Metal-Powder Injection Molding Moves Into Larger Parts

It’s not just for small parts anymore: One of the latest developments in metal-powder injection molding (MIM) is its first commercial large part—a 3.5-lb flow-body housing for a passenger jet plane.

It’s not just for small parts anymore: One of the latest developments in metal-powder injection molding (MIM) is its first commercial large part—a 3.5-lb flow-body housing for a passenger jet plane. The flow body directs hot air from the jet engine to other parts of the plane, such the passenger cabin for heating. Now in the final stages of qualification, the part was developed by the molder, Polymer Technologies Inc. (PTI), Clifton, N.J., in cooperation with Honeywell Engines & Systems of Tempe, Ariz. According to Jerry C. LaSalle, PTI’s director of MIM operations, this is the largest and one of the most complex MIM parts in the world. It has a 3.3-in. inner diameter with thick and thin wall sections. PTI uses a nickel-based superalloy. “By forming the body by MIM to the required final part thickness, significantly less machining is required,” LaSalle says. “The metal alloy was selected for its strength, durability, and oxidation resistance at elevated temperatures—the very same capabilities that make it hard to machine with conventional methods,” he notes.

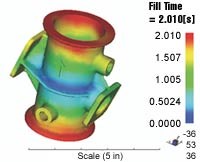

PTI used Moldflow’s MPI simulation software to reduce development time by several weeks and to obtain a high degree of process repeatability. PTI is reportedly one of the first molders to use flow simulation for MIM. “MPI simulation was critical for assisting with gate design and prediction of knit lines,” LaSalle says.

Raising the bar

MIM uses fine metal powders of 10 to 20 microns together with small amounts of plastic or wax binder. This highly viscous mix is injected into a mold. The resulting “green” or intermediate part is traditionally placed into a bath or oven to remove the binder. After this debinding step, the “brown” intermediate part is placed in a sintering oven to fully densify the part.

PTI, a plastics and metal parts molder, is a leading developer of the MIM process. It recently obtained a $4.05-million grant for MIM R&D from the National Institute of Standards and Technology (NIST) in Washington, D.C., under its Advanced Technology Program (ATP). PTI has five injection molding presses suitable for MIM. Although MIM constitutes less than 2% of the metal-forming business in the U.S., its growth potential encourages PTI president and founder Mel Goldenberg. “MIM is already gaining on our plastics operations in terms of total output,” he says.

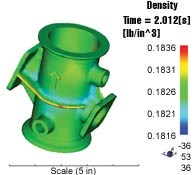

LaSalle notes that MIM has been used mainly for small parts in the range of 1 to 50 g. A vast majority weigh 10 to 15g. Gun triggers, watch bezels, and orthodontic components are some typical applications. Al though MIM has been around since the 1980s, persistent challenges such as knit lines, short shots, inconsistent part density, warpage, and shrinkage have raised scrap rates and lowered cost-competitiveness. “The defect rate on larger, more complex parts like aerospace, industrial, and automotive components has been far too high,” says Goldenberg.

PTI’s two-year ATP grant will help erase those obstacles. “A rule of thumb for MIM had been that a 1/8-in. part is difficult to debind, and a 1/4-in. part is impractical, but we are helping to raise that bar,” says Goldenberg.

The NIST-funded MIM research is actually a three-year program, but the original project leader, Honeywell, pulled out after the first year. PTI then became the team leader, working with six other companies and one university, all with expertise in different facets of MIM. One of these is Penn State University’s Powder Metallurgy (P/M) Lab, long a recognized leader in MIM development. Also part of the team is Latitude Manufacturing Technologies, provider of the novel seaweed binder technology used in the program.

The other members include H.C. Starck, Rutherford, N.J., a manufacturer of refractory metals; New Hampshire Industries, Lebanon, N.H., a metal parts supplier; CM Furnaces, Bloomfield, N.J.; and G5 Technologies, Cherry Hill, N.J., a producer of web-based management systems.

No debinding step needed

PTI is looking to develop a greater choice of metal powders and types of binder systems for MIM. Particularly exciting is its work with Latitude Manufacturing Technologies’ agar binder (originally developed by AlliedSignal and Honeywell). This binder is based on water and a gelatin-like material derived from seaweed. There is no need to remove this binder before sintering the green parts, thereby eliminating a formidable technical obstacle. Removing the binder from large, thick-sectioned parts had been one of the biggest hurdles to producing larger MIM parts. All that’s needed with agar binder is a few hours of air drying to evaporate the water that makes up most of the binder’s volume.

As we reported recently (see PT, Dec. ’02, p. 26), RTP Co. has begun offering pelletized versions of MIM compounds made by Latitude from metal powders with agar binder.

Computer simulation

The research group uses computerized molding and sintering simulation to predict and refine process parameters for high yield manufacturing. Sensors placed inside molds and the sintering furnace help analyze the internal state of the part as it passes through the various production stages. A web-based information system will be set up to disseminate the project’s results.

Understanding the effect of injection speed and pressures is essential to repeatable MIM molding. “Material flow divergence and convergence issues are very important when molding with metal,” says Goldenberg. PTI is using MPI software along with a library of material property data from Honeywell to create accurate flow simulations of the metal and binder. The simulation will help to determine the temperature windows for processing different metals and binders.

Goldenberg says one reason for using Moldflow’s software is its MPI/3D solution technique. “One must use true 3D simulation and not 2D or 2.5D because gravity, inertia, and laminar flow play a role when forming the part. Molders need to know the behavior of the material away from the wall,” says Goldenberg. MPI/3D is unique in using solid tetrahedral mesh elements to model thick parts like those made with MIM, which are not as accurately modeled with conventional midplane flow simulation.

Sintering is another area of focus for the program. The project is developing simulation software to predict material shrinkage and warpage and to optimize oven conditions for obtaining the highest-quality sintered parts.

ATP project partners CompAS Controls, a maker of furnace controls, and the Penn State P/M Lab are further developing sintering simulation software initially created at Penn State. The sintering simulation uses real-time furnace data (gas flow rate and temperature) to compute the state of densification throughout various stages in the furnace. The sintering simulation and real-time feedback allow PTI to operate the furnace under conditions designed for maximum product yield and accuracy.

Related Content

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More