NPE 2000 News Wrap-Up: Engineering Thermoplastics

NPE 2000 saw the debut of many new nylons, ranging from 6 and 66 types that are tougher, easier to process, and lower in density to a brand-new class of branched nylons with outstanding physical and rheological properties and a long-carbon-fiber grade that combines high electrical shielding with flame retardance.Also new at the show were extrusion-grade and reinforced PPS, new PPS alloys, and new sources of high-heat, reinforced polyphthalamide, PEEK, and syndiotactic polystyrene compounds.

NPE 2000 saw the debut of many new nylons, ranging from 6 and 66 types that are tougher, easier to process, and lower in density to a brand-new class of branched nylons with outstanding physical and rheological properties and a long-carbon-fiber grade that combines high electrical shielding with flame retardance.

Also new at the show were extrusion-grade and reinforced PPS, new PPS alloys, and new sources of high-heat, reinforced polyphthalamide, PEEK, and syndiotactic polystyrene compounds. Plateable high-density PBT, transparent PEI/PET blends, improved weatherable ASA, and a new generation of FR PC/ABS blends also made their debut. Also of interest are an easy-to-process fluoropolymer, an “ultra-ultra” HMW-PE, new TPOs and TPUs, and a new styrenic TPE for food packaging.Lots New in Nylon 6 & 66

New Zytel Super Tough nylon 66, available this month from DuPont Engineering Polymers, Wilmington, Del., is said to sharply reduce mold deposits, cut cycle times by 5% to 25%, improve part appearance, and reduce clamp-pressure requirements. Product manager Greg Corda says this is a “reinvention” of the company’s toughened nylon 66 resins (older grades of which will be phased out). By modifying the nylon backbone, DuPont has come up with an unreinforced nylon that can be molded at 25 to 40% lower injection pressure and 20 to 40° F lower melt temperature than comparable toughened nylons. It also reportedly produces parts such as fuel tanks with 30% to 50% higher weld strength.

There are currently four new grades—two super-tough and two medium-tough—all available in heat-stabilized and outdoor-weatherable versions. They cost no more than existing toughened grades.

BASF Corp., Mt. Olive, N.J., introduced heat-stabilized Ultramid B3WGM24 nylon 6, a glass/mineral-reinforced compound for auto door handles, mirror housings, roof racks, and engine covers. This material uses only 30% reinforcement, vs. 40% for the existing Ultramid B3GM35 grade. The result is about 8% lower density (1.38 vs. 1.48 g/cc) and easier flow, according to BASF. However, the new grade still has higher stiffness (1,189,000 versus 1,160,000 psi) due to the proprietary filler blend.

A recycled version of this new compound, Ultramid B3WGM24 RC, is made with 25% post-industrial and post-consumer content. Mechanical properties reportedly are unchanged.

BASF also supplemented its Ultramid B3GM24 metallic-appearance nylon 6 with grades that can have either a darker, steel-like appearance or a lighter aluminum finish. Metallic effects are also available in nylon 66.

Non-Halogen FR Nylons

Lati USA, Inc., Mt. Pleasant, S.C., has introduced two new 25% glass-filled, heat-stabilized, flame-retardant nylon 66 compounds for electrical and electronic applications where high glow-wire test values are required (such as by the new European IEC 695-2-1 standard). Latamid 66 H2 G/25-V1AF achieves a UL 94V-0 rating without halogen or red phosphorous. Latamid 66H2 G/25-V1AF is halogenated but contains no antimony trioxide. They offer CTIs of 450 and 300 v, respectively.

Polyphthalamides

High-temperature nylons called polyphthalamides (PPAs) are available from a new source. EMS-Chemie, Sumter, S.C., introduced the Grivory HT-PPA family of reinforced PPAs, available in flame-retardant (halogen and non-halogen) grades. They compete with BP Amoco’s Amodel polyphthalamide and DuPont’s Zytel HTN. Five injection molding grades in natural and black have 30% to 60% glass or 40% mineral reinforcement.

‘Branched’ Nylon

Rhodia Engineering Plastics, Farmington Hills, Mich., unveiled what it described as a new class of nylon that offers an outstanding combination of physical and rheological properties. While it resembles a nylon 6 in overall properties, TechnylStar nylon is based on proprietary polymerization and compounding technology. It is said to produce a new arrangement of the nylon’s molecular chain, creating a non-linear, “branched” structure.

It reportedly offers outstanding flow and excellent molded surface finish. Rhodia says it can be reinforced up to 65%, creating materials with very high stiffness and dimensional stability at elevated temperatures. The company has started to produce these materials in Europe and plans future production in North America and Asia.

Rhodia is offering very high-flow grades with 20-40% reinforcement. These are said to provide faster cycle times with smaller runners and fewer gates on large parts. Initial offerings also include TechnylStar SX heavily reinforced (50-65%) grades, which can match the stiffness of higher cost PPA, polyarylamide, and PPS but are lower cost and easier to mold. The highly filled versions are also said to register at least 50% improvement in spiral-flow tests when compared with similarly loaded grades of polyarylamide or nylons.

FR Nylon Gives Electrical Shielding

Celstran PS66-CF30-10 is a modified nylon 66 containing 11-mm long-carbon fiber. It is said to combine high electrical shielding with UL 94V-0 flame resistance. Ticona of Summit, N.J., offers this stiff, tough, black material for electrical/electronic housings.

Self-Lubricating Acetal

Lubri-Tech ATH-XC361E is a self-lubricating acetal homopolymer for injection molding and extrusion from M.A. Hanna Engineered Materials, Norcross, Ga. It contains both silicone and PTFE lubricants and is said to provide a significant cost advantage over acetals lubricated with PTFE alone. Moreover, Lubri-Tech is said to offer equivalent mechanical properties for applications such as gears, bearings, springs, and slides.

New PPS Grades & Alloys

The first extrusion grade of Ryton PPS was launched by the newly formed Chevron Phillips Chemical Co., Houston. R-6-010NA is an ultra-HMW, unreinforced compound for extruding pipe and tubing used in chemical plants, flue-gas filtration, HVAC, and automotive fuel handling. It is designed to replace metals and fluoropolymers. The 45-MFI material has a brown color, melting point of 545 F, and HDT of 220 F at 264 psi.

Also new is Ryton R11-520BL, a glass-reinforced compound formulated with sufficient electrical conductivity for electrostatic dissipation (ESD). Its volume resistivity is 100,000 ohm-cm.

Chevron Phillips also introduced the Xtel family of high-performance PPS alloys, designed to compete with more costly LCPs in industrial and automotive electrical/electronic applications. These proprietary alloys reportedly match essential properties of LCPs but cost about half as much. For example, 40% glass-filled Xtel XK2040 has tensile strength of 25,000 psi, identical to 30%-glass LCP and only slightly less than the 28,000 psi of 40% glass-filled PPS alone.

Now available in four black and natural grades, Xtel alloys can be molded at moderate pressures in water-heated molds. They reportedly flow much like LCP at mold temperatures of 150-275 F. Glass/mineral grades are in development.

PEEK from a New Source

Gatone is a new family of PEEK resins from India’s Gharda Chemicals Ltd. Distributed here by Franklin Polymers, Inc., Pitman, N.J., these are the only other PEEK resins besides those from Victrex USA, Inc., West Chester, Pa. Gharda is currently producing semi-commercial quantities at a 120,000-lb/yr unit in Bombay. A larger plant is scheduled to start up by the third quarter of 2002. List price of Gatone PEEK is $30/lb, but Gharda says it will go down when full production is under way.

The Gatone PEEK family includes a low-viscosity, high-flow grade for thin-wall injection molding; a medium-viscosity, general-purpose grade for injection molding; and a high-viscosity grade for extrusion and molding. Grades with 10% to 40% glass or carbon fiber are available in natural or other colors.

Plateable ‘Heavy’ PBT

A new plateable Valox PBT from GE Plastics, Pittsfield, Mass., has high density to give the look and feel of metal. Proprietary fillers give it a specific gravity of 5.0. Valox NBV401 boasts high tensile elongation, excellent ductility for thin-wall parts, smooth and glossy finish, and good processability. It is used primarily for injection molding cosmetics bottles and caps, kitchen and bathroom fixtures, and vanity and desktop accessories. It is being evaluated for x-ray equipment parts that require EMI shielding. It also comes in 12 colors for non-plated applications.

Improved Weatherable ASA

Centrex 825 and 833 are two improved, impact-modified, high-gloss ASA polymers from Bayer Corp., Pittsburgh. Natural color of these resins is said to be lighter and more consistent, allowing use of less pigment for coloring. In addition, Centrex 825 is designed to flow more easily with ABS in coex sheet, while retaining impact strength and providing Class-A surface and depth of image.

New FR-PC/ABS

The Bayblend 3000 series from Bayer Corp. is a new generation of flame-retardant PC/ABS blends designed for molding thin-wall electronic-equipment parts. Commercially available this fall, Bayblend FR 3000, 3010, and 3020 will have improved hydrolytic stability and reduced volatiles for cleaner processing. They have UL 94V-0 ratings at 1.2 mm (FR 3020) or 1.6 mm (FR 3000 and FR 3010). Like their FR 2000 predecessors, they contain no antimony or halogen.

FR 3000 is an easy-flowing, g-p grade for laptops, printers, monitors, and desktop systems. FR 3010 is a high-heat version for internal parts such as electrical enclosures. Specialty grade FR 3020 is said to offer improved ignition resistance for thinner walls of notebook and handheld computers.

Clear PEI /PET Blend

Ultem 1285 is a new transparent PEI/PET blend for food-service industry applications. Like other Ultem blends from GE Plastics, Pittsfield, Mass., it is designed to fill a performance gap between polycarbonate and pure polyetherimide. The new blend gives food-service manufacturers a colorable, transparent material that’s lighter, more durable, and safer than glass. It can withstand temperatures as high as 490 F. It comes in several transparent tints. The current grade is based on Ultem 1000. New grades in development will be based on Ultem 6000, a PEI with a different backbone that withstands up to 420 F. Still others will be based on a new PEI to be launched this year that has heat resistance up to 480 F. It will be geared for dual-ovenable applications.

‘Eco’ FR PPO, PC, ABS

To meet increasingly stringent global fire-safety and environmental standards, GE Plastics, Pittsfield, Mass., has applied its “eco-compliant” flame-resistance technology to several of its engineering thermoplastics. Free of both halogens and heavy-metal pigments, these new compounds reportedly meet the TCO99 eco-label standard in European and Asian markets.

“Eco” versions are now available for the entire line of Noryl PPO resins and some grades of Lexan polycarbonate—notably the 900 series for telecommunications and 900A series for appliances. They are said to closely match existing FR Lexan in processing, toughness, heat resistance, and transparency.

There are also eco-compliant Cycoloy ABS/PC grades. They are said to offer an unparalleled balance of flow and impact and typically involve no increased cost for eco-compliance. Increased flow and ductility are said to allow for thin walls and faster cycles.

Fluoropolymer Is Gentler To Your Machines

Dyneon HTE is a new terpolymer of hexafluoropropylene, tetrafluoroethylene, and ethylene from Dyneon LLC, Oakdale, Minn. The first grade, E-14659, processes at a relatively low temperature—500 F at the die—which reportedly eliminates the need for costly corrosion-resistant processing equipment. It boasts good electrical insulating properties, good tensile strength, and excellent chemical resistance. The material has been used to make loose-fit film liners for industrial chemical tanks. It is said to perform better than PVC, which begins to degrade at around 340 F, has poorer chemical resistance, and is susceptible to plasticizer migration and subsequent flex cracking. Dyneon HTE film can be extruded down to 20 mils thick with the same puncture resistance as 50-mil PVC film liners.

Dyneon HTE is weldable to itself, allowing easy installation of tank liners made from HTE film. Due to its excellent electrical insulation properties, it is also aimed at wire and cable. Dielectric constant is 2.3 at 1 MHz (23 C and 80 C) and dissipation factor is 0.004 at 1 MHz and 0.008 at 100 MHz. It also has tensile strength of 5600 psi, flex modulus of 175,000 psi, 66 Shore D hardness, Tg of 149 F, and TGA decomposition temperature of 883 F.

News in Syndiotactic PS

Four new Questra EA series ignition-resistant syndiotactic polystyrene (SPS) engineering resins were unveiled by Dow Plastics, Midland, Mich. Compared with earlier grades EA 513 (30% glass) and 514 (40% glass), the four new ones boast better impact and other mechanical properties and improved cost/performance. New EA 522 (22% glass) and EA 528 (30% glass) are said to be cost-competitive with PBT for E/E components such as connectors and auto under-hood parts. New EA 535 (30% glass) and EA 540 (40% glass) compete with PPS and LCPs.

Under license from Dow, Lati USA, Mt. Pleasant, S.C., has come out with a 30%-glass, UL 94V-0 SPS compound that is free of PBB and PBDE bromine compounds. Laestra G/30-VO CT1 is designed for E/E applications like connectors, fuse holders, and circuit-breaker housings.

PE Boasts Highest MW

GUR 4170 is a new “ultra-ultra-high-molecular-weight” PE from Ticona. It is said to have the highest molecular weight of any commercial UHMW-PE. Its MW is 7 million, vs. 3 to 6 million for other grades, providing extra wear resistance.

TPOs, TPUs, TPEs

New Flexathene high-stiffness TPOs for tough, weather-resistant, unpainted components of cars, recreational vehicles, and farm equipment were introduced by Equistar Chemicals. The TPOs can be pigmented to provide metallic, stone, and pearlescent effects. What’s more, proprietary technology has been developed by Polybond, Inc., Kingston, Mich., to laminate thin, transparent fluoropolymer film to Flexathene sheet. The laminates reportedly have excellent depth of luster, excellent fade and scratch resistance, and very high impact strength at low temperatures.

New TPOs include TP 1201-TC for sheet extrusion and deep-draw thermoforming. It can also be blow molded. At -22 F, it boasts a notched Izod impact of 1.2 ft-lb/in. and unnotched Izod of 32 ft-lb/in. These are said to be high values, considering its flexural modulus of 250,000 psi.

Also new is TP 4346-HS, a high-impact grade formulated for thin-wall injection molding. It also boasts excellent paint adhesion. Fluoropolymer film can be adhered to TP 4346-HS using an in-mold bonding technique similar to that used for decorating parts with preprinted films.

Montell Polyolefins, Wilmington, Del., developed new Hifax XFBR712 for the all-TPO instrument panel in the 2000 Ford Focus. This is the first all-TPO IP (including knee bolster and glove box) in the U.S. auto market. Made with Montell’s Catalloy process, this medium-flow (6 MFI), high-modulus (261,000 psi), mineral-filled grade is said to provide a 30% weight reduction versus PC/ABS, along with easier processing and improved acoustical performance. It has notched Izod impact of 34 kJ/m2 at 23 C and 3 kJ/m2 at –40 C. HDT is 212 F at 66 psi.

New high-resiliency/high-rebound polyether and polyester TPUs are said to approach the compression-set resistance of natural rubber while maintaining superior heat resistance. These new soft Estane injection molding and extrusion grades from BFGoodrich Co., Cleveland (70 to 85 Shore A) reportedly have more than 40% higher rebound factor than traditional TPUs. They also boast superior tensile strength and high tear and abrasion resistance over a broader temperature range.

New harder Estane grades (47 to 57 Shore D) are said to deliver superior burst strength and processability in extrusion of industrial and consumer tubing.

Kraton D1401P is a new FDA-grade styrenic block copolymer from Kraton Polymers, Houston. This tough, high-clarity TPE is similar to K-Resin from Chevron Phillips Chemical. Like K-Resin, it is blended with crystal PS to make thermoformed airline drinking cups—a new application for Kraton. It is used at levels of only 25%.

Related Content

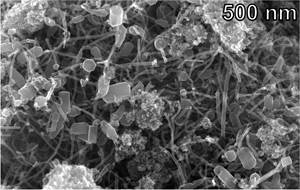

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More