How Yeast Could Give Rise to Bioplastic

Researchers work to scale up a biomanufacturing process for succinic acid, an important building block for industrial chemicals and a biopolymer precursor.

Succinic acid is a building block of a variety of industrial chemicals, such as tetrahydrofuran, and can be used to produce polymers, such as polybutylene succinate (PBS), a biodegradable polyester. Currently, the main industrial methods produce succinic acid from petroleum derivatives, but living cells produce it naturally. Professor Huimin Zhao, of the University of Illinois at Urbana-Champaign (UIUC), believes the right organism could be the key to more sustainable production. Dr. Zhao’s team uses yeast to produce succinic acid from a readily available biomass, sugarcane.

Efforts to produce succinic acid via biological pathways have been ongoing for decades. Past efforts have been held back, according to Dr. Zhao, by the use of acid-intolerant bacteria to ferment sugars. As the product builds up, bases must be added to control the pH of the reactor environment and keep the cells alive. An additional acidification step is required to produce succinic acid from succinate, as well as a purification step to remove the added base chemicals. By starting with an acid-tolerant yeast, Issatchenkia orientalis, the UIUC group has increased efficiency and reduced the waste products generated by skipping these steps.

Using genetic engineering, researchers selectively regulate the expression of proteins that enable or inhibit the fermentation of succinic acid inside yeast cells. Source: University of Illinois Urbana-Champaign

“We isolated this organism from the environment that can tolerate a low pH, and we developed a genetic engineering toolbox to manipulate the organism to overproduce succinic acid,” Zhao says.

The yeast produces succinic acid naturally, but in small quantities. By manipulating the DNA, researchers were able to alter the metabolism to increase productivity of the fermentation process. They have also developed an electrochemical process for purifying the end product of the fermentation process.

This bioreactor maintains conditions for producing succinic acid, enabling researchers to refine their process at a larger scale than flask experiments. Source: University of Illinois Urbana-Champaign.

In 2021, the UIUC succinic acid research was supported by a grant from the BioIndustrial Manufacturing and Design Ecosystem (BioMADE), enabling researchers to move their previous work up to the level of pilot production scale. Biomade supports projects that contribute to building a “sustainable, domestic, end-to-end bioindustrial manufacturing ecosystem.”

To make a substantial impact on the industry, this approach will need to be scaled up significantly. Smaller volumes are easier to control and place less stress on cells. “Most of our work developing fermentation processes is done at no more than 10 liters, often only one liter, and you can control the conditions very well. When you scale up to several hundred liters or even thousands of liters, it becomes very hard. The biggest challenge is mixing: If you have poor mixing, the productivity will decrease,” Zhao says. Already, researchers have progressed from shake flasks in the laboratory to pilot scale reactors at 100 and even 300 liters.

Commercial Feasibility and Environmental Impact

As part of the pilot scale study, the UIUC team conducted a techno-economic analysis (TEA), which predicted that the biomanufacturing process of succinic acid would be financially viable, with costs comparable to or better than incumbent means of production from petroleum. Simulations of a biorefinery design to process sugar cane all the way to succinic acid resulted in a minimum product selling price of $1.70/kg, $1.06/kg and $1.37/kg for three different simulated scenarios (each with its own assumed yield, concentration and productivity).

The researchers also performed a life cycle assessment (LCA), which showed that the process could reduce the global warming potential by 34-90% relative to fossil-based succinic acid production (cradle-to-grave scope).

“By producing succinic acid with sugarcane, reliance on petroleum and greenhouse gas emissions will be greatly reduced, along with cutting costs,” says Melanie Tomczak, head of programs and CTO at BioMADE.

Next Steps

Since completing the pilot study research, published in Nature Communications, the UIUC team has been focused on improving yield, and is also discussing licensing with potential partners. Zhao explains that the high titer (an expression of the concentration of product in a solution) and yield are encouraging for future opportunities.

“The titer is already high, more than 100 grams per liter, but the yield is not yet to the theoretical limit,” Zhao says, “so although it is already economically viable based on the TE analysis, we still have room for improvement.” Yield of the process can be optimized by optimizing the organism itself, engineering the metabolism to increase fermentation.

Scaling up to larger quantities will ultimately require getting an industrial manufacturer involved. “In the university, we don’t have a larger production facility, so we need a company that is interested in the technology, to do it on the industrial scale,” Zhao says.

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

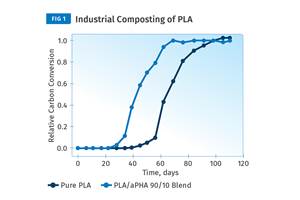

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreAvantium and U.S.’s Origin Materials Aim to Accelerate Production of FDCA and PEF

The partnership aims to bring together both companies’ technology platforms to produce FDCA from sustainable wood residues on an industrial scale.

Read MoreICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MoreRead Next

An Encouraging Sign for Bioplastics

When a global packaging giant buys a stake in a bioplastics firm, that looks like a vote of confidence in a still-emerging materials field.

Read MoreWhat's Ahead for 'Green' Plastics: Look for More Supply, More Varieties, Better Properties

Major chemical companies are investing big bucks in new plants and technologies to produce plastics from annually renewable sources, not from petrochemicals.

Read More