Custom Molders Had Strong 2012

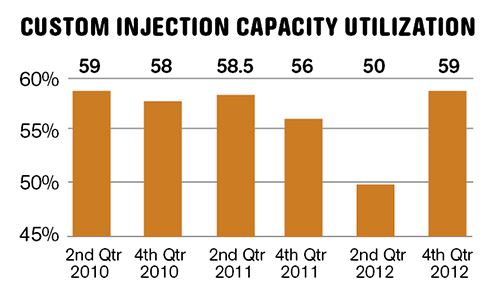

Custom injection molders’ capacity utilization jumped almost 9 percentage points from mid-year to December 2012, hitting an average of 59%, back to the high levels of 2010 and the first half of 2011.

Custom injection molders’ capacity utilization jumped almost 9 percentage points from mid-year to December 2012, hitting an average of 59%, back to the high levels of 2010 and the first half of 2011.

In our latest half-year survey, with 75 plants responding, 35% saw higher capacity utilization in the second half of last year, about the same as in the first half, while 45% saw lower utilization, and 20% reported no change.

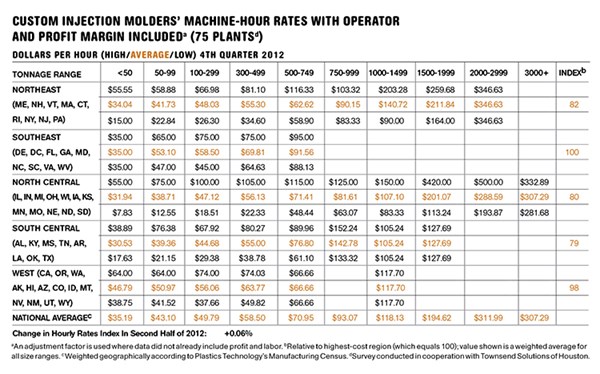

Our index of custom molders’ machine-hour rates showed no change in the half-year period, after a 1.5% increase in the first half. That was less than the 1.9% cumulative growth in the index for 2011.

A whopping two-thirds of respondents expressed optimism that business conditions would improve in the near term (a 50% increase over the first half), vs. 11% predicting worse conditions, and 23% foreseeing no change. Optimists outnumbered pessimists by more than 6:1, almost twice the ratio in the first half. In the Northeast, Southeast, and South Central regions, at least 75% of the respondents expressed optimism about business conditions. Optimism was considerably weaker among molders in the North Central and Western regions.

Among 41 mold shops reporting, the average increase in new orders was up 2.6%, vs. 2% in the first half.

Related Content

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

Is There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.