Stop Die-Hole Freeze Off

Custom compounders use underwater pelletizers for a growing range of engineering polymers, including resins like PET, nylon, and polycarbonate that exhibit such “difficult” characteristics as low viscosity and/or rapid cooling or high melt temperature.

Custom compounders use underwater pelletizers for a growing range of engineering polymers, including resins like PET, nylon, and polycarbonate that exhibit such “difficult” characteristics as low viscosity and/or rapid cooling or high melt temperature. Underwater pelletizing has the advantages of superior pellet quality, higher automation, and often lower cost than strand pelletizing. But with engineering resins such as these, there’s a greater risk of freezing off the die than with less sensitive commodity resins like polyethylene, polypropylene, or polystyrene.

Underwater pelletizers typically use a circular die with anywhere from 10 to 20 holes up to hundreds of holes. Systems can be designed for compounding anywhere from a few hundred to nearly 20,000 lb/hr. (Even bigger pelletizers are used for resin production. The record is one built by Coperion Werner & Pfleiderer with 7750 die holes for 154,000 lb/hr of PE.)

Die holes are typically 0.125-in. diam. but can be as small as 0.01 in. diam. for micropellets or as large as 0.20 in. Output per hole runs from 25 to 100 lb/hr, but averages about 30 lb/hr with a 0.125-in. die hole.

The key to underwater pelletizing is to transport enough hot plastic through the die holes to keep the holes at the melt temperature of the resin, while the melt and die are in contact with water that’s a few hundred degrees cooler. A metal die is a very good conductor of heat, so unless polymer flow through the die hole is sufficient, the water will cool the holes, and polymer will solidify in them. The processor, however, has no immediate way of knowing this blockage has occurred. Output at first may not change perceptibly.

The problem is that if one or more die holes are plugged with polymer, the die becomes less efficient. Eventually the plugged holes affect flow through holes around them, and finished pellets become larger and irregular in shape. Production decreases. Eventually, a complete line shutdown is required to clear the die holes.

There are three major causes of die freeze-off: Improper start-up sequencing of polymer and water flow and cutter operation; inadequate die heating and insulation; and process fluctuations. Failure to consider material formulation (resin, filler level, and filler type—whether heat-absorbing or heat-conducting) can also cause problems. But you can’t change the formulation to please the pelletizer, which should be designed to run most formulations.

Automate your start-up

Most die-hole freeze-off happens during start-up when the resin, cooling water, and cutter must start in the proper sequence. If resin starts to flow through the die before the water reaches the die face and the cutter engages, smearing and resin blockage will occur outside the holes in the water box. If water gets to the die face before the polymer begins to flow, too much cooling will cause the holes to freeze off.

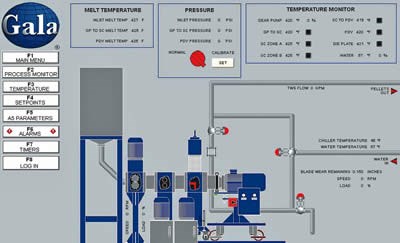

In early underwater pelletizing systems, a skilled operator controlled this sequence manually. Beginning in the early 1990s, start-up could be automated and controlled by commercially available PLC control systems. Polymer diverter valves and process-water bypass systems give a PLC even more precise control of the timing of polymer and water to the die. Pelletizers built since the mid-1990s offer automatic cutting systems using hy draulics, pneumatics, and servo motors to control cutting pressure. So today’s fully automated systems can control start-up sequence within fractions of a second.

Die-design issues

Once the line is up and running, most die freezing can be avoided by maintaining very constant material flow through the die holes. But some freeze-off problems are related to the die design itself.

Most die holes freeze off during start-up. Automated sequencing gets the water, resin, and cutting timing right. (Photo: Gala)

Dies are heated by electric cartridge heaters or hot oil. Electric heating won’t be perfectly uniform because the cartridges are placed mainly near the outer edge of the die plate in a ring around the die holes. Thus, the holes around the outside of the die tend to be hotter than holes at the center. (Die makers have tried adding cartridges in the center of the die, but the engineering proved awkward.) So cartridge heaters may not be adequate for large dies or for materials with a narrow melt-temperature range, such as nylon, which could tend to freeze off in the center of the die.

Oil heating applies more uniform heat over a larger area than cartridge heaters. Oil systems are configured with up to eight die zones. But oil heating is more expensive than cartridge heaters. Oil heat is typically used for high-output lines at resin makers or large compounders. More recently it has been offered on smaller systems for better temperature control.

If an oil valve plugs, die holes in the affected zone of the die become cooler and could freeze, but the rest of the die will be fine. Output may not change at first. Again, as with cartridge heaters, the problem will show up as defective pellets.

All dies have some type of thermal insulation. Most dies use special plates attached to the middle of the die face. But plates can come loose. Then water gets behind them, cools the die, and can cause freeze-off.

Another method of insulation is a “hollow” die design using a gap containing a vacuum. If not part of the original die-plate design, it can be retrofitted onto most systems. Vacuum is a good insulator and can’t be compromised like a solid insulation plate.

Stop hiccups

Process interruptions or output fluctuations of any kind can cause freeze-off. Extruding low-bulk-density reclaim materials can cause surging and fluctuations in extruder output, which can cause enough inconsistency in polymer flow to freeze die holes in a random fashion. A polymer melt pump can be used to prevent these surges and provide consistent die flow.

Use of a discontinuous, slide-plate screen changer also causes an interruption in flow and traps air, causing a momentary loss of polymer flow to the die holes. Random freeze-off of die holes can result. The solution is to use a continuous screen changer, which changes dirty screens on the fly without interrupting the process or trapping air.

Dana Darley has 25 years experience in plastics and is now president of Extrusion Auxiliary Services Inc. in Atlanta, which offers technical consulting for extrusion and compounding (www.extrusionauxiliary.com). He can be reached at (678) 714-5218 or e-mail dana@extrusionauxiliary.com.

Read Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More