In-Person Exposition Provides a Rich Environment for Discovery of Trade Trends and Technology Applications

Serendipitous Learning Opportunities at PTXPO Underscore the Value of Being Present.

PTXPO closed after three days of conversations, presentations and exhibitions. The volume and variety of content bestowed the paradoxical quality of feeling long and yet flying by. Just two years ago it seemed like a gathering like this might be a thing of the past. And yet, trade shows are back, with irreplaceable learning opportunities.

PTXPO brought learning opportunities to the Donald J. Stephens center in Chicago.

Photo Credit: Matt Stonecash

The curious attendee finds not only live demonstrations, up close encounters with major equipment, and edifying tech talks, but also serendipitous opportunities to learn from exhibitors who spend their days engaged in a wide variety of work in the industry. In the following paragraphs I’ll share a few of the things I picked up from conversations at PTXPO.

Diagnostic Applications in Plastics

Rechner Electronics displayed a variety of sensors for detecting fluid, weight, etc., and discussed how real-time, actionable information can make manufacturing safer by detecting leaking fluids, and more efficient by anticipating feed depletion.

Nearby, Lumafield showed the utility of computed tomography for nondestructive testing, and discussed how its web-based software can help conserve resources. Just as CT scanners provide physicians a 3 dimensional view of anatomical structures without taking them apart, the technology can do the same for manufactured assemblies.

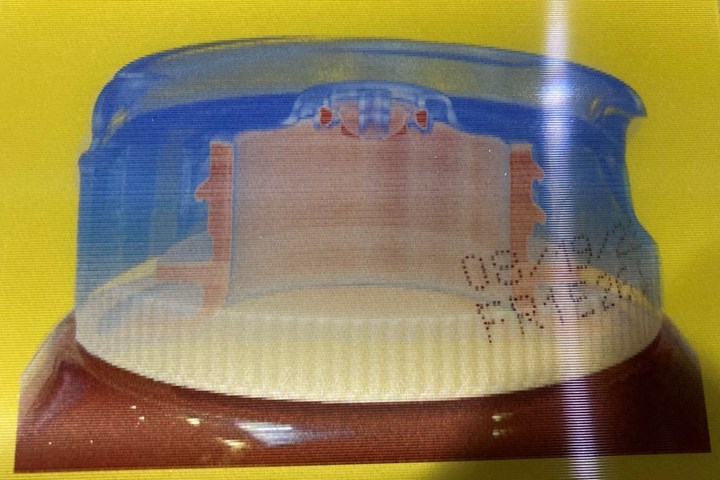

Reminiscent of Sportflics, cards distributed by Lumafield show a photo of the exterior of a bottle assembly, shifting to a CT slice of the bottle assembly with its interior structure, depending on the orientation with respect to ambient lighting.

Photo Credit: Matt Stonecash

In that same aisle, Konica Minolta demonstrated how their instrumentation and software can quantify differences in color of plastic samples, providing quality control with valuable information on when and how a color package needs adjustment.

Trends and Challenges in Recycling

Re-Cre8 Recycling, a distributor of reclaimed materials, discussed the challenges of sourcing and collecting waste materials for recycling, and the sometimes-related problem of recycling skepticism in the public discourse.

Avian Machinery, a manufacturer of shredders, granulators, washing lines, and agglomerators, raised the topic of an oft-overlooked class of single use plastics: the ones we are all wearing. The recycling of textile fibers surely must have an important part to play in the movement towards circularity.

BritAS Recycling Solutions, supplier of screen changers and melt filters, remarked upon customer interest in finer and finer screens. Recyclers are striving for higher quality and purity output to sell into higher-value applications, applications where impurities are not just unsightly but can cause mechanical weak points.

These limited highlights only illustrate the variety of discoveries to be made in the expo hall. Every exhibitor, each demonstration, every speaker made their own contribution to the richness of the experience. As a student of the industry I am indebted to all.

Related Content

-

Video: Ultradent Bags Both Hot Shots Prizes at PTXPO 2023

Topping five other entries in voting by fellow molders, the Ultradent team talks about their Hot Shots sweep.

-

What Stories Would Your Most Challenging Injection Molded Part Tell?

Time is running out to enter Plastics Technology’s Hot Shot’s Injection Molded Parts Competition — share your company’s capabilities via its greatest molding challenges.

-

Movacolor PTXPO Spotlight

Movacolor discusses the upcoming Plastics Technology Expo (PTXPO) March 28-30