How to Extrude Copolyester TPE Film

From building construction to medical supplies to food packaging, copolyester thermoplastic elastomers are seeing a resurgence of interest in high-tech films and extrusion coatings that combine low-temperature flexibility, heat resistance, elasticity, permeability to water vapor, and chemical resistance.

From building construction to medical supplies to food packaging, copolyester thermoplastic elastomers are seeing a resurgence of interest in high-tech films and extrusion coatings that combine low-temperature flexibility, heat resistance, elasticity, permeability to water vapor, and chemical resistance. Although some of these niche applications have existed for as long as 15 years, new ones are now emerging and interest among both extrusion processors and end users is expanding after a period of relative quiescence.

Current U.S. output of copolyester film and extrusion coatings is in the range of 2 million to 2.5 million lb/yr, produced by 10 to 15 processors. Those numbers are slightly higher in Europe.

Copolyester TPE film and coating markets divide into breathable and non-breathable applications. Breathable is the largest and oldest sector, and its largest component is medical uses like surgical gowns, drapes, and dressings. Copolyester TPE films and coatings are permeable to moisture and gases (O2 and CO2) but are non-porous and thus impermeable to liquid water, blood, and bacteria. Other applications are diapers and adult incontinence products, in which these resins have the advantage of softness and quietness (they accommodate wearers’ movements without rustling). Another important market is in construction—semi-permeable roofing membranes and “house wrap” (breathable barriers). Breathability while repelling liquid water also accounts for uses in sporting goods, rainwear, and shoe liners.

Non-breathable applications take advantage of copolyester TPEs’ heat and chemical resistance, low-temperature flexibility, weatherability, puncture resistance, abrasion resistance, and low water absorption. Among these are the newest and fastest growing markets in wholesale food packaging, especially applications that require freezing products in the bag. Copolyester TPEs are also being considered for modified-atmosphere packaging (MAP). In monolayer films, these resins have a desirable non-stick tendency with many foodstuffs. In multilayer films, they have a high affinity for nylons, polyesters, EVA, and EMA copolymers.

Copolyester TPEs can be extruded easily into blown or cast films down to less than 1-mil thickness. With proper technique, cast films as thin as 0.2 mils can be achieved. Extrusion coatings on non-woven substrates are commonly produced as thin as 0.5 mil. Processors with experience in nylon extrusion have adopted copolyester TPEs without difficulty. Breathable applications, including coatings, typically utilize softer grades of less than 55 Shore D hardness, while harder grades appear in non-breathable uses of monolithic films.

Arnitel is DSM Engineering Plastics’ family of copolyester TPEs. They include both copolyether-esters and copolyester-esters. These resins are multi-block copolymers in which butylene terepthalate hard segments and poly (alkylene oxide) soft segments alternate repeatedly along the polymer backbone. Varying the type and amount of soft segment in any given copolyester formulation leads to a wide range of products and performance characteristics (see accompanying table).

Examples of typical grades include the following:

Arnitel PL380, a breathable, low-viscosity, 38 Shore D grade for extrusion coating.

Arnitel PM381, a breathable, medium-viscosity, cast-film grade of 38 D hardness.

Arnitel EM400, a less breathable, higher-strength film grade with 40 D hardness.

Rheological properties

In general, the crystalline melting point of copolyester TPEs increases and becomes more defined as the formulation increases in hardness (i.e., contains less soft segment). Melt viscosity is strongly dependent upon melt temperature and the hardness of the grade used. Softer grades have a higher melt viscosity at normal processing temperatures. As Shore hardness of the TPE increases, it takes on more crystalline character. Therefore, the melting point increases but is also more abrupt. As a result, average melt temperature is actually lower for harder than for softer grades. The most commonly used Arnitel film and coating grade is PM381, a soft material that can be extruded over a relatively broad range from 450 F to about 525 F.

As shown in the accompanying graph, copolyester TPE melt viscosity has a relatively flat response to shear rate. This means one cannot rely on high-shear screw and die designs to reduce the melt viscosity via shear thinning. Rather, the extrusion melt temperature can be increased or decreased to enhance the fluidity or melt strength of the extrudate. This implies that good control of melt temperature is required to reach and maintain a stable process with copolyester TPE resins.

Since these resins are based on polyester, absorbed moisture in the polymer during processing can affect the final properties. For this reason, Arnitel is supplied in moisture-proof bags with a maximum moisture specification of 0.05% (500 ppm) by weight. Once opened and exposed to moist air, the granules pick up moisture rapidly. Moisture levels above 0.10% may seriously impair an extrusion operation, causing highly variable melt pressure and extruder output, degradation of the resin, and possibly bubbles in the melt as it exits the die.

Copolyester TPEs are typically extruded with a drying hopper. For material that has been exposed to moist air, drying conditions are 3-4 hr at 212-248 F.

Extruder considerations

Extruders suitable for use with plasticized nylon, PVC, or polyolefins are usually suitable for extrusion of copolyester TPEs. A length-to-diameter (L/D) ratio of at least 24:1, and often 28:1, provides the required melt homogeneity for thin-film extrusion. The clearance between the screw flights and the barrel wall should be small to prevent backflow of molten resin and possible surging. A 24:1 L/D barrel should be equipped with a minimum of four independently controlled heating and cooling zones.

Grooved feed sections are not recommended. The grooves, which are designed to promote the forward motion of the pellets, can cause over-feeding of the compression zone of the screw, which results in poor temperature control, entrapped air, and high drive-power requirements.

In general, simple three-zone, general-purpose screws having feed, transition (compression), and metering zones of approximately equal length work well with copolyester TPEs. Compression ratios should be between 2.5:1 and 3.5:1, as determined by the depth of the feed-zone channel divided by the depth of the metering-zone channel. A screw flight pitch equal to one screw diameter is recommended.

Screw designs should not incorporate overly deep channels in either the feed or the metering sections. A deep, short feed channel can cause poor feeding and loss of output. A deep metering channel can result in a wide temperature distribution throughout the melt. Conversely, a shallow metering channel can result in overheating the melt due to high shear.

Screws having decompression zones and vacuum venting are not recommended for copolyester TPEs for several reasons. First, it is not possible to dry these resins by vacuum venting. Second, the vent and decompression areas may cause flow stagnation and localized build-up of degraded polymer. Third, irregular extruder pressure may result.

Some screws containing high-shear mixing elements and barrier-flight designs have been used successfully with copolyester TPEs. However, some of these designs can create high melt temperatures that cannot be controlled over a typical range of extruder throughputs. This is most evident in larger diameter extruders.

Both the extruder adapter and head should be as short and streamlined as possible. Flow channels should not contain sudden or dramatic changes in cross section or “dead spots” of any kind. Long adapter pipes can lead to polymer stagnation. This can lead to localized polymer degradation and subsequent random release of particles of degraded resin into the melt stream.

Cast film

To avoid sticking, chill-roll surface temperature should not exceed 122 F for soft Arnitel types (35D and 40D hardnesses), 176 F for 47D to 63D types, or 212 F for 72D and harder grades. Texturing of the chill roll will not only help film release but will also reduce the gloss level of the film.

The thinner the film and the more flexible the grade of TPE, the more critical tension control becomes during cast-film production. Without good tension control it is difficult to produce a uniformly wound, wrinkle-free film. Trimming or slitting of thin, flexible films also requires precise tension control. The best results have been obtained by isolating the slitting location from any vibrations or variations in tension that can be created by the wind-up or trim-removal systems. Driven rolls on both sides of the slitting location are recommended.

Blown film

Blown film is a relatively new use for copolyester TPEs. Only a few processors have done it commercially, and they have kept the details pretty much to themselves. By and large, however, they are using standard nylon film equipment. Blow-up ratios are a normal 2:1 to 2.5:1. Softer grades of TPE may need antiblock, as is also true in cast film extrusion.

Extrusion coating

Copolyester TPEs can be extrusion coated onto woven and non-woven fabrics. Chill-roll temperature can have an important effect on fabric adhesion. Typical temperatures are between 68 and 120 F. Unlike extrusion coating of polyolefins, a very small air gap between die and nip roll is recommended for copolyester TPEs.

Related Content

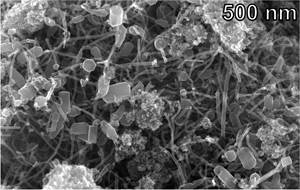

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More