Seven Tips to Maximize Hot-Runner Performance

Tips & Techniques

A complex variety of factors affects the success of processing with a hot-runner system. Nevertheless, you can reduce this complexity and handle many of the issues by addressing a few key issues.

Hot-runner systems can provide an array of benefits, including reduced material use, faster cycles, and overall better part quality.

Despite these advantages, hot-runner systems are not without challenges in terms of maximizing their performance.

A complex variety of factors affects the success of processing with a hot-runner system. Nevertheless, you can reduce this complexity and handle many of the issues by addressing a few key issues.

1. MAINTAIN A FLAT THERMAL PROFILE

In some hot-runner systems, it can be difficult to keep temperatures uniform in the nozzles and tips—areas where evenly distributed heat is needed to prevent flow-channel hot spots.

With many hot-runner systems, and with certain resins, you may need to lower the temperature of the material right at the gate to prevent drooling, stringing, or other part-quality problems. Sometimes, the cause is related to a less-than-optimal match between standard heaters and the nozzles and other components of the system. Special heaters—particularly flexible heaters—that are designed specifically for compatibility with a given system will achieve better distribution of heat. On the heater head, a more heat-retaining material, such as titanium, will also help prevent heat dissipation.

Titanium is beneficial for the same reason in the nozzles and tips. However, when using an abrasive material, you may need to use a more corrosion-resistant metal, such as H13 steel, which conducts more heat. This problem can be fixed by adding a titanium collar to prevent heat dissipation.

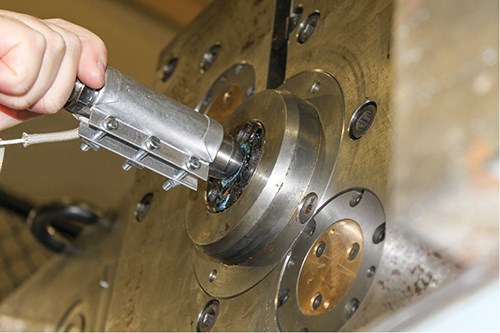

2. MINIMIZE RESIN LEAKAGE

The root cause of the vast majority of material leaks is a process temperature that exceeds the levels for which a hot-runner system is designed. When excessive thermal expansion exerts pressure on the system, something’s got to give. Components shift position, leaving room for a leak. In this case, use of compression nozzles versus threaded nozzles can be an advantage because they leave room for absorption of the expansion without placing stress on the components. This helps avoid leaks and lessen the risks of component failure over time.

Molding machine nozzle tips that aren’t properly centered in the manifold nozzle seat also can cause costly material leakage. To check your nozzle centering, try the following:

•Place a sheet of paper between the tip and the seat of the hot runner.

•Move the barrel forward so that the nozzle tip makes contact with the seat.

•Look at the paper. Is there a clean circle cut?

•If not, adjust the carriage as necessary.

3. PREVENT BUBBLING/DROOLING

Preventing plastic from bubbling out of nozzles is essential to ensuring part quality as well as prolonging the life of your molds. Bubbling is caused by either gas or material that is trying to escape the constraints of the nozzle. Gas bubbles are a sign of a hot spot in your manifold causing material off-gassing. If the gases can’t vent properly, they will bubble out of the nozzle tips.

But don’t be too quick to blame your hot runner for this problem. A closer examination will more likely reveal that the molding machine isn’t set to your material manufacturer’s recommended temperatures, causing the resin to overheat. In addition to keeping your system at proper temperatures, maintaining a flat thermal profile, as discussed previously, is the key to avoiding this issue.

Keep in mind that many of today’s advanced materials have so many additives that it’s nearly impossible to know the right machine settings and material off-gas temperatures without carefully reviewing the documentation. Previous experience working with nylon, for example, won’t necessarily help you with a different nylon formulation.

If unused material is drooling out of a hot nozzle tip, decompression of the injection cylinder may be necessary. This involves decreasing the pressure on the screw, which creates a vacuum that sucks any unused material back out of the nozzle until the next cycle. An important caveat: Too much backpressure can cause air pockets to form. And once again, that gas will need to escape somehow.

4. MAINTAIN EVEN PRESSURE

Excessively high or uneven pressure can burn material and leave silver streaks on your parts. One of the most common causes of this issue is having the wrong nozzle orifice size.

Make sure that the nozzle radius on the molding machine matches the nozzle-seat radius of the hot-runner system. If not, adjust the machine nozzle orifice appropriately. This will drop the pressure and make for easier material flow, eliminating your burning and streaking problems. Proper sizing will also prevent material drooling and create a leak-proof seal.

Nozzle orifice size is a particular concern with glass-filled resins. The wrong orifice size will cause buildup of the glass in the nozzle over time. Higher injection pressures are then required to push material through, eventually leading to flashing the mold. To prevent this problem, a good rule of thumb based on my experience is an orifice of between 1.4 and 1.5 mm for glass-filled resins.

5. START UP YOUR SYSTEM PROPERLY

In a new system, nozzle tips are among the smallest and therefore most vulnerable components when subjected to injection pressure. For this reason, it’s a good idea to backfill the system with plastic prior to the first cycle. This action helps protect the tips from fracturing, since the tips are reinforced by the surrounding plastic.

Processors are occasionally perplexed to find that material sticks to a mold at the beginning of the day. The cause may be that material was left in the hot-runner system after shutdown. This oversight can be particularly problematic when working with heat-sensitive material such as nylon. To fix the problem:

•Heat the nozzles up to compensate for loss of heat soak.

•Reduce the temperature back to normal process temperature after a few minutes to avoid overheating your material.

Occasional, gradual residue buildup in melt channels is normal. To completely eliminate the problem, you’ll need to purge your system. In the past, purging could only be done by pushing more resin through the hot runners. Fortunately, however, commodity purging compounds are available and affordable for purging after you’re done processing for the day.

6. ENSURE UNIFORM COOLING

To ensure proper cooling of all areas of a mold, you should have a water circuit for each individual cavity. We’ve seen many systems over the years where a single water circuit was feeding water jumpers to cool multiple cavities, always with less than stellar results in terms of cooling times.

7. USE THROUGH-HARDENED PINS

By using through-hardened valve-gate pins, instead of the typical case-hardened pin, you can grind down a pin to refresh it and still reuse it as it wears.

By following these tips and consulting with your hot-runner supplier, you’ll ensure that your system can improve part quality, reduce costs, increase design options, and enhance surface finish, among other benefits.

Related Content

Process Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More