Fast, Precise Machine Helps Tubing Processor Make the Cut

Instead of turning down a job or farming out cutting to another company because of downstream bottlenecks, Eagle Elastomer can now handle all extrusion process functions in-house.

The decision to send out a downstream part of the extrusion process can be a difficult one, requiring a plant manager to balance the cost of farming out the pieces and the cost of equipment that won’t be used daily.

Eagle Elastomer had been in just that situation for some time. The Cuyahoga Falls, Ohio, processor makes fluoroelastomer and perfluoroelastomer tubing for a wide range of markets. For years, they relied on the Mini Cutter from Versa Machinery Inc. for small tubing for the automobile industry. But as the need for cutting grew, the Mini Cutter couldn’t keep up because the clutch system limited the speed of cutting. Eagle Elastomer started turning down customers whose parts were too big. For projects they did take, they had to ship out some extruded material for cutting, adding an expense to customers and increasing production time while Eagle waited for the parts to return.

For this processor, the cutting phase of their extrusion process had become its Achilles heel: an older clutch cutter just wasn’t cutting it. Adam Hines, process technician at Eagle Elastomer, originally considered buying a newer model of the Versa Mini Cutter. While visiting Versa’s plant in Elkhart, Ind., to watch the newer model run, Hines noticed a larger cutter, the Versa Adaptive Cutting Technology (ACT). He asked to see what it could do, and when the Versa representative turned it on, Hines was stunned. “I couldn’t help but laugh. We were cutting 150 pieces/min, and this machine was cutting 3000,” he recalls.

While the $45,000 machine cost more than he was looking to spend, Hines knew it would allow Eagle to take on projects it previously had to turn away because the parts were too thick or big. To help convince the company’s president to invest the extra money, Hines sent a video of the ACT in action so he could see it for himself.

CUTTING TO THE CHASE

The Versa Adaptive Cutting Technologies systems were designed to take cutting online, saving storage space and valuable production time for processors like Eagle Elastomer. With a 1-, 2-, or 3-in. capacity servo extrusion cutter on a 4-in. slide base, with pinch-roll, or caterpillar servo-driven puller, the ACT systems can achieve cutting rates up to 3000 cuts/min, outpacing and out performing even the most skilled employees armed with scissors or a knife.

Now that his cutting rate is 20 times faster than his previous machine, Hines is able to slash lead times. A project that used to take a week was knocked out in a matter of hours. Customers are getting their parts faster, Hines is pushing more projects through the shop, and employees that were working on one project for a week are free to work on other jobs.

Using multiple employees for cutting requires the cost of their labor as well as the cost of other employees doing jobs that the people cutting could have been doing. The time savings adds up quickly. “Time is an asset that cannot be replaced once lost. Compound the time saved daily, and it can really add up,” Hines says.

PINPOINT PRECISION

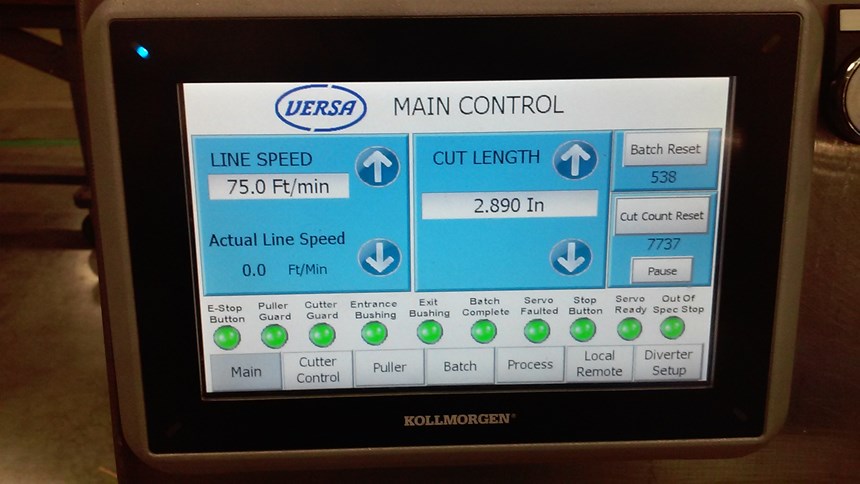

Of course, it’s one thing to cut extruded material, and another to do it accurately. ACT systems provide cutting in On-Demand mode, Cam mode, or Flywheel mode from operator input of line speed and cut length.

On-Demand mode resets the knife to a preset “home position” after every cut for maximum accuracy. Cam mode allows the machine to cut short lengths at full knife velocity without stopping, while Flywheel mode rotates the knife at a constant speed for high cutting rates. The ACT systems with Vera’s exclusive software automatically selects the best mode for each application.

Hines reports tolerances of ± 0.001 in., depending on the length and product being cut. Eagle Elastomer uses the ARPM E2 tolerances. With a product 2.5 to 4 in. diam., the machine holds ±0.007 in., with some variance allowing for tubing that compresses when cut.

The older clutch cutter couldn’t hold this level of cut-length accuracy, which led to off-spec parts and scrap. Scrap rates on the ACT machine amounted to only 0.75 lb per run, created while the machine starts and warms up and then at the end of the run as the tail passes the feeder.

EASY SETUP

The ACT also allows Hines to customize the knife speed, cut length, and line speed based on the project and save those settings in a library. Hines uses 20 to 30 stored recipes on an ongoing basis, which he says beats resetting the length and making test cuts to make sure it is correct on his old Mini Cutter for every project.

Pulling a recipe up with just a few screen touches vs. setting up each time saves time and reduces scarp parts. It took an experienced employee 15 min. to set up the old clutch-drive system for a part run, whereas anyone can find the right recipe in the library on-screen quickly and easily, guaranteeing the right settings are applied to the right part every time.

Once the correct part recipe is selected, the operator assures that cord stock or tubing has the appropriate bushing shape and size so the part doesn’t move. After that, the machine takes care of the cutting by itself. A lubrication system automatically cools and lubricates the blade to prevent overheating and ensure accuracy throughout longer runs.

A touchscreen interface with built-in length and batch control allows operators to control the cut output. Eagle has FACTS controllers on other equipment in the shop, and the ACT’s screen is similar, making it easy to figure out for even untrained employees. In over a year of use, Hines has never had to look at the manual to figure out a problem.

SIZE DOESN’T MATTER

Hines winces at the memory of farming out—or worse, turning away—projects because the material they needed to cut was too thick. Now, Hines accepts anything that comes through the door. Most of Eagle’s projects are 70 durometer, but some cord projects are up to 90 durometer. The biggest project was ¾-in. solid, and the ACT cut through it with ease, he says.

The key to tackling big projects with the ACT is the ability to change the blade sizes, Hines notes. The regular cutting blade might not be able to handle ¾-in. diam. solid rubber cord, but a stainless-steel blade has no problem. Hines even had Versa make him a custom blade that was twice the thickness of the standard blade. With the thicker blade, the ACT can cut through 2-in. diam. pieces. Since the blades are lubricated and cleaned while cutting, they last for quite a while. Changing the blades is said to be a simple and safe process.

With tubing cuts, the blade can last a year, or tens of thousands of cuts in Hines’ experience. Thicker materials and solid parts require the stainless blades, which last even longer.

Eagle’s longer runs, with upwards of 40,000 parts, used to take days. Now a long run takes hours, and with a fraction of the previous labor requirement. “There is rarely any project where we go into a second day unless it’s a gargantuan run,” notes Hines. He says the ACT machine paid for itself within the first 16 months.

Related Content

Why Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRead Next

Downstream System ‘Rewrites the Rules’ for Medical Tubing Extrusion

Extrusion downstream expert Bob Bessemer joins Novatec to enter medical tubing market with innovative line of tanks and puller/cutters.

Read MoreA Culture Built on Innovation in Medical Tubing Extrusion

Microspec was born out of innovation, and 28 years later continues to set the global standard in medical tubing by developing high-precision multi-lumen catheters—among other tubing products—by refusing to believe “it can’t be done.”

Read MoreProcessing/Workplace Safety Tips for Fluoropolymer Medical Tubing

Here's what you need to know and running these emerging materials for medical tubing.

Read More