New Technology Enables ‘Smart Drying’ Based on Resin Moisture

Sponsored ContentThe ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

Share

Novatec is moving to redefine resin drying with new, economically priced technology that detects moisture levels in the material before it hits the dryer and then adjusts the drying parameters accordingly. Called the DryerGenie, Novatec debuted the system at the 2023 Plastics Technology Expo.

The DryerGenie consists of two sensors: one that’s installed near the bottom of the suction probe or lance, which is typically used by molders to pull resin from gaylords to the dryer to prepare the material for processing; the second is mounted to the lance handle to measure ambient conditions. Both rely on capacitance or near-infrared technology to measure moisture in the resin on a parts/million (ppm) basis long before it’s drawn into the dryer.

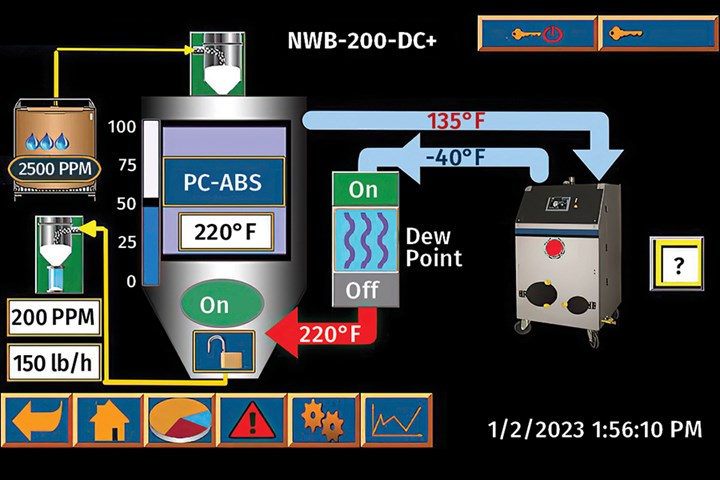

DryerGenie sensor (lower left) communicates real-time moisture levels and triggers changes to dryer setpoints. Photos/Charts: Novatec

The sensor constantly communicates with the dryer controller and automatically adjusts drying residence time, airflow and temperature to account for the moisture reading. The system is retrofittable to Novatec dryers purchased since 2016. At its laboratory in Baltimore, Novatec has run the DryerGenie on various nylons, PC, PC/ABC, acrylic and TPUs.

As Novatec explains, the patent-pending sensor apparatus also includes accelerometers, pressure sensors, temperature/humidity sensors and a gyroscope to assist in reliable inline moisture measurements. Since moisture presents a very high dielectric constant compared with the low dielectric constant of plastics, the presence of moisture can very reliably be detected, and then instructions are coordinated with the connected dryer to change drying parameters and residence time according to the moisture levels — by the time the material reaches the drying hopper.

“We’re changing the paradigm of resin drying and at the same time challenging some long-held beliefs,” notes Novatec CEO Conrad Bessemer. “The first is drying to the resin supplier’s recommendations that appear on the data sheet. These recommendations are usually very wide: 2-4 hr or 4-6 hr. That’s because by the time the resin reaches the processor, the moisture levels in it may have changed dramatically from when it was shipped and is highly dependent on seasonality.”

“Most processors think drying performance is all about dewpoint. That’s a fallacy.”

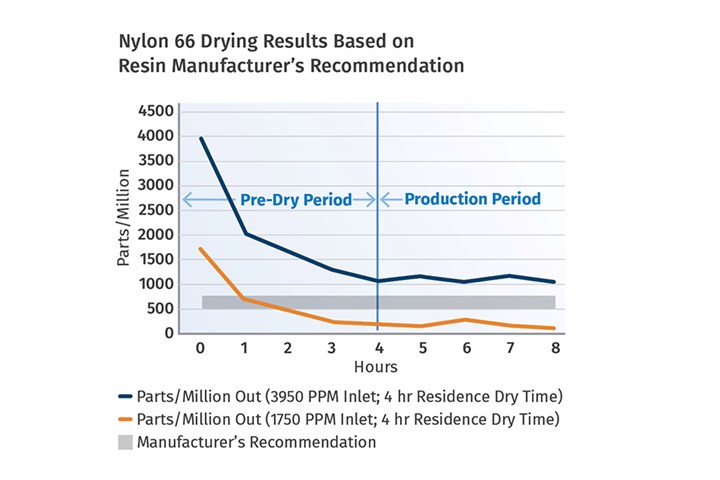

Mark Haynie, Novatec’s drying product manager, concurs: “Most drying times from resin data sheets include significant safety factors, which result in overdrying, wasted time and wasted power. In most cases, the starting moisture point is unknown. Even two gaylords received the same day can have dramatically different starting moisture points. To that point, we recently received two gaylords of nylon 66 from the same supplier on the same day. One came in at nearly 3950 ppm, the other at 1750 ppm. But the supplier’s recommendation for drying time and temperature were the same.”

The DryerGenie also takes aim at conventional wisdom about drying to dewpoint levels. Explains Haynie, “Most processors think drying performance is all about dewpoint. That’s a fallacy. Dewpoint is a measurement of the moisture in the air, not pellet moisture. Low-dewpoint air is useful in drying plastics but has nothing to do with the inherent moisture in the pellet. Dewpoint measurements indicate the dryer’s performance, not pellet moisture result. PPM or moisture percentage in the pellet is the only real way to measure dryness of the resin.”

He adds, “With the use of the Genie wand in your material input source, the dryer will know the moisture content of your resin immediately prior to processing and detect the changes in moisture over time. The Genie will use this information to automatically adjust the dryer control to achieve the most efficiently, properly dried material possible.” Adds Bessemer, “Drying should not be independent of moisture control. You don’t want to dry more than you need to. You don’t want to dry less, either. The DryerGenie is a marriage of moisture measurement and resin drying that will eliminate the guesswork.”

“If you know the moisture is already low in the resin, you can start making parts sooner.”

Able to run unattended, the DryerGenie sensor takes a sample of up to a pound of material at a time. According to Bessemer, other types of online capacitance-based sensors only measure perhaps 1/8 in. from the wall, whereas offline devices often only measure a few grams from a vial.

With DryerGenie, residence time can be increased if there is room in the hopper; if not, production needs to be slowed. Key is knowing inlet moisture level so you can adjust before making bad parts.

That Pesky Process

Drying tends to be vexing for even the savviest of processors. As Bessemer and Haynie point out, molders dry because they worry about making bad parts. Overdried parts tend to be brittle, making them prone to breakage; while underdried parts can cause splay and an assortment of other problems. The ultimate result is that many molders tend to cling to time-honored drying tradition of following the resin suppliers “cookbook.” But Haynie says that with the DryerGenie, molders now will “know the starting point of pellet moisture from the input source and, for the first time, be able to connect the moisture reading from the resin source with the precision dryer control and adjust drying time and parameters — and residence time.

“Also for the first time, the technology allows taking the moisture reading of the ambient room conditions to reliably predict the effect of ambient air on moisture gain for incoming pellets.”

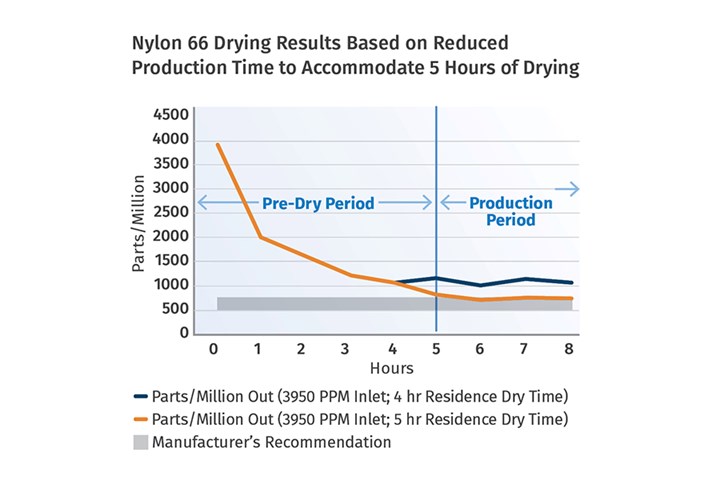

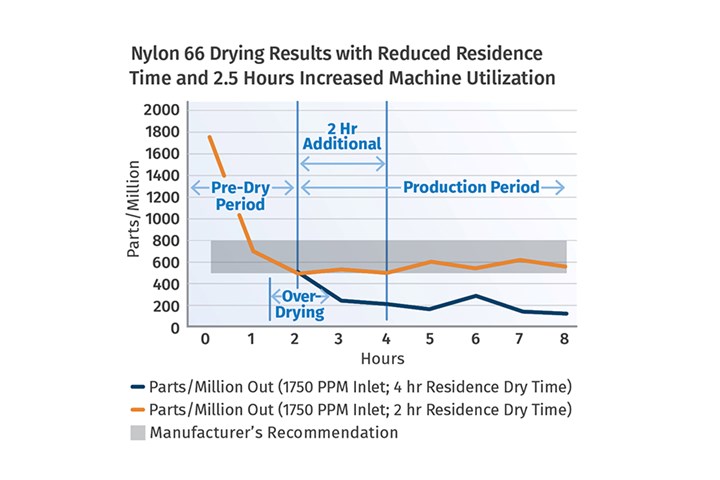

Perhaps most crucially, throwing away the resin company cookbook and instead relying on real-time moisture readings and dryer adjustments could very well result in increased capacity utilization of molding machines. Referring to the two gaylords of nylon 66 delivered to him with vastly different moisture ppm readings, Haynie notes, “If the molder followed the recipe and dried the gaylord of resin with a moisture level 1750 ppm the same time and temperature as the one with 4000 ppm, it most likely overcooked the material. We know that happens.

“And consider also that if the nylon 66 that came in with 1750 ppm needed only two hours of drying instead of four, that is two more hours of machine time the molder would have to make parts. If you know the moisture is already low in the resin, you can start making parts sooner.”

Home screen for Genie-equipped dryer, indicating the actual processing rate, target resin moisture, the residence time and the gaylord moisture level.

On rollout, Novatec will focus on gaylord applications. In the works are systems that will apply the core technology to applications that feed materials from bins and silos. Novatec is also working on combination technologies of capacitance and microwave.

For more information on DryerGenie please visit Novatec's website or PT’s Moisture & Resin Drying Knowledge Center.