DeDuster Systems Cleans Up rPET Sheet

rPlanet cut its gel count drastically—allowing it to sell more sheet at prime prices—after installing a DeDuster system.

Gels were not on rPlanet Earth’s radar when the vertically integrated rPET processor started up back in 2018. Under one roof at its 300,000+ ft2 plant in Vernon, Calif., rPlanet takes in bottles, clamshell containers, and other packaging waste from curbside collection; puts it through an extensive series of sorting and cleaning procedures; grinds it into flake and subjects it to rigorous washing and decontamination; raises the intrinsic viscosity (IV) of the material in accordance with end-use requirements; and processes it into food-grade sheet, thermoformed containers, and injection molded preforms for bottles.

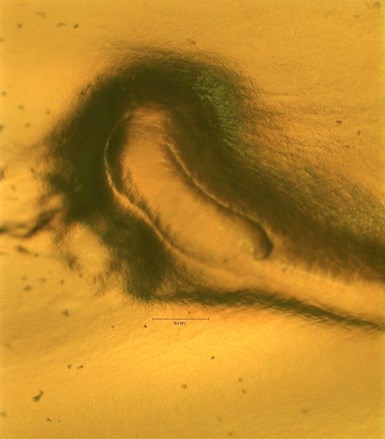

But those nasty gels became an issue in rPlanet’s extruded sheet soon after the plant was started. Gels are visual defects that can be caused by a variety of factors. No one wants gels, so quality-control departments are trained to be on the lookout for them. They use industry-standard references to manually count gels, or expensive automated machines that can count them automatically. Rolls of sheet with out-of-spec gel counts are sold at a significantly discounted rate, or must be ground up for reuse, which hurts the bottom line.

Gels are a common problem often caused by dusty, contaminated materials and the defects they cause can negatively impact the price a sheet processor can demand for its product. Photos: Pelletron Corp.

While gels can be caused by several different things, dust and other fine contaminates are high on the list. Recycled bottle flake is notoriously dusty because of the mechanical attrition inflicted during grinding, decontamination and the numerous material-handling steps that occur between the baled post-consumer bottles and the extrusion or injection molding machine.

So after discovering that gels were creating quality issues, rPlanet Earth decided to do something about it and contacted Pelletron Corp., Lancaster, Pa. Pelletron specializes in gentle pneumatic conveying and DeDuster systems for plastic processing. Pelletron was familiar with rPlanet’s operation because it had supplied rPlanet with its entire material-handling system from the wash line to the extruder and injection machines.

The Pelletron DeDuster systems use an electromagnetic flux-field coil to disturb fine dust stuck to the flake due to static electricity, along with counterflow air to separate dust and streamers from the flake. These systems can lower the dust content from over 2000 ppm concentration of particles up to 500-micron size to less than 200 ppm. Other dust-removal systems on the market cannot achieve that level of separation in a package as compact as the DeDuster, Pelletron maintains.

So rPlanet Earth purchased an XP45 DeDuster capable of handling 4410 lb/hr of rPET flake for each of its Welex-brand sheet lines, recalls Mac Schlicher, rPlanet Earth’s sr. process engineer. The low stack-up height of the DeDuster allowed it to be mounted atop the extruder throat, below the loss-in-weight feeders. Pelletron supplied the equipment and controls while rPlanet handled the electrical and mechanical installation.

The low stack-up height of Pelletron’s DeDuster allowed it to be mounted atop the extruder throat, below the feeders.

The DeDusters did the trick; Schlicher says the incidence of gels diminished after the they were commissioned on the sheet extrusion lines. In a controlled study on one line, up to an average of one gel (0.2-1.0 mm²) was counted for every meter (3.28 ft) of sheet extruded when the DeDuster was off. That count made the sheet off-spec for rPlanet’s more persnickety customers. Turning the DeDuster on reduced the gel count to an average of 0.17 gels in the same size range per meter of sheet. That was on spec, meaning the sheet could be sold at prime rate.

Pelletron’s DeDuster systems are available in capacities from 50 to 330,000 lb/hr. The company offers free testing to demonstrate how well the unit can clean a particular material.

Related Content

Brewer Chooses Quick-Change Flexibility to Blow Wide Range of PET Beer Bottles

Beermaster Brewery found a “universal” stretch-blow machine from PET Technologies enables multiple changes per day among four sizes of beer bottles.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreExtrusion Excellence: This Year's Top Stories

Revisit the year’s most popular articles on extrusion technology and processes, showcasing innovations, best practices, and the trends that captured the plastics processing community’s attention.

Read MoreHow to Decrease the Extrudate Temperature in Single-Screw Extruders

In many cases, decreasing the discharge temperature will improve product quality and perhaps even boost rate. Here are ways to do it.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More