Convert PVC Pipe Dies to Make Fence Profiles

If you are a PVC pipe extruder who wants to get into the burgeoning market for fence profiles, you have several new options from American Maplan.

If you are a PVC pipe extruder who wants to get into the burgeoning market for fence profiles, you have several new options from American Maplan. The company offers different ways to morph a round profile into a square, depending on what kind of equipment you have and how much you want to spend to convert it.

One or two spiders?

Maplan’s approach to converting dual- and single-spider dies leaves the spider body in place and replaces the round pipe pin and bushing with a longer transition piece. The latter starts out round at the upstream end and finishes with a square pin, bushing, and calibrator.

Maplan’s RK-model fence adapters are designed for retrofit to older pipe extruders with single-spider dies. These adapters range from 0.5 in. up to 36 in. diam.

RD-model fence adapters are for more modern, high-throughput, dual-spider dies. RD adapters provide better wall control and go up to larger sizes (0.5 to 48 in.). RD adapter dies use newly introduced adjustable bolts in the last ring before the orifice. Maplan says these ad justable bolts can put 0.012-in.-thick capstock over fence profiles with ±0.004 in. accuracy, even around corners. Fence capstock is typically run 15-20 mm thick in order to guarantee at least 8 mm on the corners, according to Maplan sources.

Doing the ‘taffy thing’

A more novel way to square a circle leaves the pipe die in place and pulls the soft, warm pipe profile into a square shape by stretching it over a nylon preformer (see above, right). The profile then goes into a square vacuum sleeve and vacuum cooling tank.

Maplan has also developed a way to adapt a calibration system so that a standard pipe vacuum tank can accept a square or rectangular profile. This system can drop into any round Maplan tank and can be adapted to fit competitors’ pipe tanks as well.

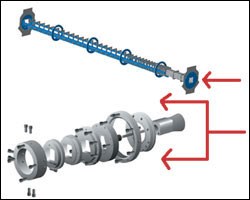

Maplan will install the conversion, which consists of a row of about 72 square templates in a rack. The rack is welded in place and allows quick profile changes by simply dropping in different templates (see left).

A 250-mm-diam. vacuum tank for 250-mm OD pipe can be converted to one for 5 x 5 or 2 x 8 in. fence profiles. Smaller pipe tanks can be converted for 1 x 1 up to 3.5 x 3.5 in. accessory profiles. Best of all, the conversion is reversible. If the rack is removed, the tank can produce pipe again.

Converting a pipe tank costs about $85,000, half the cost of a standard profile calibration system for single or dual downstream profiles.

Related Content

-

Reduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

-

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.