LM Industries Accelerating 3D-Printed Vehicles

LM Industries’ subsidiary Local Motors is reinventing traditional auto manufacturing as the original gold standard for 3D-printed vehicles.

Known for its 3D-printed solutions, Local Motors in Phoenix, Ariz., has been a leader in innovation, from the crowd-sourced Rally Fighter in 2009 to the world’s first 3D-printed car, the Strati. In 2018, Local Motors and a collaborative design community, Launch Forth, were restructured as LM Industries, based in San Francisco. LM Industries says that bringing Launch Forth’s design and Local Motors’ microfactories into one parent company provides a better alternative to mass manufacturing that gets the right products into the right people’s hands at the right time. With shared resources and capabilities, LM Industries will explore more ambitious and ground-breaking projects.

“Mass manufacturing is a relic of a past era. We’re in the middle of a mobility revolt where current modes of transportation are not sustainable and do not match up with rapidly changing consumer preferences,” says LM Industries CEO and co-founder John B. Rogers Jr. “We can’t keep producing products the same way we’re accustomed to. The world is moving too fast for traditional manufacturing to keep up. LM Industries is on a mission to transform mass manufacturing to micro-manufacturing in order to match the new pace of technology and quick-changing consumer needs.”

LM Industries calls itself the world’s first digital OEM, which can take concepts to deployed products in under one year, all on its unique digital thread. It brings products to market in an entirely new way, designing with its global community of experts, and applying technology such as 3D printing to create and assemble products in small batches at agile microfactories.

LM Industries creates transportation, accessibility and mobility products with customers such as Allianz Group, Airbus and the United States Marine Corps. Its efficiency allows products to be upgradeable like software--iterated regularly and fluidly to match rapidly changing consumer preferences.

One concept that continues to gain momentum is the company’s small autonomous shuttle vehicle named Olli.

3D-PRINTED, SELF-DRIVING VEHICLE

Created in 2016 by Local Motors, Olli is a 3D-printed, self-driving “smart shuttle,” built to change the future of mobility. Olli employs a responsive cognitive function and a Robotic Research-developed autonomous drive system. It’s a viable and sustainable transportation option for cities, hospitals, campuses, entertainment districts and any other location where people need to move from one place to another.

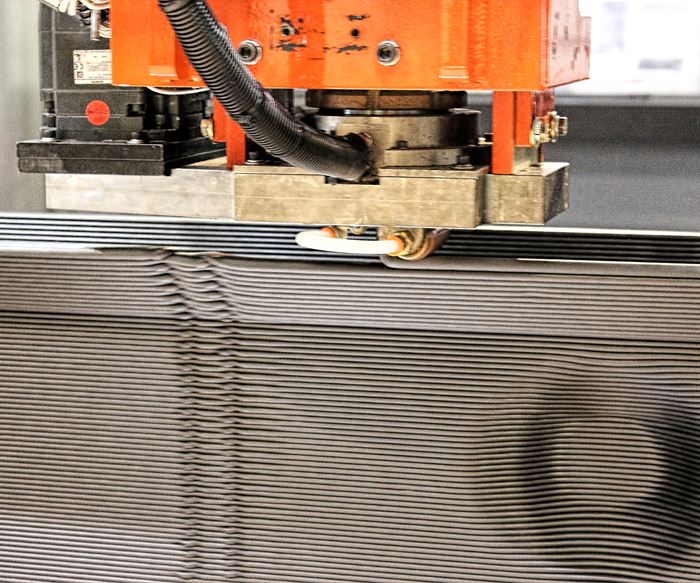

LM Industries sees carbon fiber as a core component of the future of additive manufacturing and it’s essential to the Olli, which is built from carbon fiber-reinforced thermoplastics.

Thermwood, Dale, Ind., installed the Large Scale Additive Manufacturing (LSAM) system at Local Motors’ facility in Knoxville, Tenn., to produce Olli. With a build envelope of 10 x 40 ft, It’s said to be the world’s largest composite 3D printer. LSAM is designed for additive manufacturing of large structures using a fundamentally different approach, according to Thermwood. The system at Local Motors is 40 ft long but Thermwood says these machines can be up to 100 ft long. LSAM provides both print and trim on the same machine and can print both horizontally and vertically.

Local Motors has used large-scale additive manufacturing for some time now, in 2014, the company invested in BAAM (Big Area Additive Manufacturing) 3D printers by Cincinnati Inc.

“The market has grown and we’ve been part of the market growth and have more large-scale 3D printers than anyone else in the world,” says Greg Haye, v.p. of product management at Local Motors. “The new generation of machinery is able to print at a higher throughput; we now have the ability to print the larger structures like Olli, which also allows flexibility to explore other areas.”

Since Olli is custom designed and 3D printed, different features can be added so that a new shuttle can be designed and printed to fit a city and campuses. Local Motors can simply change the file and a print a batch of Ollis that fit a customer’s needs. The company believes that this is “revolutionary.”

In early August, Olli was deployed at the State University of New York at Buffalo as part of a partnership with the school and New York State. The shuttle is being used on campus for mapping, autonomous education and testing potential transportation options.

This past summer, Jay Rogers, CEO and co-founder of Local Motors, announced the first-of-its-kind Fleet Challenge to invite municipalities, campuses and designated districts to propose a short-term, local use for Olli. Winning entries for the first challenge came from Phoenix, Ariz., and Sacramento, Calif.

EVIT, Arizona's first joint technical education district, earned the bid for the Phoenix-area Olli deployment, after being evaluated among several entrants for the competitive opportunity. Sacramento State, California's capital university, earned the bid for the Sacramento-area Olli deployment. Local Motors officials expect to deploy fleets for public use starting in 2019.

Local Motors will open a second fleet challenge for Olli, offering the opportunity to entries in the Greater Washington, D.C.-area, which will run until early February. One location will be selected to receive a fleet of eight-person Olli shuttles to use for about three months. Additional fleet challenges, with unique judging panels, will continue to roll out in the coming months.

“There’s more production ready machinery and processes in place; it’s really matured in the last few years,” Haye says. “Software, equipment and materials are all growing together so that we have better slicing, machinery, better g-code and a more efficient lightweight structure.”

Related Content

PEEK for Monolayer E-Motor Magnet Wire Insulation

Solvay’s KetaSpire KT-857 PEEK extrusion compound eliminates adhesion and sustainability constraints of conventional PEEK or enamel insulation processes.

Read MoreInjection Molded Enclosures Plug into Potential Electric Vehicle Battery Applications

In partnership with material suppliers, Engel is proving out injection molded thermoplastic-based concepts for electric vehicle battery housings, utilizing production tools and dedicated machines at its large press factory in St. Valentin, Austria.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreNew CRM Streamlines Quoting for Automotive Molder

Eliminating the need to contact each supplier for every individual quote, a new CRM for automotive supplier Axiom Group tracks past quotes as well as industry history to generate fast, reliable RFQs and more.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More