Super MicMac, new software for designing composites. It was developed with large aircraft in mind. Think Composites, a supplier of analytical software, was able to model why an ultra-thin ply of carbon-fiber material, only one-third to one-seventh as thick as a conventional unidirectional ply, is more than twice as strong when used in a laminate. The difference is that thicker layers of fibers reportedly induce more internal stresses when highly loaded, which can start micro-cracks.

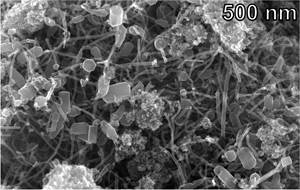

The super-thin-ply material was developed by Itochu Corp. of Fukui, Japan, by blowing air across 12K or 24K tows to spread the fibers into one layer thickness. The resulting unidirectional fabric is only 0.015 to 0.02 mm thick vs. 0.1 mm for standard material. The technology is important for aircraft construction be cause both the Boeing 787 and Airbus A380 have overdesigned composite parts incorporating extra thickness and weight as insurance against micro-cracking and aging, Think Composites says. The Japanese development indicates the ability to produce parts that are not only lighter but also more durable than those currently being produced.

Small process improvements count too as aircraft composites producers ramp up for higher production. Rohm and Haas Electronic Materials introduced a laser-markable tape called RegiStar. It allows a part to be put in a jig where specific points for hole drilling and edge trimming are marked on the tape by a green laser projection system using CAD data. Until now, the part had to remain on the laser jig for the drilling/machining steps. Now, tape is put on the critical spots and retains the laser mark so that the part can be removed from the jig and finished off-line.

Carbon-fiber applications are also expanding into markets outside of aerospace, like boat hulls. SP Systems in the U.K. (North American offices in Quebec) will use its Sprint composite system, which lays up a sandwich of dry carbon fabric and a precatalyzed epoxy resin film (similar to GKN's RFI process). The sandwich is cured in a vacuum bag without an autoclave. SP will laminate the Sprint sandwich against a Core-Cell SAN thermoplastic structural-foam core to build M Ship Co.'s double-hulled M80 Stilletto stealth boat for the U.S. Defense Dept.

Thermoplastic composites

Some of the most exciting parts seen at the show were developmental thermoplastic composites made by a variety of methods. For example, FITS Technology in Driebergen, Netherlands, a five-year-old spinoff from the Technical University of Delft, commercialized its flagship product—a Foamed In-situ Thermoformable Sandwich. This patent-pending composite sheet has a thermoplastic core that is foamed and bonded to layers of surface reinforcement in one step. The surfaces are chopped-fiber mats of dry glass, carbon, or thermoplastic fibers. In Paris, FITS showed panels of polyetherimide (GE's Ultem) foam bonded to commingled PEI/glass-fiber face sheets. FITS parts are 15% lighter than honeycomb structures and have greater freedom of design, much faster production cycles, and lower cost, the company claims. It is targeting aircraft galleys, luggage bins, trolleys, floor panels, and seating.

Jacob Composite GmbH in Germany showed the prototype of an automotive thermoplastic composite front-end structure, developed with Lotus Engineering of the U.K. and dubbed the Ecolite (Efficient Composites Lightweight and Thermoformed) project. Jacob uses a new method that starts with layers of woven nylon and fiberglass, consolidates these fabrics into sheet, and then pressure forms it. The structure is made in two halves, which are then high-frequency welded. The surface is smooth, but not Class A.

Ahlstrom Glassfibre Oy in Finland introduced glass with sizing designed for a radically new type of thermoplastic composite. Ahl strom's R 338 glass is designed for the new cyclic PBT (CBT) resin from Cyclics Corp. in the U.S. This resin is supplied as a low-melting oligomer with a water-like viscosity that easily impregnates reinforcements. Upon further heating, the oligomer cures into an engineering thermoplastic (see Learn More box). A second glass product for CBT, which will be 20% stronger than R 338, is in development. It will allow a TP composite to get the same mechanical strength as epoxy, Ahlstrom says. One target is windmill blades.

Soft foam turns rigid

FoamPartner Fritz Nauer AG in Switzerland showed a new soft PUR foam called StructUre that converts to a rigid structural core material in seconds when crosslinked with an electron beam. Its first product is StructUre E720. The foam can be used in its soft state or e-beam treated for different levels of stiffness. This opens new design possibilities because soft foam is easier to cut accurately and form into more complex shapes than rigid foam. Soft foams can also be compressed by up to 90% of their volume to save on shipping.

New tooling materials

Several companies showed new materials to make models and molds faster. Chemval Srl in Italy, a producer of polyester and epoxy resins and gel coats (North American offices in Quebec) introduced a rigid, two-component PUR/polyurea hybrid for CNC milling. Stratycoat 149 can be sprayed without solvents at 280 to 300 F and cures in 1 min without bubbles or porosity. It can also be used to cast solid parts, curing in 3 hr and hard enough to be milled after 6 hr.

Huntsman Advanced Materials launched a new epoxy modeling paste called Ren Paste XD 4618-1, designed to allow ship builders to build molds for hulls of any size.

Nord Composites in France showed a new no-shrink vinyl ester tooling material, RM3000, made with fillers and no-shrink additives. Compared with typical orthophthalic polyester tooling resins, vinyl ester gives better heat and chemical resistance, but its drawbacks are higher shrinkage and extended cure times (up to weeks). RM3000 cures in 48 hr and is available in the U.S. for sampling.

Scott Bader Composites in the U.K. launched a rapid-cure tooling resin called Crystic Fastlam 3000A. which cures in 24 to 48 hours. The 25% glass-filled, thixotropic polyester uses low-profile additives to reduce shrinkage. It contains 25% styrene.

New gel coats

Several companies showed new specialty gel coats. SP Systems introduced GC 2000 epoxy gel coat for better adhesion to epoxy windmill blades than polyester gel coats. It's also more hydrophobic than polyester, so it picks up less airborne dirt.

DSM Composite Resins showcased Neogel VE 8393, a sprayable vinyl ester tooling gel coat with long-term gloss retention. A brushable version, Neogel VE 8394, is in customer trials and will be available soon.

Reichhold showed a developmental vinyl ester barrier coating to be used between gel coat and core. It replaces a hand-laid layer of glass and vinyl ester. After the gel coat is sprayed and dry, the new barrier coating can be sprayed with the same spray gun without cleaning in between. The system is being tested in Europe for a marine application.

Better-looking SMC

Byk-Chemie introduced a processing additive for low-profile and Class A SMC. Byk-P 9080 is said to significantly improve flow, surface quality, bondability, and paint adhesion. It replaces the traditional stearate release agent, thereby improving color uniformity in pigmented parts.

News in reinforcements

Ahlstrom introduced a novel chopped-strand mat called MLS 650, made by combining very short (50-mm) and very long (200-mm) fibers. It's said to be intermediate in properties between chopped and continuous glass mats. It has a semi-soluble binder and comes in weights of 300, 450, and 600 g/m2.

For closed-mold infusion processes, Ahlstrom also introduced a new flow medium, called Multi-Flow, bonded to a multiaxial knitted fabric.

Saint-Gobain Technical Fabrics launched Multimat-Lite, a drapable 3D reinforcing mat for closed-mold processes. Unlike previous all-glass Multimat grades, it has a knitted core of blended glass and PE fibers for lighter weight, with chopped-glass mats stitched to both surfaces.

Owens Corning introduced a new "low seed," single-end Type 30 roving for pultruding long-rod insulators used in medium- and high-voltage transmission. Called SE 8400 LS, it is made of boron-free Advantex glass and has very low levels of "seeds" or microscopic voids that can cause electrical failures. SE 8400 LS roving comes in yields of 113, 103, and 52. The heavier 52 yield requires fewer ends of roving to produce a part of equal glass content.

PPG Industries is starting U.S. production of a product previously introduced in Europe. TufRov 4599 continuous-strand glass is designed for direct long-fiber thermoplastic (D-LFT) compounding and molding without need for a coupling agent.

Clean up without acetone

Another aqueous soap is available to replace acetone for cleaning resin rollers and brushes. The environmentally friendly soap, RST-5, was developed by Mulder-Hardenberg GmbH in Germany and has been produced in the U.S. for about 18 months by The United Soap Factory. Early U.S. composite users include two Florida boat builders, Wellcraft and Intrepid Boats, as well as Stonetek, a California maker of stone-filled composite counters. Resins settle out as sludge, allowing the solution to be reused for long periods. The sludge can be disposed of as harmless cake. RST-5 is sold as a concentrate to be diluted 20:1 in hot water.

Novel equipment

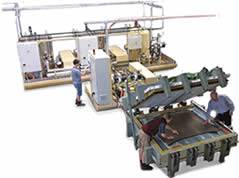

Coriolis Composites, a French technology development and engineering company, showed a prototype of what's said to be the first system to automatically lay up continuous glass, carbon, or nylon fiber starting with dry fiber. It targets large parts like aircraft fuselages and boat hulls. The fibers are coated with two-component epoxy in the application head mounted on a six-axis robot. Competing systems use spools of prepreg fiber, which is more expensive and has to be stored cold.

Coriolis's pilot machine manipulates the head with a lighter, faster robot than those typically used for prepreg. It cuts the continuous fiber and restarts a new strand automatically. The pilot machine is available for testing and prototyping with simulation software for part development. Commercial machinery will be available in early 2006 in custom sizes costing over $1 million.

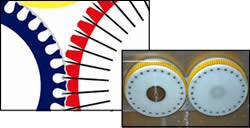

Several companies showed new technologies to break PET fibers instead of cutting them. That causes less wear on knives and uses less energy. Van der Mast Industrial Innovations in the Netherlands introduced "Chopcot," a fiber-cutting device with two counter-rotating rollers. One has short blades mounted like paddles on a water wheel. The other has corresponding slots. As fiber passes between the rollers under tension, the knives in one roller push the taught fiber into the corresponding slots in the other roller, breaking the fiber cleanly.

GEPO Genoud Polyester in Switzerland showed its new "Kutcut" machine, patented earlier this year, which also breaks, rather than cuts, PET fiber.

Jenoptik Automatisierungstechnik GmbH in Germany showed a portable or robotic laser system for cutting or perforating glass, thermoplastic, and ceramic-fiber fabrics.

Software developer Grafitroniks in France showed new nesting software developed for Zund System technik AG, a 20-year-old Swiss maker of camera-guided, automatic cutting machines for prepregs, foams and cores. Zund recently opened a U.S. office in Franklin, Wis.

Software for composites

Galorath Inc. of the U.S. won the top JEC prize for Aeronautics and Aerospace with a new module for its SEER-DFM cost-analysis software. Developed with Airbus in the U.K., the new Detailed Composite module, compares costs of making a part with five composite processes—hand lay-up, automated tape lay-up, RTM, liquid resin infusion, and resin film infusion. Custom processes can be added also.

Previously, SEER cost analysis considered only the number of layers in a laminate and whether or not it had a gel coat. The Detailed Composite module analyzes the cost of hand labor and time required, including inspection and rework. It even calculates a learning curve for workers, anticipating that as they make parts, they get better and speed up.

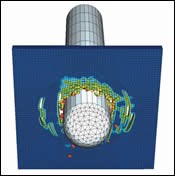

E-Xstream Engineering SA in Belgium, an offshoot of the University of Louvain, developed new interfaces that link its Digimat structural analysis software to Moldflow and Sigmasoft injection molding simulation and to Abaqus finite-element structural analysis. Combinations of these programs can now simulate injection molding of a long-fiber thermoplastic part, predict fiber orientation, and analyze the mechanical behavior of the part—even simulate impact test results. In Europe, this enhanced Digimat software is being used by Plastics Omnium, Solvay, and Braun.

Delcam showed the latest release of its Powershape software, Version 6, with a new unwrapping function. It flattens a complex 3D lay-up to show how to cut fabric reinforcements, allowing for edge overlaps and joints

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Engineering Thermoplastic Processes Like a Thermoset

The first quarter of 2005 will see the first commercial production of a dramatically new family of resins that offer the processing advantages of liquid thermosets plus the properties and recyclability of engineering thermoplastics.

Read MoreComposites: New Rapid Molding Technologies and Unusual Reinforcements at Paris JEC Show

New molding technologies seen at the JEC Composites Show in Paris in April promise dramatically faster cycles than are achievable with autoclaves or RTM. One novel technique rapidly heats and cools a thin tool by "floating" it on a flexible bladder—similar to a water bed—that is flooded with heat-transfer fluid.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More