color

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

How to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreThe Steps to Consistent Color in Plastics

Unlock the secrets to flawless color duplication in your production processes. Discover why expert color replication is paramount for maintaining quality, reducing costs, and ensuring client satisfaction and retention. Download now to gain insights that will revolutionize your approach to color control.

Read MoreColor Masterbatches for Optical Fiber Cable PBT Jacketing

Ampacet’s ElTech line now includes a range of high-performance masterbatches based on a PBT carrier resin.

Read MoreMore Efficient, Precise Blending and Drying Solutions

NPE2024: ABS debuts new blending, drying and repelletizing products in Orlando, plus a new color analyzer.

Read More'Dual Action' Purging Compound Accelerates Color Changes

NPE2024: Shuman Plastics’ Dyna-Purge Division launches Dyna-Purge L, extending its “3X technology.”

Read MoreUpdated Controller for Sealed Gravimetric Liquid Color and Additives System

NPE2024: Riverdale Global’s new RGS controller features and intuitive set-up procedure.

Read MoreRiverdale Global Showing Latest Innovations and New Satellite Location in Wisconsin

NPE2024: Live demos of updated RGS controller are among the highlights at its Wisconsin facility that will house the ‘new’ color R&D lab.

Lilli Manolis Sherman

Contributing Editor, Plastics Technology Magazine

IMM Cells Display Communications, Energy Measurement and Energy Recovery

NPE2024: Wittmann is featuring five injection molding machines incorporating its range of robotics and auxiliaries, with all products employing industry 4.0 communications, energy measurement and a brand-new red color.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreTosaf’s Investments in North America Result in 40% Increase in Production Capacity

Backed by a global presence, Tosaf provides localized additive and color solutions, and services for the plastic industry in North America.

Read MoreAdditive Masterbatch for Permanent Etching on Black and Dark Plastics Products

Ampacet’s new ColorMark reveals color in dark plastic surfaces exposed to laser light

Read MoreFlake Sorter for Simultaneous Separation By Color, Polymer, Transparency

Tomra has introduced a new model of the Innosort Flake for sorting flakes of mixed waste plastic for recycling.

Read MoreTechmer Buys Advanced Color Technologies

Deal will expand Techmer’s in colorants and additives in synthetic fibers.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Injection Molder Changes Up Color Changes

An injection molder of trash cans, pallets, totes and other plus-size components, Rehrig Pacific’s machine fleet is composed of larger tonnage presses whose size makes material changes at the feed throat a potentially dizzying exercise.

Read MoreAdditive Masterbatches for Monomaterial PE Film Applications

Ampacet’s Biax4CE portfolio of additives and white color concentrates designed for MDO-PE and BOPE applications.

Read MoreDSM Launches an AI Powered Color & Mechanical Properties Prediction Tool

Called Lucidiris, this prediction tool can reduce time to market when developing colors of high-performance materials for a variety of applications.

Read MoreNovel System Produces Color on Demand

Ampacet’s FluxQF technology features a quick-dispersion universal carrier with novel machinery that provides automated color blending in quantities down to 50 lb.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreSorting Mixed Plastics by Color and Type

Steinert will demonstrate plastic sorting technology at K 2022.

Read MoreGet Color Changes Right In Extrusion Blow Molding

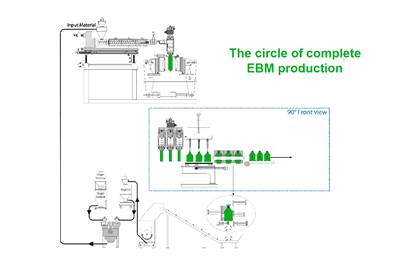

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

SPE’s Automotive Division Names 2022 Hall of Fame Winner

First mold-in color weatherable grille used on the 1987 VW Golf to be celebrated at the 51st annual SPE Automotive Innovation Awards Competition & Gala.

Read MoreHigh-Dispersion Rotor for Compact Processor

Billed as ideal for processing fiber grade, high color carbon black, and color concentrates.

Read MoreCoke Makes Bottle Changes to Boost Recycling

Sprite bottles will be clear, while Dasani bottles will be made with recycled plastic.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreColor-Measurement for Extrusion, Molding

System helps processors control the cost of quality due to color variations, using real-time color data for QC analytics and color optimization.

Read MoreColorants with Synthetic Leather Look for HDPE Blow Molded Packaging

Ampacet’s Synthetic Leather color palette projects luxury look of leather.

Read More