Delivering Increased Benefits to Greenhouse Films

Sponsored ContentBaystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Share

Polyethylene (PE) films are commonly used in agricultural applications for many different purposes. They bring advantages to food production by helping increase crop yields, protecting crops from adverse conditions and reducing the need for water and chemicals in the production process.

There are several different agricultural applications where PE films have an advantage, and today Baystar is focused on bringing Borstar performance resins to greenhouse films used in crop production. This is an area that is expected to see continued growth between now and 2028.

Advantages of greenhouse films

Borstar technology delivers unique advantages to greenhouse film applications due to its unique molecular architecture. Borstar technology relies on a broad bimodal molecular weight distribution of polyethylene copolymers to enhance performance and processability of material, making a film that is readily processed on film equipment and mechanically strong and tough to provide enhanced crop protection.

These variables grant engineers and product development technicians significant design freedom to create products over a wide density and molecular weight range, allowing for precise performance of the material for a particular application.

Borstar resin provides better durability with increased toughness, environmental stress crack resistance (ESCR) and weatherability. Because of the improved processability and mechanical properties of Borstar resins, demanding agricultural applications can gain from a longer service life of the film, reducing the total carbon footprint of the entire agricultural operation.

Additionally, the unique optical properties of Borstar, which are also derived from its molecular design, bring a natural ability to diffuse light while maintaining high transmission rates. The matte appearance of the film naturally diffuses sunlight across the interior of the greenhouse and does not tend to reflect light the way a clear film would. This performance is achieved without the use of additional fillers or other additives to diffuse or absorb the light. This design allows the maximum use of sunlight for the plants in the greenhouse without overexposing them and keeping the climate within control limits to improve crop yield and quality.

Good light distribution in the greenhouse allows the crops better conditions for photosynthesis and microclimate development. Additionally, the PE film and greenhouse structure protect from too much direct sunlight, high winds, extreme temperatures and variable rainfall. These types of greenhouse films are suitable for crops such as vegetables (including non-native varieties- tomatoes, cucumbers, peppers), lettuce, melons, flowers and other crops that thrive under consistent conditions.

This design allows the maximum use of sunlight for the plants in the greenhouse without overexposing them and keeping the climate within control limits to improve crop yield and quality.

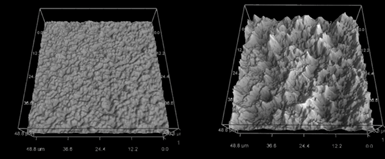

Borstar FB2230 was evaluated for the agricultural film greenhouse application owing to its physical and optical properties. Because of the unique molecular structure, a naturally matte surface finish occurs when making blown film (Figure 1).

Figure 1: Unique molecular structure creates naturally matte surface finish.

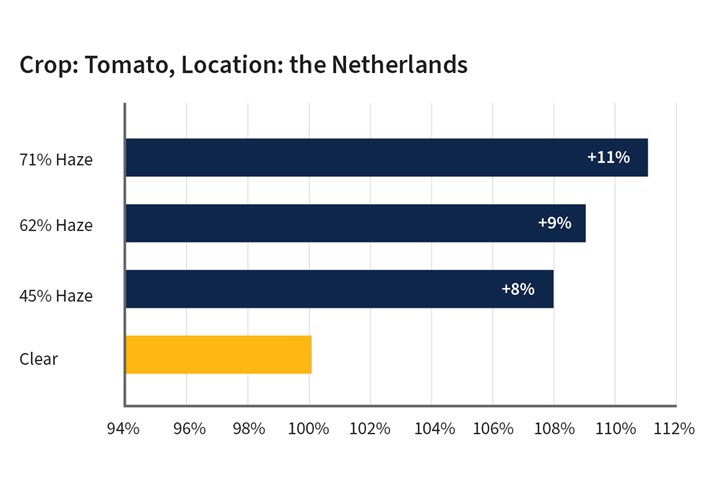

This matte surface finish is what allows even distribution of the light which was shown to improve crop yields in a study of tomato growth in the Netherlands1. Compared to a clear control film, a moderately hazy film (45% haze) showed an 8% increase in crop yield. When the haze value was increased from 45% to 71%, a further 3% increase in crop yield was seen (Figure 2).

Figure 2: Crop yield improvements with Borstar.

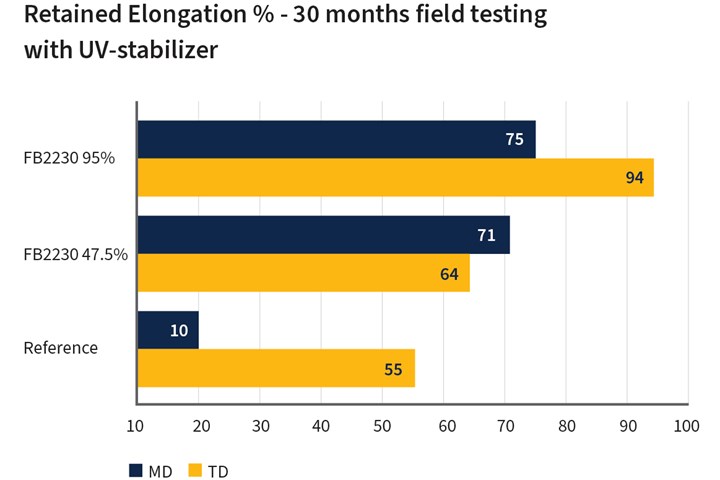

While the production advantage of crops is clear from the use of Borstar film, it is also essential that the film be able to hold up mechanically to use in the field. While durability can be improved by using thicker films, 3-4 mil film is typical for single-season growing while 6-10 mil film is more common for multiseason use, the addition of UV stabilizers can also bring increased longevity and durability to the film as well. By including a UV stabilizer in the Borstar FB2230 film, the retained elongation over 30 months was improved from just 10% in the MD reference, to over 70% in the modified film examples (Figure 3)2.

Figure 3: UV stabilizers improve life of film.

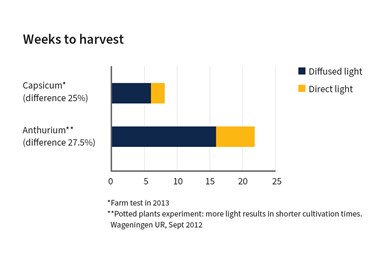

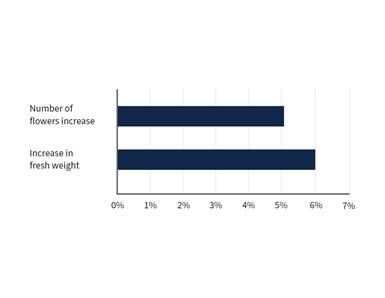

In other studies, growth acceleration and production increases were also measured. By using a film that diffuses light, the time to harvest for different plants was reduced by about 25% while increasing the total weight of finished product by about 6% (Figure 4). These kinds of improvements in agricultural operation allow for increasing the value per square foot of farmland and bringing better, more reliable production methods to the market.

It is clear that these kinds of improvements in agricultural operation allow for increasing the value per square foot of farmland and bringing better, more reliable production methods to the market.

Figure 4: Harvest time is reduced with Borstar film usage.

Conclusion:

Several case studies have shown how the advanced optical and mechanical properties of Borstar films can significantly benefit agricultural and greenhouse applications. Increases in yields, decreases in production time and ease of use and durability are all inherent advantages of this technology.

Products like Borstar FB2230 are well positioned to serve this growing market segment and to continue to bring performance to a demanding application that is critical to our modern supply chain infrastructure. PE resins with unique and tailorable molecular designs for demanding applications continue to push the boundaries of what is possible and help deliver efficient and effective solutions to the market.

[1] Diffuus licht bij tomaat, Wageningen University and Research Glastuinbouw, 2012 (Rapporten GTB 1158)

[2] "Effect of a Diffuse Glass Greenhouse Cover on Rose Production and Quality" N. García Victoria, F.L.K. Kempkes, P. Van Weel, C. Stanghellini, T.A. Dueck and M. Bruins, Wageningen UR Proceedings of the International Symposium on Advanced Technology

Susan Zhang is Senior Technical Service and Development Advisor. Peter Malmros is the Business Development Manager. Kyle Anderson, Ph.D, is Application Development Supervisor.

All text, charts and images are copyright Baystar.