NPE 2006 News Wrap-Up: Blow Molding

Among new blow molding developments at the show was an innovative coextrusion system for the growing small-engine fuel tank market.

Among new blow molding developments at the show was an innovative coextrusion system for the growing small-engine fuel tank market. Also featured were new technologies to produce multilayer injection-blown containers and upgraded stretch-blow units for ever-higher outputs. NPE also saw the emergence of a new control method for injection-blow and a bottle inspection unit that offers unusually broad quality-testing capabilities. Many other machine introductions were covered in our May and June show previews but are not repeated here.

Focus on small tanks

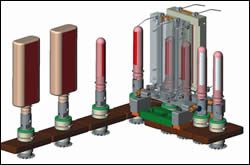

Kautex Machines announced new coextrusion blow machines specifically for production of small-engine fuel tanks. The company has joined the growing ranks of machine builders that have launched new six-layer machines for this emerging market. As we reported in April, stricter fuel-permeation regulations are pushing adoption of new barrier options for portable fuel containers (jerry cans) and small fuel tanks.

Kautex’s new KBSmart 61 Coex is a smaller version of its six-layer automotive fuel-tank machine but is aimed at small HDPE tanks for ATVs, snowmobiles, golf carts, and watercraft. It is available as a single- or double-station machine with stationary clamps and parison transfer by a six-axis robot. Clamps are positioned below the gantry to reduce the overall footprint. A new six-layer parison head, model CP 250, was developed to match the lower throughput and smaller die diameters required for small fuel tanks. With less heating capacity, the new head operates more efficiently, according to Kautex. Downsized extruders are equipped with water-cooled, maintenance-free AC drives for significant energy savings. The KBSmart 61 produces fuel tanks up to 35 liters at 55 to 70 tanks/cavity/hr.

Kautex has also expanded its horizontal 3D blow molding line. Design improvements have resulted in a 30% smaller footprint for the new K3D-HP double-station unit. This compact model has a CP120-7S coex head that accommodates a seventh layer for the electrically conductive material required in fuel filler pipes. In addition to a radial wall-thickness distribution system, the machine has a layer-thickness control system that measures the top and bottom flash weight and the net article weight to ensure that wall thickness is uniform over long production runs.

Kautex recently delivered one of these machines to TI Automotive together with a fully automatic finishing line, which removes flash from filler-pipe necks, controls the part weight, labels the articles for traceability, and cools them before oriented transfer to downstream welding equipment.

Multilayer injection-blow

Two companies highlighted the novel use of injection-blow molding for multilayer barrier containers. Coinjection-blown bottles of polycarbonate, PP, or HDPE combined with gas-barrier materials have found limited use to date but are viewed as a growth area in medical and pharmaceutical applications. Kortec, a specialist in PET preform coinjection systems for stretch-blown containers, has expanded its focus beyond food and beverage bottles and is now making headway in injection-blow. Its 2004 alliance with Uniloy Milacron has been expanded to include engineering-resin maker GE Plastics. A special 85-ton Uniloy/Kortec IBS coinjection-blow unit outfitted with a second injection unit is currently housed at GE’s processing development lab in Pittsfield, Mass.

Kortec has developed special coinjection tooling and process controls to produce a three-layer parison incorporating barrier materials such as nylon, EVOH, or COC (cyclic-olefin copolymer). The initial four-cavity machine can produce bottles ranging from 80 ml to 1 liter. Kortec aims to scale up to 12 cavities, which could produce 20 to 25 million bottles/yr depending on bottle size and cycle time. The turnkey system is expected to be commercialized in several pharmaceutical applications later this year, according to Scott Ludwig, Kortec’s account manager for coinjection systems.

Meanwhile, MGS Mfg. Group, a molder and supplier of specialty tooling and molding accessories, discussed its patent-pending technology for coinjection-blow. MGS says it has developed a unique hot-runner and melt-delivery system “which allows you to put the second injection unit anywhere you want,” according to v.p. of engineering John Hahn. The system uses standard hot-runner components but their placement on both mold halves is unique, says Hahn. MGS is focused on three-layer barrier PET containers for medical and food packaging. The company has sold one retrofit system for a food container currently in pre-production.

NPE also saw the emergence of new control technology that increases productivity and reduces energy use for injection-blow molders. The Smart Control from Plastic World, Inc. combats two of the major problems in the injection process: (1) the buildup of clamp pressure, requiring high power consumption and lost time; and (2) air trapped in the mold under high clamp pressure. These limitations result in numerous inefficiencies in both productivity and energy use, ac cording to Plastic World president Joe Mara zita.

His firm’s Smart Control is claimed to lower energy consumption by reducing injection and clamp pressure and lowering melt temperature. It also shortens cycles due to the faster injection and shorter cooling times. The Smart Control system incorporates a PC and/or PLC controller with the company’s proprietary software and fully proportional machine hydraulics. In combination with Smart Control, Plastic World also offers Max-E-Save, a system that replaces AC motors with brushless DC servo motors for faster and even more efficient operations.

In a recent retrofit of a Whea ton 402 injection-blow molder, Plastic World cited a 27% boost in productivity and 62% reduction in electricity cost with Smart Control and Max-E-Save. The company has retrofitted several injection and injection-blow units and is interested in licensing the technology.

Upgrades for PET

Switzerland’s Mag-Plastic Machinery has added new neck-orientation and preferential-heating options to its SSB02 linear reheat stretch-blow molder. Preferential heating for oval containers utilizes a dedicated oven that is retrofittable to existing SSB02 machines. A magnetic brake stops the preform from ro tating and positions it in front of four vertical lamps for heating on two sides. Then an other magnetic system ensures proper positioning for blowing (see illustration on p. 88). The system reportedly permits precise wall-thickness distribution and optimizes preform weight for cost savings.

Mag-Plastic’s neck orientation system is said to be unique because it works with nearly all available preforms. Neck orientation offered on most other linear and rotary stretch-blow-units requires the use of special performs that have one or two notches on the neck ring. In the Mag-Plastic system, positioning is done via a servo-mechanical device, and less than 0.8 sec is needed to orient the neck thread.

Another unique option offered by Mag-Plastic is a wide-body preform loading unit for preforms with no support rings or larger bodies than the rings. These preforms, which typically could only be run on one-stage machines, can now be run on two-stage (reheat) units.

A newcomer to NPE, Taiwan’s Blowplas Technology Co. has launched its one-stage linear stretch-blow machine in North America through distributor Dima Inc. The BT-N series, available with two to five stations, is said to offer simple mechanics and easy maintenance. The machine runs up to eight cavities and produces up to 2000 containers/hr for pharmaceuticals, cosmetics, and foods.

Meanwhile, W. Amsler Equipment claims to have raised the bar in bottle inspection by introducing one of the first systems incorporating both wall-thickness comparison and color testing in a single cost-effective unit. The in-line inspection system monitors wall thickness by comparing actual material temperature to a master or “self-taught” reference point. Similarly, an ideal color is stored as a master file with allowable deviation tolerances.

The system inspects 10,000 bottles/hr and is claimed to offer greater capabilities than more costly vision systems that are limited to monitoring just shapes, said president Werner Amsler. Wall-thickness and color testing are add-on options to a basic unit for leak testing and checking for neck obstructions. Its base price is $15,000.

Related Content

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreNPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More