Materials Close-Up

To succeed in Detroit, it’s not enough for polypropylene-based TPO elastomers to be low-cost, lightweight, easily processable, and recyclable. They also have to look good for the life of the vehicle.

In TPOs, Good Looks Are Not Just Skin Deep

To succeed in Detroit, it’s not enough for polypropylene-based TPO elastomers to be low-cost, lightweight, easily processable, and recyclable. They also have to look good for the life of the vehicle. TPO makers have responded with steady improvements in paint adhesion and in full-depth molded-in color that eliminates the cost of painting. The latest advances in these directions were major themes of the recent SPE Automotive TPO Global Conference 2000 in Dearborn, Mich. The conference also unveiled new additives that enhance TPO stiffness or that improve performance of flexible TPOs for interior skins.

Color all the way through

Solvay Engineered Polymers, Auburn Hills, Mich., presented its latest success in overcoming the special challenges of using metallic pigments in unpainted exterior parts. The 1999 Jeep Grand Cherokee Laredo was the first vehicle to use metallic molded-in-color fascias and body side claddings, based on Solvay’s Sequel TPOs. This year, Solvay’s focus was on DaimlerChrysler’s 2001 PT Cruiser, which uses metallic-pigmented TPO in a partially painted, two-tone fascia. This large, one-piece bumper is molded of Sequel 1440. The fascia, which is pigmented a light silver/quartz color, is unpainted in the center while the lower grille is painted a dark metallic gray. The TPO substrate incorporates a proprietary uv stabilizer system that ensures the unpainted portion will maintain its appearance for the required 10-year lifetime. Unlike typical uv stabilizers, this system also reportedly does not interfere with painting.

The precolored metallic substrate provides color consistency throughout the thickness of the part, so that scratches and chips are less noticeable. Solvay found that aluminum flakes of 26-90 microns with a highly reflective silver color provide a random sparkle effect that is maintained in extrusion and injection molding processes. Flake loadings of 0.6-1.2% had very little effect on the TPO’s shrinkage, impact strength, or paintability.

Basell North America Inc. (the new name for Montell North America) in Wilmington, Del., reported on its development of special PP-based polymers for making exterior body panels with molded-in color, including metallic colors. Basell is pursuing the concept of melt-phase thermoforming body panels from two-layer coextruded sheet as an alternative to both engineering thermoplastics and fiberglass-reinforced thermosets. Basell has developed multi-layered structures with flexural moduli from 18,000 to 500,000 psi, ductile/brittle transition temperatures lower than –20 C, and 60° gloss values above 80%. Body panels with excellent part definition and draw ratios of 300% to 400% have been formed. Basell also reports that its technology utilizes all of the in-process scrap.

The first commercial use of one of these thermoformed coex structures with molded-in color will be a bumper fascia for a pick-up truck. It will be thermoformed by Prodesign of Elkhart, Ind. (Basell sources did not name the auto maker.) Also in development is an engine cover for an ATV (all-terrain vehicle). In both cases, the 240-mil sheet has a cap layer (20% of total sheet thickness) of developmental Resin X-9570-71-1, a specialty high-gloss PP with a flex modulus of 200,000 psi and Rockwell R Hardness of 75. The developmental substrate, designated X-11598-13-6, is an unusual, non-rubber-modified TPO. Basell confirms that the substrate contains some of the company’s new high-melt-strength (HMS) PP, which was developed specially for melt-phase forming of heavy-gauge sheet. Overall properties of the sheet include 60° gloss of 89%, flex modulus of 217,000 psi, and Rockwell R hardness of 95.

Making paint stick better

Two other presentations focused on new materials designed for enhanced paint adhesion. Equistar Chemicals of Houston provided details on a new high-stiffness TPO with improved durability and paint adhesion for thin-wall bumper fascias. Launched this past summer, Flexathene TP4346-HS is based on a reactor TPO that achieves an improved stiffness/impact balance by raising the crystallinity of the homopolymer PP phase while tailoring the rubber phase to maintain low-temperature ductility.

TP4346-HS reportedly maintains ductility at –30 C, even with the addition of a carbon-black concentrate, which typically leads to a decrease in impact strength. Paintability was also shown to be excellent, with 0% paint loss in the GM9071P tape-pull test. Initial paint adhesion, heat and moisture resistance, and moisture and cold-cycle resistance were all rated excellent. Taber abrasion tests showed 0% loss at both the gate area and elsewhere on the part.

This 17 MFR, 0.92 g/cc TPO has a flex modulus of 150,000 psi, notched Izod impact of 12 ft-lb/in. at 23 C and 1.0 ft-lb/in.at –18 C, and Gardner impact of 340 in.-lb at –18 C.

Basell reported on developmental directly paintable TPOs with flex modulus ranges from 94,250 to 159,500 psi. They need no external treatment of the TPO surface to render it more polar nor a tie layer between the TPO and the paint. Basell is using additives of various levels of polarity and molecular weight to provide a directly paintable resin surface that will provide long-term adhesion to polar paints. The approximately 20% higher cost anticipated for the directly paintable formulations is said to be more than compensated by the overall cost reduction in the painting process.

Metallocene reactor TPO

Aesthetics were not the only focus of the SPE meeting. According to ExxonMobil Chemical Co. in Houston, new reactor-made TPOs that incorporate metallocene technology have a stiffness/impact balance previously available only with traditional compounded TPOs. New Exxpol Enhance PP8224 TPO for exterior parts has a 25 MFR, flex modulus of 160,000 psi, notched Izod impact of 9.9 ft-lb/in., and instrumented impact of 22.9 ft-lb (ductile) at 23 C and 31 ft-lb (ductile) at –30 C.

This TPO is said to meet the stiffness and low-temperature ductility requirements for medium-wall-thickness (2.8-mm) fascias without help from mineral fillers. ExxonMobil reports that unfilled PP8224 at 0.90 g/cc saves 1 to 2 lb, or 10%, versus a typical filled TPO at 1.00 g/cc. Also, the stiffness of the new unfilled reactor TPO could reduce the wall thickness for a typical midsize vehicle fascia from 3.2 mm to 2.8 mm, a 12.5% reduction. In molding tests of a 10-lb fascia, fill time was 5 to 7 sec with a PP8224-type resin vs. 7 to 14 sec for a filled TPO. Cooling time was 20 sec for the reactor TPO versus 25 to 35 sec for conventional filled TPO. Also, easier flow of the new TPO reduced flash, knit lines, “tiger stripes,” and stress whitening.

For molded-in color applications like bumper step pads, PP8224 can be pigmented at the molding machine using a uv-stabilized color concentrate with a carrier tailored to the viscosity of the resin. Step pads made with the new TPO achieved a Delta E reading of 0.154 after xenon-arc accelerated weathering exposure to 5000 kJ/m2, double the usual standard. The pads also easily passed one-year outdoor weathering tests in Florida. Ongoing paint-adhesion and durability testing indicates good to excellent performance, the company reports.

Additives hike properties

Citing auto makers’ increased interest in flexible TPOs for interior skins, DuPont Dow Elastomers, Wilmington, Del., unveiled experimental, higher viscosity ethylene-octene elastomer modifiers for TPO sheeting. These new polyolefin elastomers (POEs) resulted from recent advances in the company’s Insite metallocene catalyst technology. They have been produced on a pilot scale with various molecular-weight distributions and Mooney viscosities up to 45. When tested with two different automotive interior-skin technologies, these POEs exhibited rheological characteristics similar to EPDM of 45 Mooney viscosity. However, the POEs had better physical properties than EPDM, such as 75% to 85% higher tensile strength, 100% higher elongation, and 35% to 45% higher tear strength. TPOs containing these higher-molecular-weight POEs also showed better thermoforming characteristics.

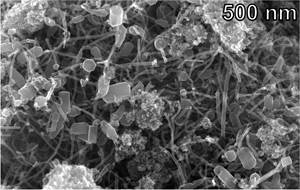

Compounders seeking higher stiffness in TPOs have a new option in R Talc from Luzenac America, Engelwood, Colo. This developmental, surface-modified, high-brightness talc of 1.8- to 3-micron particle size is said to yield TPOs with 16% to 55% higher flex modulus than is provided by unmodified talc, even with higher-flow TPO grades. So far, this effect has been observed in TPOs modified with EPDM or EPR but not with metallocene POEs. Work is under way to eliminate that difference in performance.

New ultra-high-molecular-weight siloxane masterbatches can serve as processing aids and surface enhancers for TPOs, according to Dow Corning Corp., Midland, Mich. Masterbatches MB50-321 and MB50-011 contain 50% UHMW siloxane in PP homopolymer and nylon 6 carriers, respectively. Addition of 2% to 6% masterbatch is said to considerably increase the scratch resistance of talc-filled TPOs, although MB50-011 gave better performance with both the Ford Five Finger tester and Hot Taber instrument. Dow Corning sources hypothesize that scratch resistance results from synergistic effects of the nylon 6 hardening the surface of the TPO while the UHMW siloxane reduces the coefficient of friction.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More