Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Monolayer PCR bottles in back are dull gray, while multilayer ReCo bottles in front show off coloring flexibility. Cross-sectional view shows how multilayer technologies can hide even very contaminated PCR. Source: W. Müller GmbH

With each passing year, governments worldwide enact new legislation dictating the extent to which postconsumer plastics must be recycled and how much of that PCR should be incorporated into new plastic products. This regulatory landscape presents a formidable challenge for converters who must navigate the complexities of acquiring and processing these materials.

At W. Müller, we are known for our production of extrusion heads for blow molding machines. What many may not realize is that we operate two technical centers that have provided us with early access to recycling materials in collaboration with material manufacturers and recyclers to conduct comprehensive tests under varying conditions. Over the years, we've evaluated more than 50 different recycled materials from over 15 manufacturers globally, testing them across all our technologies, from one to seven layers, in bottles from 70 ml to 1 L. This research has also enabled us to observe the evolution of commercially available PCR materials over time.

Despite advances, blow molders still face numerous challenges in processing these materials. This article explores key challenges such as processability, odor, topload strength, migration, drop-test results, black specks, differences in color and material availability. The relevance of these challenges varies greatly depending on the regional infrastructure for material separation, collection, sorting and processing.

W. Müller’s two technical centers have evaluated more than 50 different recycled materials from over 15 manufacturers globally, testing them in one to seven layers, in bottles from 70 ml to 1 L.

The Best Case Scenario

Some PCR materials stand out for their excellent processability. They are typically colored white, ivory or a very light gray. In our tests with those materials, we started molding virgin HDPE into bottles and then changed to the good-quality PCR. We continued making bottles, adjusting the die gap to achieve the same bottle weight. Processing was very easy, there were no parison length variations, and the process ran stable. Some bottles had a couple of dark specks, but nothing to worry about. These materials still had a characteristic PCR smell — however, it was more the smell of a not too overpowering cleaning agent. These materials ran well even in monolayer bottles.

Nonetheless, this high-quality PCR has two big problems: price and availability. A big effort goes into sorting, cleaning and removing volatiles from waste to make that PCR material. All this takes energy and resources, which are reflected in a high price per pound. If price is not an insurmountable obstacle, then you will face the next problem: After sorting so much waste out of the stream to get pure HDPE, the yield of high-quality material is relatively small. If everyone decides to make a 100% PCR bottle out of these premium PCR materials, there will only be enough material available for a few customers.

The Worst Case Scenario

FIG 1 – On left is a monolayer bottle of 100% PCR whose contaminants caused foaming and bottle distortion. On right is a three-layer ReCo bottle with the same PCR in the center main layer, while inner and outer virgin layers provide processing and mechanical stability and aesthetic appearance. Source: W. Müller GmbH

Conversely, some recycled materials present formidable challenges. In one case, we tested a PCR material for a recycler. We started with monolayer construction. As soon as the material came out of the die, it was obvious that that was not a material for blow molding. It produced a foamed, black/green parison with a lot of fumes, a horrible smell and some sort of oil dripping out and sticking to the die, pin and blow pin. The bottle? Nonexistent. The rough foam structure would not allow a bottle to be formed. What was supposed to be a 1 L round bottle looked like an ugly flower vase instead (see Fig. 1).

Adding coextruded outer and inner layers did not contribute much. This PCR material had some nylon in it, which has a higher melting point than HDPE. The unmelted nylon, together with the rough foam structure, still caused big holes in the bottles. After many tries with drying, filtering and changing processing parameters, it was possible to make three-layer bottles with 50% of this material in the center layer.

The good news is that the average real-world scenario lies somewhere in between the best and worst case scenarios described above. However, if it was possible to make the worst case scenario processable with three-layer technology, then there is a lot of hope for most recycled blow molding materials out there.

Limited availability and high cost of the best quality PCR can be offset by using multilayer blow molding technologies.

Multilayer Technologies: How to Choose?

There are many multilayer blow molding technologies out there. We often hear about coextruding 11 layers or more in the film industry. But in blow molding, seven layers is the practical maximum. It is possible to make a head with more layers, but we haven’t found an application that actually needs more than that.

FIG 2 – A variety of multilayer technologies are available to provide specific functions – aesthetic, functional and/or processing-related. Source: W. Müller GmbH

At W. Müller, we offer, in addition to our single-layer technology (Mono), a diverse array of multilayer technologies (Fig. 2). Among these are DeCo and ReCo, comprising two (DeCo) or three (ReCo) layers of an identical material type (such as all-HDPE with layers of virgin and PCR). Additionally, our portfolio includes CoEx technologies, which entail coextrusion of different material types to achieve specific performance functions or properties, such as coextruding HDPE with EVOH or nylon for UV barrier, chemical barrier or oxygen barrier.

Many of you hear “multilayer” and immediately think that multilayer is bad for recycling. That is only true if you combine different polymers with a fairly large proportion of the minor component — for example, more than 6% EVOH oxygen barrier in an HDPE bottle. However, W. Müller heads are capable of making bottles with EVOH layers under 6%, which give you a fully recyclable bottle with a barrier.

Furthermore, DeCo and ReCo are multilayer technologies that use only one polymer type (such as only HDPE or only PP), which makes the bottle 100% recyclable in any recycling stream.

Multilayer Technologies for PCR Processing

DeCo and ReCo offer monomaterial multilayer solutions for processing PCR, ensuring recyclability while maintaining product integrity. DeCo consists of two layers, usually a thicker PCR inner layer and a thinner outer layer with virgin material and color masterbatch (Fig. 3). This enables you to color your bottle and hide the PCR while minimizing the use of masterbatch. The layers are easily customizable, so you can vary the thickness depending on your needs.

FIG 3 – W. Muller’s two-layer DeCo technology facilitates coloring the bottle at minimum cost while hiding the PCR layer. Source: W. Muller GmbH

ReCo is a three-layer technology with a thinner outer layer, usually virgin with masterbatch; a thicker main or center layer, usually PCR with regrind; and an inner layer, usually just virgin (Fig. 4). The goal here is to save masterbatch, cover the PCR material, avoid contact between your product and the PCR, and improve the mechanical properties of the bottle.

FIG 4 – Three-layer ReCo technology can save masterbatch costs, avoid contact between a bottle and its contents, and improve mechanical properties of the bottle. Source: W. Muller GmbH

The good thing is that if you have a machine running with monolayer, you can retrofit this machine with a new W. Müller head to process with DeCo or ReCo. With a multilayer head from W. Müller, you have the flexibility to run either multilayer or monolayer bottles with that same head.

Processability Enhancements

Many customers have complained about stability problems while processing PCR materials. Changes in parison length can cause problems such as fluctuation in bottle weight and changes in the position of the thickness profile, which lead to poor topload results.

The goal was to recognize and capture these differences objectively, and see if it is possible to reduce them. This project was a cooperation between the additive producer Baerlocher, recycler PreZero (active in Europe and the U.S.) and W. Müller. Baerlocher provided the additive Baeropol RST, which is made from a combination of commonly used, nonantioxidant polymer additives that together support polymer stability. This additive was compounded into a batch of PreZero PCR HDPE material. Then, batches of PCR HDPE with and without additive were sent to W. Müller for testing.

On our lab machine, cameras were installed on the front and on the side to take a picture of the parison at the same point during each cycle, which software analyzed to calculate the parison length. The gross and net weight of each bottle were measured, and the melt pressure in the extruder was controlled.

The process with the least variation in gross weight, melt pressure and parison length was that of the virgin bottle. The process with the most variation was monolayer PCR material without additive. When comparing the process variation for the PCR with and without additive, it was observed that the additive reduced the process variation when using the monolayer and ReCo technologies. It was also noted that using ReCo improved process stability for both the stabilized and unstabilized material. The variation in the parison length and melt pressure of the stabilized ReCo bottle was only slightly higher than that of the virgin bottle. This means that processing PCR with three layers can improve the stability of your process when compared with processing monolayer PCR.

FIG 5 – When HDPE waste arrives at a sorting facility, white bottles are segregated into one stream that becomes white or ivory PCR pellets (left), while all other colors are combined into a stream that becomes gray pellets (right). Source: W. Muller GmbH

Using color masterbatch only in the external virgin layer of a multilayer bottle can significantly reduce costs while improving the color match and hiding impurities in the PCR layer underneath.

Addressing Color Variation and Impurities

Have you ever thought about how materials are sorted and why a lot of PCR materials are gray? When used plastic arrives at the sorting facility, white HDPE bottles usually will be sent to the white HDPE stream and colored bottles will be sent to the colored stream. Because all colors sent to the colored stream are mixed together, the resulting color of this mixture is gray. Depending on the colors sent, you get different shades of gray, but gray nonetheless. Because of the different shades of white and natural-color bottles entering the white stream, the result is a whiteish ivory material (Fig. 5).

It is tempting to buy those ivory colors and then add some color to make a nice PCR bottle. This is not the best approach to close the loop because you are taking material from the limited white stream and on the next product life cycle returning it to the gray stream, which few will want. If you buy the ivory PCR and mix in some white, then the bottle will end up again in the white stream and the loop is closed.

The only way to achieve widespread circularity is to find a place for those gray materials in PCR bottles. Does that mean that on your next trip to the drugstore you will only find gray PCR bottles? Not with our ReCo technology adding a virgin layer with color on the outside to cover the gray PCR material. With the DeCo and ReCo technologies, it is possible to use those gray PCR materials in nicely colored bottles. How much PCR can you use in this way? It depends on the technology and regrind use, but normally up to 80% in DeCo without regrind and up to 70% in ReCo without regrind or about 60% with regrind.

It is of course possible to use a gray PCR material in a multilayer bottle and color the outer layer white. This is not recommended because the bottle would end up contaminating the white stream with gray materials.

Some of you might think you can just color the gray PCR materials. This is possible, but the resulting color of the bottle will be nowhere near your original color, even if you increase your masterbatch use level from 4% to 8%. You will have a colored bottle, but it will still have a grayish tone and you will be spending double the money on masterbatch. Better to make a three-layer bottle and just color the outside layer. You are free to increase the amount of masterbatch in the one layer; you will still be saving money. The best thing? Your color will be either the same as your original bottle or a lot closer to it.

FIG 6 – Compare colors of a monolayer PCR bottle with 6% masterbatch (left), monolayer virgin bottle (center) with the same amount of masterbatch, and ReCo bottles with different three-layer structures and equal or lower masterbatch levels in just the outer virgin layer. Source: W. Muller GmbH

Let’s compare monolayer bottles (Fig. 6). Suppose your bottle weighs 70 g and you used 4% masterbatch in your virgin bottle. If you double the masterbatch level to 8% when using a gray PCR, you will be going from 2.8 g masterbatch to 5.6 g. If you make that same bottle in three layers, where the outer layer is 20% of total thickness, and you add 4% masterbatch only to that layer, you will be using only 0.56 g of masterbatch. Even if you double the amount of masterbatch in that outer layer, it is still 1.12 g, which is 60% less than you had in your virgin bottle. Imagine saving 60% in masterbatch costs and still getting a better color match than using monolayer? And you have an added benefit when using ReCo: Any black specks are covered by the outer layer (Fig. 7).

FIG 7 – Monolayer PCR bottle (left) shows black specks, which are hidden in multilayer ReCo bottle (right). Source: W. Muller GmbH

Enhanced Mechanical Properties

For the topload test, three bottles were produced: a virgin monolayer bottle, a PCR monolayer bottle, and a ReCo three-layer bottle with 70% PCR in the main (center) layer. This same test has been done with different bottle geometries and sizes.

Depending on the virgin material and the PCR material being used, the virgin bottle will most likely have the highest topload strength and the PCR monolayer bottle will have the lowest topload. With the ReCo structure you will see an improvement in the topload strength.

This test was also performed with the bottles made with PreZero PCR HDPE material and the Baerlocher additive. The additive also improved topload. Interestingly, the topload for the three-layer stabilized bottle was higher than the topload of the virgin bottle. That means that the ReCo technology alone already improves the topload, but material stabilization together with the ReCo technology could help reach or even improve topload results while using PCR.

Also, when comparing results of using monolayer with PCR and regrind and ReCo with PCR and regrind, improved topload was observed on the ReCo bottles (Fig. 8).

FIG 8 – Topload strength comparison of virgin (left), monolayer PCR (center) and ReCo bottle with PCR (right). Source: W. Muller GmbH

These results depend highly on the virgin and PCR materials being used. Bottle size and geometry also play a role.

Some cheaper, more available HDPE PCR materials will have some PP in them. This comes from, for example, caps that were not sorted out properly. PP in HDPE will cause problems with the welding seam, which will not close properly. This will cause problems in the drop test, where the bottle will probably break at the welding seam.

A test was performed where a virgin bottle, a PCR monolayer bottle, and a ReCo bottle were each dropped a maximum of five times from 6.5 feet. The virgin bottle survived all five falls without breaking, while the PCR monolayer bottle broke after about two falls. The inner and outer layers of the ReCo bottle helped stabilize the bottle, and thus the bottle survived all five drops, just like the virgin bottle (Fig. 9).

FIG 9 – In drop tests, monolayer gray PCR bottle (left) split at the weld seam after two falls, while white ReCo bottle with PCR in main layer (right) survived five falls intact. Source: W. Muller GmbH

Reducing Migration

The Regulation (EC) No 1935/2004 is an EU legislation that governs the general requirements for materials and articles intended to come into contact with food. It establishes the principles and procedures for assessing the safety of such materials and articles, and includes provisions for labeling and traceability. Our tests were performed according to that legislation. They measure the migration of substances from the plastic material into the contents of the container. These results were evaluated for use in cosmetics containers.

One test measured global migration in a monolayer PCR bottle and a ReCo PCR bottle. Even though both bottles had a global migration under 10 mg/dm² (which is the legal limit), it is important to notice that the monolayer PCR bottle had a global migration of 4 mg/dm² while the ReCo bottle had a global migration under 1 mg/dm². This was repeated with a different PCR material, and the results were similar — the monolayer PCR bottle had a global migration of 3 mg/dm² while the ReCo bottle had a global migration under 1 mg/dm².

We also observed that fewer substances migrated from the ReCo bottle. Many of the substances migrating from the monolayer bottle could not be found in the test of the ReCo bottle. The substances that would still be found migrating from the ReCo bottle had, in most cases, a lower concentration. Only two substances were found in higher concentrations from the ReCo bottle than the monolayer bottle. These substances were additives that migrated from the virgin layer.

Migration tests with four different materials and two different bottle sizes/geometries showed that the migration in the ReCo bottles is under the legal limit and therefore safe to use in cosmetic products, both leave-on and rinse-off.

It is important to mention that the inner layer is not to be considered a functional barrier and will not allow you to use a non-food-grade PCR material for a food-grade application. However, it can help make your product safer. If you are making a cosmetic product and are using a substance that has a concentration limit, you would not want that substance to migrate from the PCR into your product in amounts sufficient to cause you to exceed the regulatory limit.

Choice of Head and Extruder Matters

Depending on your chosen technology (be it DeCo, ReCo or CoEx), the required head and extruder setup can vary significantly. Furthermore, the selection of a head producer can significantly impact the outcomes of your operations.

When processing PCR, precision in the design of both the head and extruder is paramount to accommodate the necessary multilayer configurations. This precision ensures exceptional tolerance for MFI fluctuations, which is crucial when transitioning between materials and colors. Ensuring that settings remain valid across transitions minimizes downtime spent adjusting parameters, thereby maximizing productive output.

At W. Müller, our team meticulously optimizes the channels of the head to streamline plastic flow, preventing the accumulation of deposits and abrasions. Neglecting this crucial step can lead to the introduction of additional black specks that may be erroneously attributed to the PCR material itself.

To effectively reduce masterbatch and plastic consumption, it's counterproductive to utilize a head with prolonged color and material changeover times, as each transition results in waste. Rapid changes in color and material not only bolster flexibility but also enhance overall productivity.

When processing multilayer materials, achieving uniform material distribution is vital. Poorly designed heads lead to inconsistencies in distribution, which lead to variations in layer thicknesses, resulting in either overuse of more expensive materials or localized thinning of inner layers in the final product, potentially leading to increased migration risks. Therefore, meticulous attention to material distribution is essential to ensure both cost-effectiveness and product quality. This is achieved through the use of simulation software, which enables us to model the flow channels and identify potential design issues before manufacturing begins. By simulating the flow dynamics, we can pinpoint and address any problematic areas, ensuring optimal material distribution and minimizing the risk of uneven layer thicknesses. This proactive approach not only enhances product quality but also saves valuable time and resources by mitigating issues before they arise during production.

With multilayer technologies, it is possible to improve the mechanical properties of bottles while using PCR materials. A colored outer layer enables you to cover gray and black PCR materials, black specks and impurities, while saving in masterbatch and getting a color closer to your original color.

The inner layer can help you reduce the substances that migrate into your products. The easy adjustment of the layers, depending on availability of the PCR materials, can help you to stay flexible.

It is important to make an informed decision when switching to PCR. Therefore, it is helpful for you to send us your virgin and PCR material ahead of time. We can (depending on the size) help you adapt your mold to our machine, and we can sample and test the bottles for you. That way, you can pick the technology and materials that are best suited to your application.

About the Author

Varinia Lück earned a bachelor’s degree in chemical engineering from Universidad del Valle de Guatemala and a master’s degree in product management from the University of Oulu in Finland. After internships at Colgate-Palmolive and A. Schulman (now LyondellBasell), Lück joined W. Müller GmbH in 2018, where she serves as head of the Technology Center. She is responsible for R&D, with a particular focus on circularity (using recycled materials and biomaterials), barrier technologies, color change and foaming. Contact lab@w-mueller-gmbh.com; mullerheads.com.

Related Content

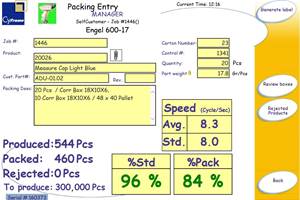

Use Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreBlow Molder with a Mission: CKS Packaging Shares Gains Of Its Phenomenal Growth

From three machines in 1986 to 27 plants nationwide today, this family-owned processor has prospered through unwavering customer service, committed employees and dedicated service to its community.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreRead Next

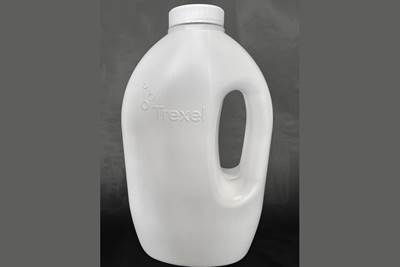

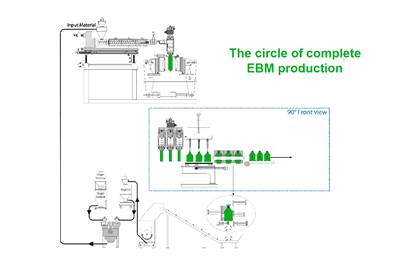

Trexel & W. Müller Team Up on Multilayer Foam Blow Molding

MuCell technology gains new momentum in blow molded packaging through this partnership of a leader in physical foaming with supercritical gases and a leader in coex blow molding hardware and controls.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreCompact Screen Changers for Processing PCR

NPE2024: W. Müller shows off new screen changers in response to increasing interest in blow molding recylates.

Read More