technology in action

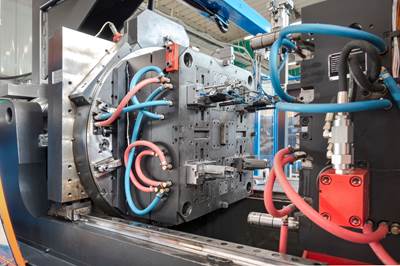

Secondary Injection Unit Provides Primary Benefits for Molder

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Tony Deligio

Editor-in-Chief, Plastics Technology

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

Read MoreNew CRM Streamlines Quoting for Automotive Molder

Eliminating the need to contact each supplier for every individual quote, a new CRM for automotive supplier Axiom Group tracks past quotes as well as industry history to generate fast, reliable RFQs and more.

Read MoreNovel ‘Clamtainer’ Extends Thermoformer's Reach in Packaging

Uniquely secure latching expands applications for Jamestown Plastics’ patented clamshell package design.

Read MoreAs Currier Grows in Medical Consumables, Blow Molding Is Its ‘Foot in the Door’

Currier Plastics has added substantial capacity recently in both injection and blow molding for medical/pharmaceutical products, including several machines to occupy a new, large clean room.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Tony Deligio

Editor-in-Chief, Plastics Technology

Warpage Waylaid Via Simulation

Designed to form a component that would hold headlights in place, the mold was intended to produce a front-end automobile bracket. Instead of parts however, the tool’s real output was problems.

Read More‘Get the Right Information to the Right People at the Right Time’

Scott Rogers at Noble Plastics is working on production-monitoring software to empower his shop-floor personnel.

Read MoreYoung Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

Read MoreFaster, Fail-Safe Mold Changes with Multicoupling Hose System

Wirthwein Medical cut mold setup times in half, thanks to Hasco’s new multicoupling system for cooling lines.

Read MoreDeDuster Systems Cleans Up rPET Sheet

rPlanet cut its gel count drastically—allowing it to sell more sheet at prime prices—after installing a DeDuster system.

Read MoreVacuum System Gives Molds a Chance to Vent

When the in-house vacuum systems and tooling tricks that NMC Dynaplas usually deploys to deal with trapped gas failed, it turned to a Mold-Vac system and saw reject rates go from 44% to zero.

Read MoreCustom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Tony Deligio

Editor-in-Chief, Plastics Technology

LFT-D Thrives in Automotive and Other Durables

Teijin Automotive acquires its 10th direct long-fiber thermoplastic system as demand for this technology soars.

Read MoreCaptive Molder Goes AM Route for Short-Run Project

Pivoting from injection molding to additive manufacturing helped a maker of automotive wire routers save about $1 million in project costs and eight weeks of lead time.

Read MoreNozzle Shutoff Shuts Down Drool

A machine-nozzle shutoff device helped Klein Tools cut drool from 24 lb/day to just 2.1 lb, with the remaining drool coming from the hot runner, not the machine.

Read MoreFour-Way Collaboration Yields Lighter Pharma Bottles with Better Barrier

Alltrista combined innovations in processing and materials for a competitive launch into a new business sector.

Read MoreMedical Molder Boasts Showpiece Material-Handling System

Flex Manchester is so proud of its new, elaborate drying/conveying system that it greets visitors front and center on their way to view the cleanroom molding floor.

Read MoreMolder Eliminates Line Blowouts with Deflection Elbow

Parker Chomerics eliminated chronic elbow failures since switching to Hammertek conveying elbow more than two-and-a-half years ago.

Read MoreInjection Molder Changes Up Color Changes

An injection molder of trash cans, pallets, totes and other plus-size components, Rehrig Pacific’s machine fleet is composed of larger tonnage presses whose size makes material changes at the feed throat a potentially dizzying exercise.

Tony Deligio

Editor-in-Chief, Plastics Technology

ERP Platform Keeps Molders Connected in the Pandemic

Enterprise resource planning (ERP) software offers its users many tools and modules with manufacturing and plastics specific platforms like DELMIAworks touching everything from inventory and quality to bookkeeping and process and machine monitoring.

Read MoreOvermolding Overhaul

An articulating mold and versatile auxiliary injection unit helped this molder rethink its tried-and-true approach to insert molding.

Read MoreBetting Big on Recycled PET

Distributor of virgin PET resins PolyQuest is also a growing manufacturer of recycled PET resins.

Read MoreFilm Processor Boosts Line Performance with Air-Ring Retrofit

Air-ring upgrade results in output gains up to 23% for leading film processor in Indonesia. Gauge uniformity also improved.

Read MoreIsraeli Pipe Processor Adds Potent Single-Screw Extruder

Billed as ideal for large-diam. pipes, new extruder provides processor with higher output and better quality while consuming less power.

Read MoreDespite COVID-19, ERP Software Keeps Molder Working—Even from Home

ERP platform’s remote access, real-time operations overview, and transparency into production output and customer demand help custom molder weather coronavirus.

Read More