Making IML Even More Cost-Competitive

Absolute Robot Inc. shows economical IML automation system for the first time.

“When we started Absolute Robot Inc. in 2013, our goal was to help keep North American molders competitive by supplying high-quality, cost-effective automation. We wanted to help bring business back to the U.S.—‘onshoring,’ as it’s called. If you can make a product at a competitive price, wouldn’t you rather make it here?”

That, in short, was the founding philosophy behind ARI, as explained by Tim Lavigne, business manager. At this year’s NPE, his firm will be showing an example of the servo-driven Cartesian robots made by Well-Lih in China—in this case, a five-axis model BW10-1500A+C—that ARI has been offering at prices 10 to 20 percent below others on the market.

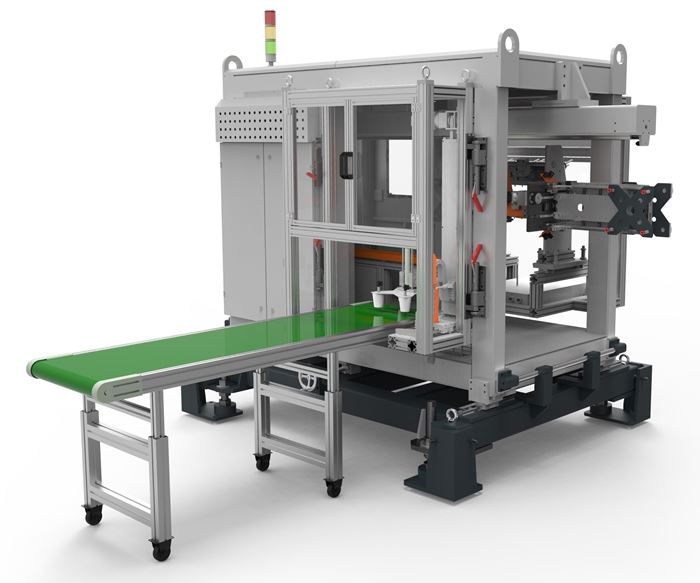

But ARI also has chosen this show to kick it up a notch. The highlight of its booth (W4182) is an in-mold labeling (IML) system from Well-Lih that is said to perform in the same league as industry-leading competitors but costs 20 to 30 percent less. “American molders have been asking us about IML for the last five years,” says Lavigne. “We’ve had enough experience now that we decided the time was right to take this step.”

ARI is offering both side-entry and top-entry IML systems suitable for overall cycle times down to 3 sec, which is competitive with today’s benchmarks. “We can handle high-speed IML systems for food packaging,” says Lavigne. “We have quoted systems for 1.8-sec mold-open times. And we can also tackle larger products like 5-gal buckets, kitty-litter pails, or candy bowls. Our sweet spot is IML systems for 100- to 300-ton presses, which generally will use side-entry automation. For larger machines—400- to 500-tons—molders will need top-entry systems.”

To prove its point, ARI will operate a Zhafir Venus II all-electric injection machine (259 tons) sold by sister company Absolute Haitian together with a side-entry IML system and a four-cavity PP yogurt-cup mold. “It shows we can offer complete turnkey systems,” says Lavigne, “with robot, end-of-arm tooling, label magazine, height-adjustable frame, and options like vision and stacking parts either bottom-up or bottom-down.”

Related Content

-

ABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.