Extrusion: Start Up and Shut Down Properly

A key goal during startup and shutdown of the extruder is to prevent degradation of the polymer left in the extruder and downstream components such as screen changers, adapters, and dies.

A key goal during startup and shutdown of the extruder is to prevent degradation of the polymer left in the extruder and downstream components such as screen changers, adapters, and dies. Unfortunately, there is no universal startup/shutdown procedure, as there are many different mechanisms of degradation. Some polymers degrade so quickly from heat that they cannot be left in the extruder for even a few minutes. Chlorine-containing polymers such as PVC and chlorinated polyethylene, for instance, must be fully purged before shutdown or they will break down quickly to form carbon and dangerous, corrosive chlorine gas.

For many common polymers, a careful startup and shutdown procedure will result in reduced purging and considerable material savings. Polyolefins (PE, PP, PB) and styrenics (PS, ABS, SAN), which make up a large percentage of the extruded polymers, contain high percentages of carbon and no oxygen. As a result, they are relatively stable at elevated temperature, provided there is no oxygen in the environment. With these materials, I generally recommend leaving the barrel full and shutting off all the heats as soon as production is stopped, and starting up with an intermediate setting of 200 to 250 F. Once the intermediate setting is reached, set the temperatures at normal operating settings and start up as soon as all zones have reached their setpoint.

Nitrogen-containing polymers such as nylons and urethanes are often purged with a polyolefin, which can be left in the extruder using the previously mentioned procedure. However, with close control of the heat-up time, nylons and TPUs also can be left in the extruder with minimal degradation. Polyesters, PC, and PMMA are polymers containing oxygen, so they must be entirely removed from the extruder and downstream components in order to prevent chain breakage and oxidation. They must be purged with a stable polymer such as a polyolefin if the extruder is going to be out of service for more than an hour.

Like so many aspects of polymer processing, there is no set rule. A lot of processors empty the extruder on shutdown for olefins, styrenics, and nitrogen-containing polymers. I have found this approach can actually result in more purging at startup because it allows oxygen to fill the screw and barrel and accelerate degradation of residual polymer.

I suggest trying the full-barrel procedure for these resins, but avoid raising the barrel temperature to operating settings until it is certain you can start up. If you use polymers that require daily purging, you should use one of the many purging compounds on the market suitable for that polymer, or use a polymer that is itself very thermally stable (like a polyolefin). Although stiffer (higher-viscosity) polymers or purge compounds make the best purging materials, their stiffness works against you when you try to push the purge out with the regular polymer. For the best overall efficiency in purging, I find the viscosities of the purging compound and material to be purged should be similar. To save money, processors often buy purging materials that are recycled polymers with no specified viscosity. This can actually increase your cost by increasing the purging time for the regular polymer or for the purging compound.

When purging, it is necessary to run the extruder as near to full capacity as possible. Many people purge at very low outputs. This reduces the shear stress near the metal surfaces in the entire system and thereby reduces the very forces that are needed to clean the metal surfaces in the extruder and downstream equipment. In the downstream components, low flow rates do not develop a velocity profile that maximizes the shear stress near the walls of the device. As a result, the low-output purge may clean the screw fairly well but leaves material on the walls of all the downstream components that will show up in the extrudate as soon as the system approaches production outputs. So purging should be done near the production output rate for the best result and the most economical use of both the purging compound and regular polymer.

Since all polymers and purge compounds increase in viscosity with decreasing temperature, it is advisable to lower the barrel temperatures somewhat when purging to increase the viscosity of the material. However the temperature of the downstream components should be maintained so that the more viscous extrudate can clean the walls better.

Each of these suggestions is only a minor component of improved purging, but added together they can make a significant difference. Since each extrusion line is a little different you will have to develop the best procedure by some trial and error, noting the time and amount of purge material used in each trial. Once you get the best result, stick to it.

ABOUT THE AUTHOR

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

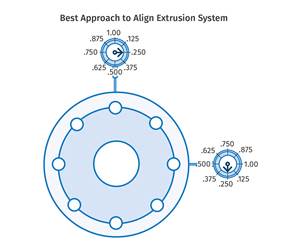

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.jpg;width=70;height=70;mode=crop)