Low-Pressure Injection Molding Technology Boasts Faster Cycles, Better Parts

Available for license, this low-pressure process “breaks the rules” of injection molding, but has numerous benefits for molders.

Low-pressure injection molding technology developed at Procter & Gamble and now being offered for license is said to offer advantages in molding productivity, part quality, and design freedom. iMFLUX Inc., Hamilton, Ohio, is a new subsidiary of P&G created in 2013 to market the technology. It was born of a challenge issued by former P&G CEO A.G. Lafley, who asked why a company like Toyota could design and build a whole new car model so much faster than P&G could change the cap on Pantene shampoo. From that emerged a goal to build injection molds for P&G products in half the time and cost of conventional methods. P&G engineers identified the high pressures of injection molding as a major cost and time driver in building molds and pursued ways of overcoming this hurdle.

The public debut of iMFLUX was at an October open house hosted by KraussMaffei Corp., in Florence, Ky. In a technical presentation there, Gene Altonen, chief technical officer for iMFLUX, said this low-pressure technology offers economic advantages: 10-25% or more faster cycles, 25-50% or greater reduction in melt pressure, up to 50% lower clamp tonnage, and ability to mold thinner walls without freeze-off and to increase mold cavitation. Altonen showed how two parts 0.045-in. and 0.025-in. thick could be molded at the same pressure,

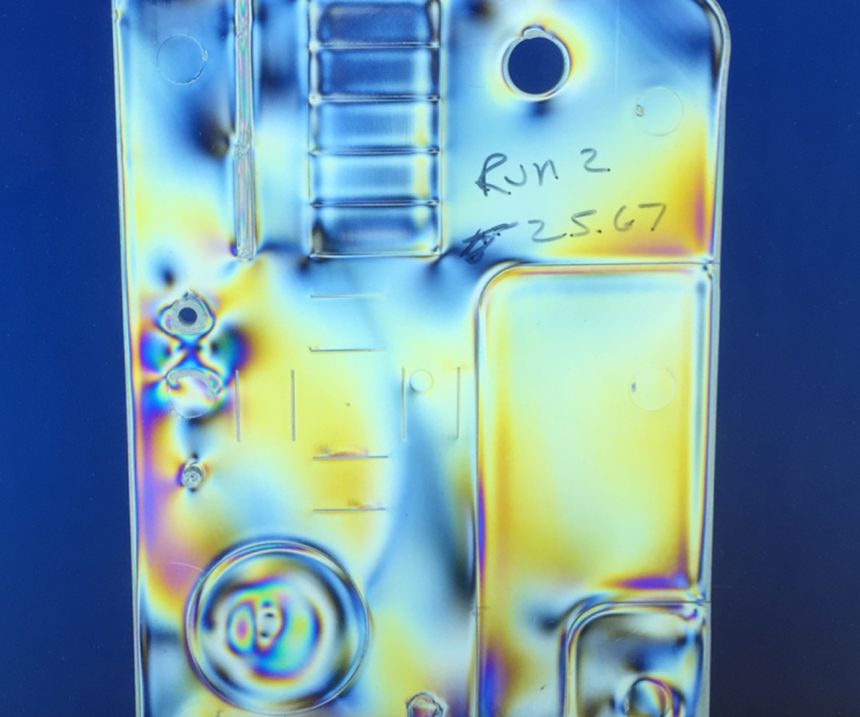

saving energy. Quality advantages with iMFLUX, he said, include reduced molded-in stresses, more uniform filling of multicavity molds, and elimination of flow-front hesitation for improved part aesthetics.

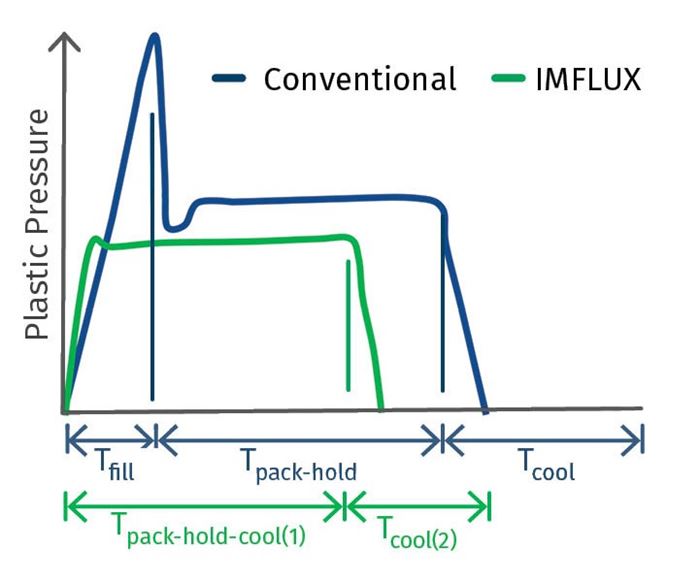

The iMFLUX process breaks many of the rules of conventional injection molding. The key is filling at a constant, lower pressure, without the usual reliance on shear thinning to facilitate flow. Slower filling without hesitation yields faster cycles. This also allows for a cooler melt that can flow farther through thinner channels. Whereas conventional injection molding separates mold filling, packing, and cooling into sequential steps, iMFLUX combines them all simultaneously. “If you stop a short shot, you’ll see that it’s fully packed, with a fully formed surface at every point during fill,” Altonen said.

The firm’s proprietary software and controls utilize a pressure sensor in the machine nozzle as the primary control point to ensure consistent filling without flow hesitation, based on sensing melt pressure every 1.2 millisec. Altonen showed a 3-in.-long runner only 0.030-in. thick: “Any hesitation would cause it to freeze off.” A single cavity-pressure sensor—regardless of how many cavities there are in the mold—is also used to detect end of fill. This approach is said to adjust immediately and automatically to any change in resin viscosity—caused, for example, by changes in regrind quality or percentage, or by a color change. Altonen said the cost of installing a cavity sensor could be saved by means of an iMFLUX invention called Nighthawk, which is installed on the outside of the mold to detect strain and deflection as a proxy for measuring melt pressure inside the mold. Nighthawk gives readings all during fill, not just at the end like a cavity sensor.

Altonen cited the case of a 16-cavity mold that experienced intermittent short shots. Adding pressure sensors to each cavity showed a 3439-psi range of pressures at end of fill. With iMFLUX, that range shrank to 1113 psi without modifying the mold or hot runner. Other examples of what iMFLUX has achieved include one customer that was able to shift a mold from a 700-ton to a 400-ton press. Another reduced cold-runner volume by more than 50% while trimming cycle time. Still another trimmed resin use by more than 25% with thinner walls than were possible with conventional technology.

iMFLUX can be installed on any existing mold and machine. iMFLUX also designs and builds molds to take advantage of its process technology.

Altonen will discuss iMFLUX technology at Plastics Technology’s Molding 2018 Conference, Feb. 27-Mar. 1 in Long Beach, Calif. Get information on the program and registration here.

Related Content

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More