How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Dark-to-light color changes on hot-runner systems can be time-consuming and costly for molders. Excessive downtime and scrap during color changes cut into processors’ profit margins and can make them less competitive. Thermal-gate (hot-tip) designs in hot-runner systems are common and can be unusually difficult to clean, depending on the tip design. Here I’ll discuss methods to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Fig. 1: Dark-to-light color changes can be problematic because of the possibility that the dark color could contaminate the lighter-colored part.

An injection molder’s top priority is to achieve the highest possible productivity while utilizing the least amount of capital. Dark-to-light color changes can be problematic because of the possibility that the dark color could contaminate the lighter colored part (see Fig. 1). In many situations the streaking’s origin is in the hot-runner system. That system is a complicated piece of tooling that on occasion allows for dead spots where color hangs up. The goal for injection molders is to be able to clean these dead spots quickly and efficiently.

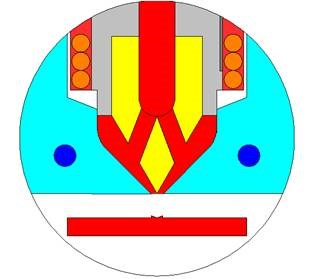

Fig. 2: Thermal gating or hot-tip gating generally represents a more economical mold investment than valve gating. The thermal gate forms a small, solidified, cold plastic slug (or bubble) inside the gate bore during the cooling time of the part.

Thermal gating or hot-tip gating generally represents a more economical mold investment than valve gating. The thermal gate (see Fig. 2) forms a small, solidified plastic slug (or bubble) inside the gate bore during the cooling time of the plastic part. This cold slug remains in the gate during the mold-open step, part ejection, and mold-close motion. With the next injection, the pressurized melt flushes the cold slug into the melt stream that fills the empty cavity. While all molding parameters (pressure, temperature, and time) are focused on producing a high-quality plastic part, they are also responsible for the formation of the cold slug at every cycle to avoid drooling and stringing at the gate.

The issue with purging a thermal-gate system is removing the color from the bubble at the gate of the hot-runner system. The larger the bubble, the more difficult it is to clean. The color in a smaller bubble may be removed by raising the hot-runner tip temperatures by 100° F and using a commercial purging compound to clean the machine. However, if the bubble is large, it will be impossible to remove the color without further action.

One way to counter large bubbles in the gate is to install thermoset inserts in the gate area. The inserts will reduce the size of the bubble, making it easier for the purging compound to remove the dark color. Raising the temperature of the hot-runner tip will also assist with the removal of the color. Most hot-runner manufacturers offer thermoset inserts as an option to their customers.

Fig. 3: Molders that have thermal-gate hot runners but no tip insulators should purge the machine and then remove the cavity plate. After the cavity plate is removed, and time has been allowed for the tips to cool, each plastic bubble will have to be removed manually.

Molders that have thermal-gate hot runners but no tip insulators will have to use a different approach for cleaning and maintaining the hot-runner system. The best solution for this scenario is to purge the machine and then remove the cavity plate. After that plate is removed, and time has been allowed for the tips to cool, each plastic bubble will have to be removed manually (Fig. 3). After all the bubbles are removed, the cavity plate may be replaced and then natural-color resin is run through the machine.

As a result, the bubble will become natural resin and make color changes easier because no dark color will be present in the gate. Using the purging compound after this task has been complete will be sufficient for for dark-to-light color changes.

About the Author

At the time of publication, Andrew Reeder serves as the North American sales manager for Thermoplastics at Chem-Trend, located in Howell, Michigan. Chem-Trend specializes in manufacturing purge compounds (Ultra Purge), release agents and other chemical specialties. With two decades of expertise, Andrew has been aiding companies within the plastic industry to decrease their purging expenses through the utilization of Ultra Purge. Contact: 810-852-1000

Related Content

How to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreHow To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

Read MoreHow to Design Three-Plate Molds: Part 2

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More