New Report Details Aging of Manufacturing Workforce

Study from Manufacturing Institute also reveals best practices by companies that are meeting the challenge head on.

I had a wide variety of topics from which to choose as I sat down to write this column: the “greening” of K 2019 (coverage beginning on p. 36); the new boss at the Plastics Industry Association (PLASTICS), on p. 8; the decision of Coke and Pepsi to withdraw their membership from PLASTICS; the upcoming Manufacturing Day; and a few other things. Since some of those items are covered elsewhere is this issue, I decided to tackle another critical and timely subject: Workforce Development.

A piece of research hit my email box recently from the National Association of Manufacturers. Titled Aging of the Manufacturing Workforce: Challenges and Best Practices, the study concluded that attracting and retaining a quality workforce is one of the top challenges facing the manufacturing industry. As of 2017, the survey noted, nearly one-quarter of the manufacturing workforce is age 55 or older. Kind of scary. The Institute’s Center for Manufacturing Research collaborated with Keybridge Research for this study, which was funded by a grant from the Alfred P. Sloan Foundation.

The good news is that manufacturers have responded to the challenge in a variety of ways, including boosting recruitment efforts, adopting new technologies and taking steps to retain and maximize the productivity of their older workers (see p. 16 for an article on how one injection molder is dealing with the problem).

Key findings of the report include:

• Most manufacturing firms are both aware of and concerned about the aging of the manufacturing workforce. Almost all (97%) survey respondents report being aware of the issue, and the vast majority (78%) indicate that they are very concerned or somewhat concerned about this change.

• Manufacturing firms are particularly concerned about brain drain (loss of institutional and technical knowledge): 97% of firms express at least some concern about brain drain and almost half of firms indicate that they are “very concerned” about the issue. Survey results also show that many firms are concerned about a shortage of labor, declining productivity, and rising costs.

• Firms across the manufacturing sector are taking steps to mitigate the impact of the aging workforce on their business. Almost 90% of companies surveyed reported capitalizing on the talents and experiences of their older workers, and of these, 46% report benefiting from older workers “to a great extent.”

• Results from the survey and information collected during interviews with manufacturing firms show that those who have successfully dealt with the aging of their workforce target four main objectives, each of which can be achieved through a suite of underlying best practices.

Those four main objectives are:

1. Early Awareness

• Create open communication channels.

• Bring up retirement with employees as retirement age nears.

• Ensure that employees feel valued and secure.

2. Knowledge Transfer

• Establish and strengthen mentorship and apprenticeship programs.

• Collect and archive older workers' knowledge using centralized electronic records.

• Hire older workers with needed knowledge.

3. Retention and Productivity Maximization

• Make ergonomic adjustments and use robotics.

• Allow workers to transfer to another position internally.

• Adapt to workers' needs with flexible hours or phased retirement.

• Encourage workers to return part-time or through project contracting.

4. Boost Recruitment

• Incorporate older workers into recruitment efforts.

• Use referrals from older workers.

You can go themanufacturinginstitute.org and download the entire report. Click on Research on the top navigation bar, then select The Aging of the Manufacturing Workforce from the dropdown menu.

Related Content

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreSirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

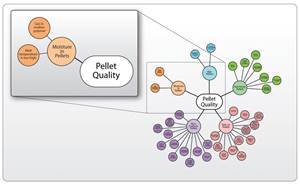

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More