NPE News Wrap-Up: Materials Handling

The big show in Chicago presented more new loaders, feeders, blenders, and conveying controls than you could count. They’re more flexible, easier to maintain, and easier to control. Many are web-enabled, and some are lower in cost.

The buzzwords for new materials-handling equipment at NPE 2003 were economy, modularity, and “web-enabled.” Quicker material changeovers, faster set-ups, easier installation, longer life, and lower maintenance were equally dominant themes. New control systems added dazzling functions and communication options along with greater ease of use.

Mix and match

Big attention-getters at the show were automated systems for distributing resins from multiple sources to multiple destinations. One comes from Sterling’s brand-new Material Processing group. The SDRW rotary material-distribution valve has 10 input or output ports that are programmable through a central PLC controller. The valve can distribute 10 materials to one location or one material to 10 locations. The most common set-up puts two valve assemblies back to back, so that 10 materials can go to 10 locations, for 100 different conveying options in one compact system.

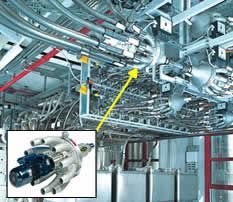

Wittmann’s Robofold takes a very different approach. This robotically actuated material-conveying manifold handles up to 15 different sources and 25 destinations. Wittmann adapted one of its three-axis injection molding robots to move the hose connections to different spots on the manifold. An electrical hose confirmation system ensures accuracy when switching lines and prevents accidental contamination. Lines are automatically purged before materials can be switched. The robot automatically opens and closes the shutoff caps that cover material lines when not in use. The system is programmed through a graphical color touchscreen, which has access to maintenance screens, complete manuals, and parts lists—all stored on a smart card. If required, programming can be done through the robot’s new ControlMax C7 pendant with its own touchscreen. Material lines can also be switched by hand.

Another new conveying manifold system is Motan’s Metrolink. It can handle up to 16 materials and 15 destinations. The system is modular and easily expandable, according to Motan. It consists of a compact, vertical stack of rotating disks. Each disk carries a pipe connection that remains attached to a single destination but turns to connect to different materials. Lines are purged automatically before each conveying cycle to avoid contamination. Metrolink can be operated by any of Motan’s new Metro A series PLC conveying controls or by its new Pocketnet wireless internet link via handheld PDA.

Load ’em up

At least 17 exhibitors brought out new hopper loaders and vacuum receivers in sizes from micro to maxi. New designs offer quick job changes, easier cleanout, more positive sealing, and “jam-proof” discharge. All-stainless construction is now virtually Universal, even on low-cost units.

For example, Molders Choice came out with low-cost, all-stainless, self-contained loaders for 132 to 396 lb/hr. Prices start at $700.

ACS Group’s relatively new Economizer unit has expanded beyond granulators to include the EconoLoad line of hopper loaders from Spain that are said to be priced 10% to 30% below the competition. Standard features include all-stainless pellet receiver, level switch, sound enclosure, and pick-up wand and hose. There’s also a choice of basic controls or a microprocessor version for proportioning virgin and regrind. Options include a proportioning valve, remote control from a pendant, and blowback filter cleaning. Three models range from 1 to 7 liters and 110 to 325 lb/hr.

Conair’s new ultra-simple, low-cost, stainless-steel Tube Loaders (see Super-Simple Loader For Low Throughputs) now are available in compressed air and central-vacuum versions.

Motan also emphasized economy in two product introductions. One was the all-stainless S series of vacuum receivers of 2 to 50 lb capacity. Receiver sizes can be changed easily by adding or removing a body section. Motan says these receivers help make central conveying more affordable. A six-station system with a blower, system filter, and PLC control starts at $8283.

Motan also upgraded its Metro SB, Metro MV, MVMS, and Metro CD central vacuum receivers. Modifications are said to extend their life and reduce maintenance. For example, hardened steel sealing plungers resist wear better than the previous polyurethane. New optional screens prevent dust carryover. Also, a new option on glass-bodied Metro MV-style receivers is a retrofittable internal sealing flap that allows the receiver to be mounted on a machine throat that cannot hold a vacuum seal. Previously, such cases required a separate hopper below the receiver.

Meanwhile, AEC introduced larger all-stainless vacuum receivers, models SRC30 and SRC60, which have capacities of 3 and 6 ft3, respectively, and enlarged (6-in.) discharge throats. Also new is a large pellet deflector to minimize filter maintenance.

Premier Pneumatics’ new Series3 2424 powder and pellet vacuum receivers are designed for high-capacity conveying and railcar or silo unloading at 5000 to 15,000 lb/hr. The 5-ft3 hopper has a 4-in. inlet, 10-in. gravity discharge gate, and 50-in.2 washable filter. Low-voltage (24VDC) controls are suitable for use with either a microprocessor or PLC controller. Low-voltage controls are also provided on the newest Series 2400 vacuum receivers.

Also for high-capacity conveying, new Hurricane P-Series receivers from K-Tron America handle colorants and other powders that flow poorly or need gentle conveying. These all-stainless units have automatic filter cleaning and capacities from 1300 to 8800 lb/hr. Models can be self-contained or central type.

Wittmann’s totally redesigned Feedmax pellet loaders can handle up to 1000 lb/hr in self-contained versions or up to 10,000 lb/hr in central-system models. Receiver capacities are 4 to 80 liters. These all-stainless units have level sensors instead of timers and also use sensors on the pneumatic discharge. A steel inlet seal replaces rubber for longer life. The new basket screen prevents pellet loss. Modular design simplifies changeover from single to dual material inlet, and a replaceable center section allows easy expansion.

The newest pellet and powder loaders from Colortronic (now a sister company of AEC and Sterling within the ACS Group) are CSP central models and CSPE self-contained, single-station types. Their automatic compressed-air cleaning is now more adjustable. Cleaning can be programmed to occur both during conveying and between cycles. Capacities are 550 to 3300 lb/hr.

Colortronic also offers new proportioning valves at a lower price ($850). They rapidly cycle an air piston to proportion virgin and regrind in numerous increments. This is said to result in less layering than with standard proportional valves.

At the opposite end of the size range, Dri-Air Industries, which recently took on U.S. distribution of the MCP line of 9-ton injection presses from England, is now offering a PLC-controlled mini loader and other auxiliaries for these machines (see Small Presses Come From a New Source).

Universal Dynamics introduced two small central-system vacuum receivers with minimum-inventory glass-tube chambers that hold 5 minutes’ worth of material at the feed throat. Models GTC-4 and GTC-8 have an air-actuated dump valve with a positive conic seal instead of the usual gravity flapper valve, which is reportedly more vulnerable to air leaks. These units are said to be unique in having a single air cylinder for both loading and discharge. They come with a level sensor and either single inlet or external dual ratio valve.

Labotek, a Danish supplier that has renewed its marketing effort in North America, showed off its relatively new Mini-Feed compressed-air pellet loaders. Capacities are 33 to 130 lb/hr. These all-stainless units come with a suction probe and an optional handheld infrared control resembling a tv remote control. It lets you set up the loader without climbing on the machine.

For small to medium-sized conveying needs, Novatec introduced the RRB self-contained, portable system for feeding up to four machines. It has the Novatouch PLC touchpanel control and Windows-based programming. It also includes a vacuum breaker valve, regenerative blower, and cartridge filter. The quiet, compact unit has no drive belts and requires no lubrication.

Novatec also added quick-release clamps to all its machine-mount JIT vacuum loaders and vacuum chambers. They now can be disassembled quickly for easy cleaning. Also new is an optional drop-in dump valve for these all-stainless units.

Plastrac brought out stand-alone loaders for small to medium-size presses. Each loader has its own controller with audible non-fill alarm.

For medium-volume needs, Una-Dyn’s new LS-95E self-contained, beside-the-press loaders handle either 300 or 950 lb/hr. The all-stainless chamber has no pellet-retaining ledges or internal seams. Simple on/off controls have fixed load/unload times. They come with a protective stand, glass window in the hopper, and improved “jam-proof” flapper valve.

Una-Dyn also unveiled its Dustmaster bag-style floor filter with self-aligning permanent gasket seal, solid-body construction, and quick-release lid. A reportedly unique feature is the ability to remove the six bags individually or as a group (see photo).

Sterling Material Processing brought out a whole line of loaders for stand-alone and central uses. Capacities run 0.5 to 170 liters. Central-system models are SSK vacuum or vacuum/pressure loaders and SSP powder loaders. Small self-contained units are SSE pellet loaders, SSPE models for powder/regrind, and SSV compressed-air, minimum-inventory models.

Options include dedusting modules for regrind and wear-resistant valves for abrasive materials. Units are expandable with the aid of extension modules. Access doors are standard, so disassembly is not required for cleanout.

From Hamilton Avtec come redesigned hopper loaders that are completely modular—users can change hopper capacity or switch from ratio to single-tube operation. A new “jam-proof,” air-operated cone discharge valve replaces the usual flapper. A new mechanical level sensor is immune to heat and needs no maintenance.

A new ratio loader for virgin and regrind from Thoreson-McCosh has an internal auger to prevent material layering.

New from L-R Systems is the PR- Series of vacuum receivers for hard-to-handle powders and regrind. They have self-cleaning filters, a special clamp ring to ensure air-tight seals, and easily expandable modular design. They are available with a variety of discharge valves, level sensors, and materials of construction.

And Walton/Stout brought out modular Turbo loading systems. They’re economical and compact—half the size of comparable models. The systems have two vacuum pumps, integral filter, and either an integral timer and control or a remote-control interface.

Conveying controls

A large number of new conveying-system controls, from simple to complex, appeared at NPE. They are based on PLCs or on PCs, which some suppliers claim are easier to use. Most have color touchscreens and some are equipped for internet communication.

AEC has three new VacTrac controls. The 2/20 and 3/33 models are basic systems for up to two pumps and 20 loaders or three pumps and 33 loaders, respectively. They have hard-wired local I/O, Allen-Bradley PLC, color touchscreen, basic diagnostics, time- or volume-based filling, and prioritized station loading. The more advanced 4/32 controller (four pumps, 32 stations) adds a color touchscreen with full diagnostics.

Conair exhibited a new family of conveying controls that offer a wide range of modular choices at different levels of cost, sophistication, flexibility, and ease of installation. They use the Allen-Bradley family of Logix PLCs, touchscreen interfaces, and DeviceNet distributed I/O architecture. Systems start at around $2400 for a small, basic B32 control system with traditional centralized I/O. It has a MicroLogix PLC able to control up to eight pumps and 32 loaders. This system also comes in a B32D version with distributed I/O for reduced field-wiring requirements and up to 35% lower installation costs. An ArmorBlock I/O module near each loader simply clamps onto the flat DeviceNet cable that connects all stations to the central controller.

The next level is the Intelligent Loading System (ILS) with ControlLogix or CompactLogix PLC, DeviceNet distributed I/O, and control of up to 96 (or more) stations.

For plants that may be growing in stages or are organized in cells of up to 32 loaders, Conair’s new “semi-distributed” version of the ILS offers some of the reduced wiring cost of a distributed system plus lower hardware costs. In this case, each cell has clusters of I/O modules that are hardwired to the loaders, but each cluster can be linked to the main controller by DeviceNet flat cable.

Foremost Machine Builders has a new family of loader controls. The basic Format V-PLC uses a small Allen-Bradley PLC to set loading parameters for a single stand-alone loader. It comes in 24V and 120V versions. A vacuum chamber with the control starts at $970. The next step up (for about $120 more) is the Format V-Micro, a microprocessor-based version that can send material usage data to a remote computer. For multiple stations, the new Format V-Multi is a microprocessor-based, non-PLC type with a touchscreen that controls two pumps and 14 stations. It is expandable in increments of similar capacity. Price is $2970.

Hamilton Avtec’s new Meridian II central loading control has a color touchscreen, Windows CE-based software, online user manuals, self-diagnostics, and internet communications for remote monitoring and servicing. It also can send and receive e-mail. This networkable control can be accessed from a PC anywhere in the plant. It costs about $5000 plus $400 per loading station.

Labotek recently installed its first new-generation central control system in North America. This Windows NT-based system is operating at Winzeler Gear’s injection molding plant in Chicago. It provides complete control and monitoring of materials drying and conveying (and metering/blending, if needed). The graphical color touchscreen control, which can be monitored from remote PCs and integrated with plant MES or ERP systems, provides data collection, real-time and historical trending, and alarms. Communications are integrated by a single-wire Profibus network. A Laborweb internet module (standard on all the company’s new controls) permits remote troubleshooting. (At Winzeler, Labotek also supplied the conveying manifold that can deliver up to 20 different materials to 100 machines, conveying lines with ceramic-coated bends to resist wear, and six dryers with their own touchscreen controller.)

Motan switched from Allen-Bradley to Mitsubishi PLCs for its new Metro A series central conveying controls. These have graphical color touchscreens in a choice of sizes, “first-in/first-out” filling sequence, fill-fault alarm, on-screen help, and a number of options: Ethernet communications, Pocketnet, remote panels, and material connection proofing. These controls also come in a Metronet version with fieldbus and distributed I/O instead of traditional hardwiring. That is said to cut electrical installation costs by up to 80%, make expansion easier, and simplify troubleshooting.

Also new from Motan is the Pocketnet wireless internet option. It allows materials-handling systems to be controlled from a pocket PC or PDA. A wireless access point (WAP) can be installed on Motan’s Metro A series drying and conveying controls. This allows a user to view the same displays on the PDA as on the main control touchscreen and also to adjust fill times, purge times, regrind ratios, etc. The PDA with software costs around $7000, and the WAP adds about $1000 to a loader or dryer control.

Mould-Tek showed off its relatively new T-Link system that monitors and controls a network of loaders from a central touchscreen. Communication is by RS485 twisted-pair wiring and 24VDC. T-Link can be combined with the firm’s new T-Com2 PC remote-control network for blenders.

Novatec is now offering its NovaTouch touchscreen PLC control—previously available only on dryers—for its blenders and conveying systems. It comes with modem and fieldbus options.

A PLC controller for up to 48 vacuum receivers and four blowers is new from Premier Pneumatics.

Sterling Material Processing offers a family of Mitsubishi PLC central conveying controls—from a basic one-pump/four-station system up to color touchscreen models for seven pumps and 50 stations. A PC package provides data acquisition.

The latest generation of the Echo Millennium control and monitoring system from Universal Dynamics is a PC Windows-based network for local and/or remote control and monitoring. Almost any SPI-compatible equipment can be added to this distributed-I/O, “plug-and-play,” two-wire network—loaders, dryers, blenders, chillers, and mold-temperature controllers. Each component is uniquely identified by its SPI-protocol address, so it can be plugged in anywhere. No programming is needed—just a few keystrokes are enough to identify a new piece of hardware or reconfigure the system. The color touchscreen display shows screens for a whole plant, individual cells or departments, and individual pieces of equipment within a cell. Photos or drawings of machines can be inserted into screen displays. The system can graph critical process variables, monitor any changes, and generate reports of material usage, preventive maintenance, run time, and system status. Factory-direct support is available via modem and e-mail.

Another software enhancement is called Process Chain Verification. This is a set of user-defined configuration menus that ensure the right material gets to the right machine. By early 2004 it will be possible to scan a mold and machine with a wireless barcode reader to inform the system of which material is required. The “process chain” also documents which auxiliaries (blenders, chillers, dryers) are required and specifies ratio and temperature settings. System cost is less than $3000 for the basic software plus another $200 to $500 to interface each loader or dryer.

Wittmann displayed two levels of controls for materials handling. One is a new low-cost, entry-level system. It’s a direct-wired, 24V package that includes 10-station control and touchscreen programming for the same price as mere indicator lights and switches.

In addition, Wittmann showed off its relatively new WittLink option that allows remote monitoring and troubleshooting of any of its auxiliary equipment from any PC via the internet. It requires the addition of a web-server card to the controller and PC software for the monitoring station.

Feeding the process

Three firms introduced feeders with a flexible polyurethane inner liner that is mechanically “massaged” to ensure steady feeding. Brabender Technologie introduced its FlexWall Plus feeders with “Easy Change” design. The hopper, screw, and tube can be removed in seconds. Single- and twin-screw modules are also interchangeable. The feeder comes in volumetric and gravimetric versions. As reported previously, similar features are provided in Colortronic’s new C-Flex feeder (see Flex-Wall Feeder Keeps Powders Moving) and K-Tron’s new Quick Change/Quick Clean feeder with compact Shear Hopper (see Quick-Change Feeder and Compact Hopper Agitator).

K-Tron’s newest crop of feeders also includes combinations of its K2 modular units with Hurricane P-series vacuum receivers. The combined units can be used in volumetric, gain-in-weight, and loss-in-weight applications.

K-Tron also came out with a Smart HIPO module for its SmartConnex controls. It is described as a simple and economical controller for a single continuous gravimetric feeder. It comes with new Screw-Speed Modulation software to smooth out fluctuations in feeding. It controls refill of Hurricane loaders or central receivers.

Colortronic introduced the new C2 Megatouch control system for up to three lines with up to four gravimetric feeders each. Just touch the image of a feeder on a screen to call up its set-up screen. The system also compares actual feeder performance to setpoint.

New feeders and controls were also shown by Process Control Corp. Its all-stainless, ultra-low-rate gravimetric powder feeders handle 0.2 to 80 lb/hr (see Feed Powders at Ultra-Low Rates). The company also announced new digital signal-processing technology that is said to be the first to filter out line-voltage “noise” in the 50 to 60 Hz range. The result is said to be unprecedented accuracy and stability—steady measurement of as little as three pellets’ weight loss.

The new AF-1-QC feeder from Novatec is designed for quick changes of the single auger and hopper. Conair’s new BFG auger feeder has a fixed hopper, which reduces its cost. L-R Systems has a new gravimetric color feeder that mounts directly on a machine’s throat.

Meanwhile, several small color and additive feeders made their debut at the show. Motan’s Minicolor volumetric auger feeder is mounted over the machine throat. It comes in three sizes of 0.2 to 44 lb/hr and with either a timed dosing cycle or a higher-level control with recipe management, automatic regrind compensation, throughput monitoring, and optional interface to a central controller.

Romax showed a new version of the Movacolor 24 additive feeder from Movacolor B.V. of the Netherlands. This device, which inserts a rotating dosing cylinder into the flow of virgin resin just above the machine throat, has a new controller that provides quicker calibration and can operate several feeders at once. The auto-calibrate feature lets you enter the desired additive percentage instead of an rpm setting, so no calculation is necessary. The controller can store 99 settings and delivers 5 g to 55 lb/hr.

Romax also exhibited a new, smaller rotary premixer, the Fabri-Dyne MM50, which fits between an additive feeder and the machine throat.

Sterling Material Processing brought its new SDD digital dosing systems for one or two additives (powder or pellet). Based on Colortronic technology, it uses a dosing disc whose speed is automatically adjusted to synchronize with the processing machine. Its control stores 10 recipes.

Una-Dyn’s new PAF Series additive feeders have lower prices (starting at $1950) and totally modular construction. New “quick clips” that hold the auger, barrel, and motor permit easy disassembly. The units dispense 0.5 to 1300 lb/hr and feed into the center of the material stream rather than its edge. They come with simple potentiometer speed control or with tachometer feedback to synchronize with the processing machine.

Weigh blenders galore

Exhibits from 10 suppliers testified to the popularity of gravimetric blenders. AEC’s new BD-2500 batch weigh blender handles up to six free-flowing materials at up to 2500 lb/hr. Its Allen-Bradley PLC stores 50 recipes. The unit is said to be easier to clean and maintain than previous models. The touchscreen panel constantly displays material usage and permits three modes of recipe entry: as a percentage of virgin, a percentage of the overall batch, and as ratios (“parts mode”). Also new is Windows-based A3 networking software, which can monitor and control up to 1000 blenders.

Foremost has an all-new CLWB-2 continuous loss-in-weight blender series for up to six materials and throughputs of 1000 to 4000 lb/hr. Modular design replaces custom-built versions, reducing the cost, which starts at $31,292. The new microprocessor control with touchscreen is less expensive than a PLC. Powders and pellets can be metered by augers or vibratory feeders. New lift-off hoppers are easy to clean.

L-R Systems has upgraded its WSB weigh-scale blenders with a color touchscreen that shows the actual weights dispensed. Throughputs have been increased by 50% or more. The company also came out with a new WSBMM series of competitively priced weigh blenders in sizes from 140 to 1000 lb/hr. They handle four materials. New features are removable color bins for fast changeovers and mixing screws to homogenize the blend.

Motan’s Gravicolor batch weigh blenders are new to the U.S. They blend up to six materials at 4000 lb/hr. PLC control is said to ensure less than 0.1% batch-weight variation. It also downloads production data to a remote computer. Small models use a vertical micro-auger that can dispense just a few pellets, while large models use double-acting conical plungers for metering.

The newest batch weigh blender from Mould-Tek Industries is the HRB-14 mini model for up to four materials and 180 lb/hr. Its color touchscreen (the first in Mould-Tek’s line) uses color coding to identify ingredients. It displays target and actual weights and deviations. It can be monitored remotely via the company’s T-Com2 Windows/PC networking software. Fast-acting pinch valves control dispensing.

Plastrac introduced a disk-based blender that combines volumetric metering with gravimetric calibration. Its Auto-Disc micro-metering blender reportedly can dispense colorant microspheres or micropellets at levels below 0.025% and provides synchronized feed rates (with no stirring) as low as 0.004 g/sec.

Process Control has enhanced its blenders with two new Windows PC software programs. Material Manager is a material usage and tracking system that produces reports for inventory control. It downloads data from up to 12 blenders to any PC and can generate reports by shift, job, blender, material, and recipe. Material Manager works with new Trend Manager software that graphs material usage.

Sterling’s new SGB Series batch blenders handle up to six free-flowing materials at 10 to 5000 lb/hr. They have a Mitsubishi PLC and a handheld control pendant with a graphical touchscreen. The controller stores 50 recipes as percentage of virgin, percentage of batch, or ratio of the batch.

Thoreson-McCosh unveiled its first batch-type loss-in-weight blenders, customized for the company by Mould-Tek. These GXB units handle 400 to 6500 lb/hr and have touchpanel controls that store 100 recipes.

TSM Control Systems has a new Micrabatch blender for four components and up 130 lb/hr. It can dispense batches down to 1 g with 0.1% or better batch-to-batch consistency. Its pneumatic mixing has no motor or moving parts. Its microprocessor control has LCD display of set and actual weights, stores 60 recipes, and provides inventory reporting.

Related Content

Technology Aims to Smarten Up Resin Conveying

At NPE2024, Novatec moves to rewrite the rules for material conveying with patent-pending smart-pump technology.

Read MoreIndustry Vet Duff Joins ACS Group

With 37 years of experience on both machinery and processor side, Michael Duff to handle aftermarket business for auxiliary equipment manufacturer.

Read MoreArtificial Intelligence Manages Changing Conveying Conditions

NPE2024: Billed as an industry first, controls autonomously adjusts the conveying system in real-time to move material under optimal conditions.

Read MoreNew Pump Rewrites Conveying Rules

NPE2024: Smart Pump technology brings more flexibility and finesse to resin conveying.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More