'Chaotic Advection' Creates New Polymer Blend Morphologies

A continuous blending device called the SmartBlender is creating polymer blends with novel properties by folding the two melts together, rather than distributing one evenly throughout the other.

A continuous blending device called the SmartBlender is creating polymer blends with novel properties by folding the two melts together, rather than distributing one evenly throughout the other. Developed by the Dept. of Mechanical Engineering at Clemson University in Clemson, S.C., with National Science Foundation support, the SmartBlender uses a principle of fluid dynamics known as chaotic advection to fold a masterbatch or other component into a matrix polymer. Layering or folding materials together forms a variety of controlled and repeatable polymer morphologies—from layers, ribbons, and platelets to spongy interpenetrating structures. Unusual properties are said to result.

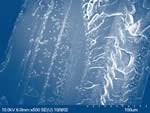

Among these novelties is “directional conductivity,” in which blends of LLDPE with a carbon-black masterbatch show electrical conductivity in the machine direction, but not the transverse direction, when extruded into film, sheet, tube, or rods. Chaotic advection creates linear striations of carbon black particles in the machine direction, which act like tiny wires. The striations can also be cross-connected to give conductivity in the transverse direction or through the film thickness. Computer simulations show that these striations are really spirals with projecting filaments, the spirals being arranged parallel to the axis of the SmartBlender, says Clemson Prof. Dave Zumbrunnen.

Clemson’s striated blends reportedly achieve a much higher level of conductivity with less carbon black than do conventional compounds. Tests reportedly show that as little as 0.5 wt% carbon black mixed via chaotic advection can achieve a level of conductivity comparable to about 3% carbon black with conventional twin-screw compounding. Because a twin-screw disperses additives evenly, it takes a lot more carbon black for the particles to be close enough to touch each other and create a continuous electrical path.

Interpenetrating blends

Clemson has also produced interpenetrating blends of immiscible polymers, like a combination of PP and LDPE. Chaotic advection produces “novel morphologies such as sponge-like blends, over broader compositional ranges than are achievable with conventional compounding equipment,” says Zumbrunnen. Tests combined 20-MFI PP with 30% by volume of 12-MI LDPE; the result was spongy, mechanically interlocked morphologies that have the potential to improve PP’s normally poor cold impact strength and ESCR, he says.

Chaotic advection creates the spongy morphologies by stretching and folding thinner and thinner layers of LDPE in the PP matrix. After re peated layering, the LDPE layers become so thin they eventually rupture, letting the PP flow through the holes in the LDPE. Holes also form in the PP layers, creating a fibrous spongy structure out of the stiffer PP. This transformation has been observed experimentally and also in computer simulations. Other potential applications for chaotic advection include materials with improved tensile and barrier properties and selective permeability, Zumbrunnen says.

How it works

The SmartBlender is fed by two 0.75-in.-diam. single-screw extruders, each of which has a metering pump to give precise control of the ingredient ratio. The two melt streams enter a crosshead die from opposite sides, then pass into a distribution head. The matrix material passes through a single central port, while the secondary resin or masterbatch goes through nine small ports arranged in a circle around the central one.

From the distribution head, the material enters the cylindrical blending chamber, which is round at both ends and oval in the middle and externally heated with multiple zones. The chamber contains two 22-mm-diam. stirring rods, which are slightly offset (15 mm) from the chamber’s central axis. The rods are turned independently by stepper motors with computer control of the direction, speed, and number of rotations.

According to one mixing recipe, the rods corotate, but one of them spins three times faster than the other for a specific number of turns. Then it slows down and the opposite rod turns faster for a specific number of turns. Changing the rod rotation protocol can produce blends of differing morphologies without any equipment modification.

Chaotic advection theories were first explored and articulated by Prof. Hassan Aref at Virginia Tech. in the mid 1980s. Clemson’s work related the principles to plastics and led to patents that are pending on the first batch and continuous processes.

At least one machine supplier has been selected to produce commercial- scale equipment, and more such agreements are expected. “We’re now doing developmental plastics for specific companies,” Zumbrunnen says, “extruding these materials into film and sheet for companies to test in their own labs.”

Related Content

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More