Die Drawing Makes ‘Plastic Steel’From Wood-Filled PP

A developer of new plastics technologies is applying low-temperature die drawing to take advantage of a new raw material: expanded, oriented, wood-filled polypropylene (EOW-PP).

A developer of new plastics technologies is applying low-temperature die drawing to take advantage of a new raw material: expanded, oriented, wood-filled polypropylene (EOW-PP). It looks and feels almost indistinguishable from natural wood but is 150% stronger. It’s also 300% stronger than ordinary PP and close enough to the strength of steel that the term “plastic steel” is no great exaggeration.

“We haven’t been able to break it yet. It just bends,” says Frank Maine, president of SHW (Synthetic Hardwood) Technologies Inc. in Guelph, Ont., the developer of EOW-PP.

This unusual new material is made by a combination of two metalworking processes: solid-state extrusion and die drawing. Solid-state deformation processes like ram extrusion are typically used to shape high-value, non-melting plastics like UHMW polyethylene and PTFE into tubes and sheets, not to form inexpensive commodity resins. Orienting of PP film and fiber is commonplace, but orienting a solid PP profile has been limited to lab work in a few universities.

Squeeze billets into rods

In the early 1990s, researchers at the Aluminum Company of Canada Ltd. (Alcan) in Kingston, Ont., spent six years ram extruding unmelted PP into highly oriented rods of enormous strength. The process requires two steps. First, PP is extruded conventionally into billets—solid, round, or rectangular profiles that are cut to 15-20 in. lengths. The billets are then heated to slightly below the melting point and are ram extruded with a very high draw ratio into thin profiles. Haul-off tension around 450 psi keeps the profiles from relaxing before they cool.

Alcan patented the process and material but halted the project after the price of aluminum plunged. Symplastics Ltd. in Orangeville, Ont., a plastics processor already experienced in deformation processing of UHMW-PE sheet, bought Alcan’s patents and lab line and spent three more years of R&D on the process.

After three years, Symplastics’ only commercial success with the OPP profiles were small rods made for Frank Maine, who machined them into unbreakable drumsticks for musicians. “Drummers objected to the look of the plastic,” Maine recalls. “They liked the performance of the PP drumsticks, but wanted the sticks to look like wood.”

So Symplastics added 8% wood flour to the billets, which made the rods look and feel remarkably like wood. Wood-filled rods acquired less orientation but still had impressive strength. Eventually Symplastics found the R&D too costly and sold the patents and lab line to Maine, who set up SHW to try to commercialize more applications for the super-strong material.

One such application is unfilled OPP beams for automotive side-impact bars, which were tested recently side by side with steel beams. The load at failure for OPP was 30% below that of steel. But while the steel beam snapped when it failed, the OPP beam only delaminated. These preliminary test data were released earlier this month at the Society of Automotive Engineers show in Detroit by Dr. Phillip Bates, Assoc. Prof. at the Royal Military College in Kingston, Ont.

Speeding up the process

Slowness of the process was a major problem for Alcan and Symplastics. First, billets were extruded at a glacial pace of about 4 ft/hr. Adding 30% wood flour speeded up billet extrusion to about 10 ft/hr, but that still wasn’t fast enough.

The solid-state extrusion step was somewhat faster but very energy intensive. Pushing a 15-in.-long billet of 2.75-in. diam. through a compression chamber to form a 15-ft-long, oriented rod of 0.75-in. diam. took 4 min and required 3000 psi of force.

Still the process had to go faster. What Maine tried next came from his experience in die drawing of metal wire. Maine set up an experiment to see what would happen if he grabbed the front of the billet as it emerged from the die and pulled while the ram pushed. “We were told die drawing wouldn’t work with plastic, that the profile would thin out or simply break,” Maine recalls.

It didn’t. Instead, the wood-filled plastic profile held its shape and stretched. As the polymer oriented, the profile density dropped by nearly half from 1 g/cc down to 0.52 g/cc. As the polymer chains stretched, the wood fibers lined up lengthwise and pulled away slightly from the polymer, leaving tubular voids behind each fiber. These micro-voids reduced weight, increased topload strength, and imparted the look of natural wood grain.

Die drawing also went much faster—up to 30 ft/min, vs. 4 ft/min for ram extrusion alone. At such a speed, it may be possible to run billet extrusion in line with die drawing, Maine speculates. And with die drawing, Maine doesn’t need to use the ram, thereby saving energy. Pushing the billets takes 3000 psi, but die drawing takes only 1800 lb of tension to do the same work. The ram now only pushes the first 5 in. of the billet through the die, enough for the puller to grab.

Die drawing may allow larger profiles to be oriented. Ram extrusion of unfilled PP is limited to small rods, probably not over 1 in. diam., because orientation takes place only in the resin close to the compression-chamber walls. The larger the profile, the greater the ratio of weaker, unoriented core to stronger, oriented skin. Maine speculates that die drawing of wood-filled PP may cause the orientation to be more evenly distributed across the profile.

Maine says die drawing can also speed the solid-state extrusion of unfilled PP. He has not yet tested the resulting product to ascertain the level of property improvement in unfilled material.

Looking for partners

SHW’s new low-density, wood-filled composite profiles aren’t out of the lab yet. SHW is actively seeking development partners in four areas: indoor construction (chiefly flooring), outdoor construction, automotive, and defense applications. The first area to be commercialized, Maine says, will be wood-replacement products for outdoor construction.

| DIE-DRAWN OPP PROFILES WITH & WITHOUT 30% WOOD | ||

PP Wood OPP EOW-PP* | Flex. Str., psi 7000 14,000 40,000 20,000 | Flex. Mod., psi 270,000 1,300,000 1,100,000 1,100,000 |

| *Expanded, oriented, wood-filled PP. | ||

Related Content

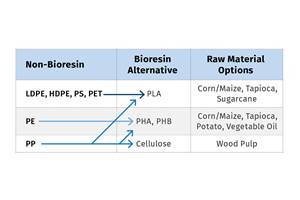

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreMaking a Play With PHA

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

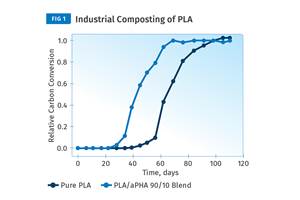

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More