Four-Way Collaboration Yields Lighter Pharma Bottles with Better Barrier

Alltrista combined innovations in processing and materials for a competitive launch into a new business sector.

A three-year development program launched three sizes of OTC pain-reliever bottles that utilize a combination of novel machinery, resin and additive to trim an average of 20% on bottle weight while retaining equal or better MVTR.

A joint development effort involving a blow molder and suppliers of resin, additive and machinery produced a family of pharmaceutical bottles with 15-20% weight reduction and up to 35% lower moisture vapor transmission rate (MVTR). For the molder, Alltrista Plastics, this combined advance in sustainability and bottle performance has been the gateway into a major new business area.

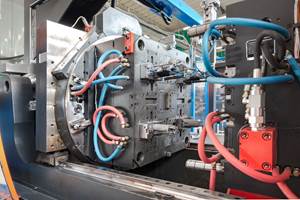

The molder (formerly known as Jarden Plastic Solutions) is based in Greenville, S.C., but also has plants in Springfield, Mo., and Reedsville, Pa., as well as in Puerto Rico and the UK, with around 1000 employees in total. Its core business is in medical products, but around five years ago, the company decided to expand into pharmaceutical packaging. It did so in a rather ambitious way, by adopting a novel blow molding technology exclusive to the Italian company SACMI and called Compression Blow Forming (CBF). In that process, a single machine extrudes a “hockey-puck” blank of plastic, which is sliced off and placed in a compression mold on a rotary wheel to form the threads and then stretch-blow molded (full details here). These machines can process HDPE, PS and PET at up to 12,000 bottles/hr.

According to SACMI, Alltrista has become the world’s largest user of CBF technology—with eight machines of 16 and 20 stations and more on order. The reason is explained by Mike Castillo, Alltrista’s director of rigid packaging: Compared with injection-blow molding (IBM), the elimination of a hot-runner system in CBF allows for weight reduction and more uniform material distribution. “CBF addresses the particularly challenging areas of the bottle threads and base, where material is concentrated,” he explains. SACMI also notes that CBF allows lower melt temperatures and eliminates the shear of the injection molding phase of IBM, both of which are favorable for high-molecular-weight resins.

Combining weight savings and performance not achievable with standard blow molding machines and HDPE resins.

This factor came in handy for Alltrista’s first major pharma bottle project, started five years ago. It brought in two other partners besides SACMI. Dow Packaging & Specialty Plastics contributed a new bimodal HDPE, Continuum DMDD-6620 Health+, with 0.958 density and 27 MI. This resin, together with a special nucleator additive called UltraGuard from Milliken Chemical, boasts 43% lower MVTR than standard HDPEs, according to Dow. That additive, supplied in masterbatch form, causes the normal random distribution of crystalline blocks within the Dow HDPE to align like bricks in a wall, creating a “tortuous path” for water molecules to thread their way through, and resulting in a 20-60% reduction in transmission rate of moisture, O2, CO2 and solvents, Milliken says. Subsequently, Dow launched Continuum DMDE-6620 Health+, already containing UltraGuard to eliminate the need to blend at the press.

All this came together two years ago with the launch of three sizes of bottles (15, 18 and 25 ml) for Advil ibuprofen tablets from GlaxoSmithKline. Across the range of sizes, Alltrista’s bottles made by CBF with the new resin/additive system average 20% weight reduction versus previous IBM versions and maintained “equal or better” MVTR, Castillo says. He attributes the weight savings to CBF and the resin/additive system in a roughly 60/40 proportion. The current program envisions production of more than 80 million Advil bottles annually.

That success was just the start for Alltrista’s new pharma packaging business. Since then, it has produced a 90-cc HDPE bottle for another customer with a 15% weight reduction, saving 350,000 lb on annual production of 100 million bottles. Alltrista is also launching a line of Allstock stock pharma bottles and closures in 11 sizes of 50 to 500 ml. These will use a standard pharma HDPE resin. Using CBF, Alltrista’s goal is to save 2.8 million lb/yr on the bottles plus an additional 3.5 million lb/yr on the caps through a proprietary redesign. If a customer has need for extra barrier afforded by the Dow/Milliken material system, Castillo says, this can be achieved. For example, a 100-ml bottle can attain 15% weight reduction plus 35% lower MVTR.

Castillo notes that many brand owners and packaging companies are looking for improved sustainability. One route is to incorporate post-consumer recycle (PCR), but that imposes a substantial regulatory burden of expensive and time-consuming testing. “You can’t get there overnight—it could take five years.” While not free of regulatory expenses, lightweighting through process, material and tooling solutions is a much faster route to the same end.

Related Content

Custom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreRead Next

Firms Collaborate on 'Sustainable' HDPE Pharma Bottle

Milliken, SACMI, and Jarden Plastics combine on HDPE bottles that reduce plastic and energy use.

Read MoreCompression Blow Forming Process in Commercial Production

Expectations of higher productivity, improved quality, and energy savings for a novel blow molding process are now being realized in commercial production at Amcor Rigid Plastics in Youngsville, N.C.

Read MoreCompression Blow Forming: Promising New Process

‘Game-changing’ technology is overcoming initial growing pains with a new generation of machines.

Read More