Don’t Build In Melt-Temperature Variations

It’s not unusual for polymer to exit the extruder with a uniform melt temperature, only to be fouled up by downstream flow pipes and the like. Here’s how to avoid this.

Quality extrusions are judged primarily by their dimensional tolerances. Getting consistent tolerances requires steady output and uniform melt temperature throughout the extrudate. This yields uniform flow, drawdown, and shrinkage.

It’s not unusual to have a relatively uniform melt temperature leaving the extruder and/or screen changer and then have a substantial temperature difference “built into” the melt through the flow pipes and other downstream apparatus leading to the die. The longer the downstream apparatus and the lower the flow velocity, the more variation that can be built in.

In a previous column (March 2010), I discussed the degradation that can occur due to low flow velocity. The same factor can build in variation in melt temperature, which influences die-flow stability, particularly in thin cross-sections and thin coextrusion layers. These variations are often blamed on poor screw design, and operators typically respond by increasing screen-pack density. But that approach actually adds to the melt temperature, reduces the output, and offers no improvement. Sometimes it makes matters worse.

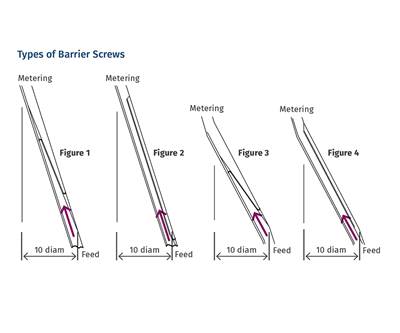

Figures 1-4 show flow velocity in a round flow orifice. The output in any area is proportional to the velocity, so what is really revealed is the variation in output across the cross-section.

Polymer flow is always laminar or layer-like because of the high viscosities, so pressure flow in a round pipe is essentially in concentric rings around the center. The highest flow always occurs in the center of the pipe, with decreasing flow velocity as the distance increases from the center. Since the polymer sticks to the walls of the orifice, the velocity is zero at the walls and maximum at the center. The hotter polymer—having a lower viscosity—moves to the geometric center of the flow area, where shear stress from the drag on the walls is minimal.

Figure 1 shows an ideal flow velocity. The flow approaches plug flow, and the velocity is pretty uniform, although still zero at the walls. This is an ideal design but cannot always be implemented for a variety of reasons. Figure 2 shows a more typical situation, where the flow orifices are oversized to control pressure or the output is reduced for other reasons. Figure 2 is what would be expected in an isothermal condition at about half the potential for plug flow.

In Fig. 3, the orifice walls are at a substantially lower temperature than the melt entering the orifice. This results in a more concentrated center flow with a higher velocity, and a larger area of the orifice filled with slower to very-slow-moving polymer. This results in a greater variation of melt temperature entering the die and is a poor operating choice. This is often a result of assuming the melt can be cooled in that way, but that either has no effect or actually increases the melt temperature because of the increased pressure drop due to the reduced flow area. Polymers are excellent insulators, and trying to cool them in laminar flow at the wall is very ineffective.

Figure 4 is a condition where the wall is at an equal or higher temperature than the melt. Any maintenance or even slight heating of the melt near the wall reduces the viscosity near the wall and the overall shear stress in the melt flow, which enlarges the flow area.

Personally, I find that setting the flow pipes and downstream apparatus 10° F higher than the melt temperature exiting the extruder is a good starting point, until more information is available. The more uniform the flow, the more consistent the melt temperature. It is important to minimize variation in temperature through the extrudate, as variation will affect the die flow and dimensions of the final part. A lot of this can often be mitigated by use of a static mixer, which should always be located as close to the die as possible so that no further variation can be built in after the mixer. Of course, proper design and thermal control of the downstream apparatus is a solution in itself that provides a narrow window where operation is near optimum.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreRead Next

Which Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.jpg;width=70;height=70;mode=crop)