In Food Packaging, Peelable IML Serves as Tamper-Evident Seal

Eliminate threaded closures and induction-sealed liners with ‘functional’ IML.

A novel concept proposed by two Canadian package designers is intended to save costs and container weight by replacing threaded flip-top closures and induction heat-sealed liners with a peelable in-mold label (IML) that acts as a tamper-evident seal. Stephen Robert and Bill Traynor, partners in KBS Impact Inc., Mississauga, Ont., have patented one version of this concept and have a patent pending on another. They call this approach “functional IML” or “FIML.” They believe it has wide potential in applications such as non-dairy creamers, nutritional-supplement drinks, ketchup, mustard, salad dressing, vitamins, OTC drugs, drink powders, bath crystals, bath soap, wide-mouth overcaps for yogurt and other spoonable foods, gable-top containers with threaded closures for liquid foods, and even personal-care products in squeeze tubes. KBS Impact is looking for development partners to help commercialize applications or license the technology.

SAVING COST AND WEIGHT

The patent-pending variant of this technology is dubbed UfLIPseal. To envision how it would work, imagine a squeeze-bottle condiment dispenser or a rigid bottle for vitamin tablets. To utilize either product, the consumer must, in some cases, remove a bottle neck wrap, then unscrew the threaded overcap, puncture or peel off the tamper-evident seal on the container neck—often a multi-layer foil composite applied by induction heat-sealing—and then replace the hinged flip-top closure.

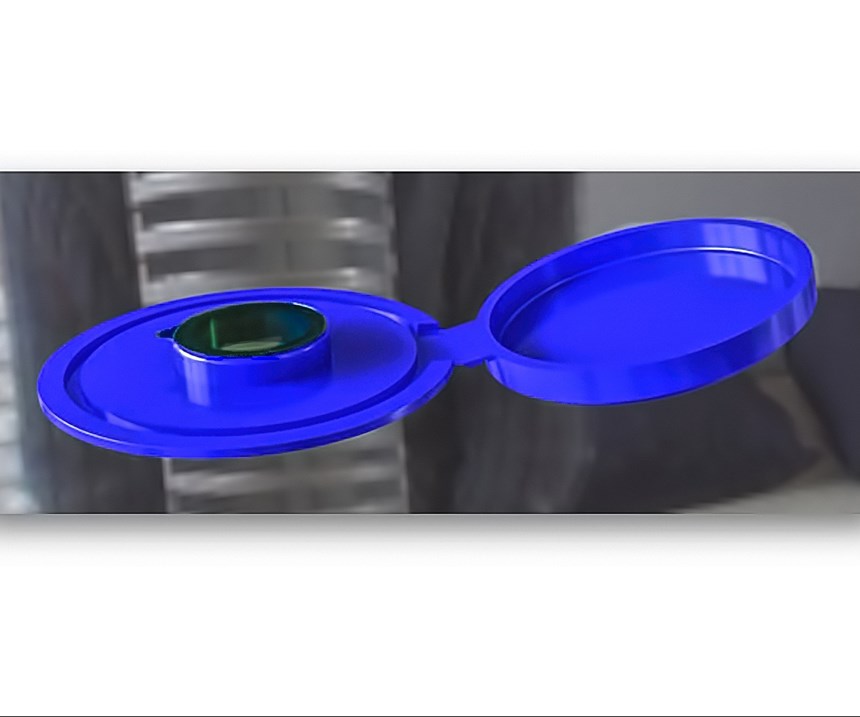

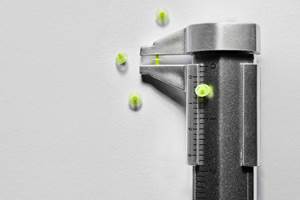

With UfLIPseal, the alternative is to injection mold the hinged closure with a peelable IML film, which can be decoratively printed or not, covering the cap’s opening. Both cap and IML film would typically be polypropylene. The low-profile, non-threaded closure has a horizontal flange that allows it to be ultrasonically welded to a mating flange on the container neck immediately after the container has been filled with product. After retail purchase, the consumer need only peel off the IML film, using a free-standing tab provided for that purpose. No need to take off the whole cap and replace it—in fact, the cap is permanently joined to the container.

Improved consumer

experience and

lower production

costs are offered by

‘functional IML.’

According to Stephen Robert, UfLIPseal offers several benefits to the producer, as well as the consumer. Eliminating threads in the overcap simplifies injection tooling and saves some cost. More important, it removes weight from both the cap and container neck, saving several grams of plastic—as well as molding cycle time, according to Robert. Another half-gram or so, and attendant costs, are saved by eliminating the neck overwrap and the induction-sealed foil composite. The lower profile of the nonthreaded UfLIPseal container neck and closure also reduce the overall height of the package, as shown in the accompanying photos. And eliminating threads adds design freedom, says Robert, since the cap and container neck need no longer be round.

Robert says ultrasonic welding of closures and containers is already proven in high-volume packaging of dairy products such as yogurt. What’s more, he says ultrasonic welding takes only 20% as much energy as heat sealing, and the ultrasonic welding heads are available instantaneously, as they require no heat-up time.

Robert acknowledges a couple of limitations in this approach. One is that ultrasonic welding requires the cap and container body to be of the same or similar materials. So the intuitive choice of materials would be PP to PP. Or a PET bottle would need a PET cap with a living hinge, which Robert says is technically possible. A second point is that food and drug packagers have large investments in filling lines, which would require substantial modification to convert to UfLIPseal technology. For that reason, Robert envisions it being used primarily in new products so that filling lines can be designed specifically for the new approach.

IML LID WITH A SPOON ATTACHED

KBS Impact’s currently patented variant of FIML is called U10Seal. It is aimed at single-serve yogurt, pudding, dry cereal, dry noodles, or other spoonable foods for wide-mouth tub-style containers. In this case, a preprinted IML label is placed in an injection mold and a ring of plastic is molded against the outer perimeter. This ring is later ultrasonically welded to a flange on the container body. The added feature of U10Seal is suggested by the name (a pun on “utensil”): a plastic spoon is molded onto the center of the IML film. Because the film is peelable, the spoon can be pulled off the film after peeling open the container.

Related Content

Slimmer All-Electric Press Debuts

NPE2024: A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreIn-Mold Labeling Applied to Medical

In collaboration with multiple partners, Arburg will showcase IML for centrifuge tubes at Fakuma 2023, eliminating printing or other downstream steps.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreKurz Opens New Plant in Vietnam

The maker of decorative thin films invested 37 million euros in the new 60,000-m2 plant in Quy Nhơn, which joins regional production facilities in China and Malaysia.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More